NKBT water-based sol, binary ferroelectric and piezoelectric film prepared from the same and manufacturing method

A sol-based and water-based technology, applied in chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve the problems of human health hazards, expensive metal alkoxides, high toxicity, etc., achieve short processing time, perovskite phase The formation of stable, less pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

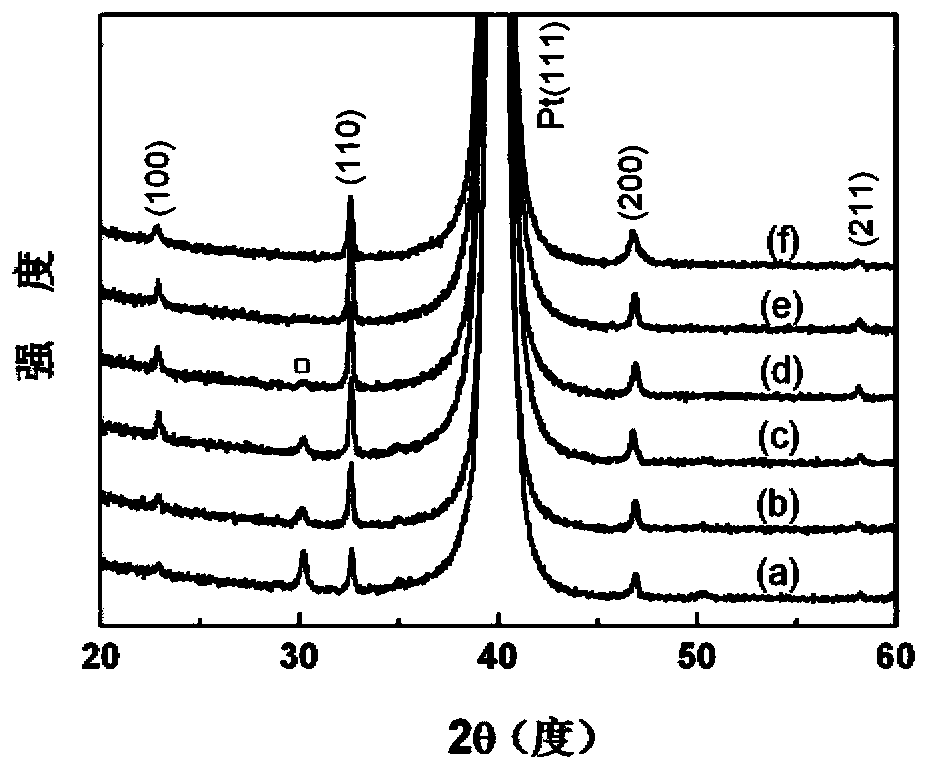

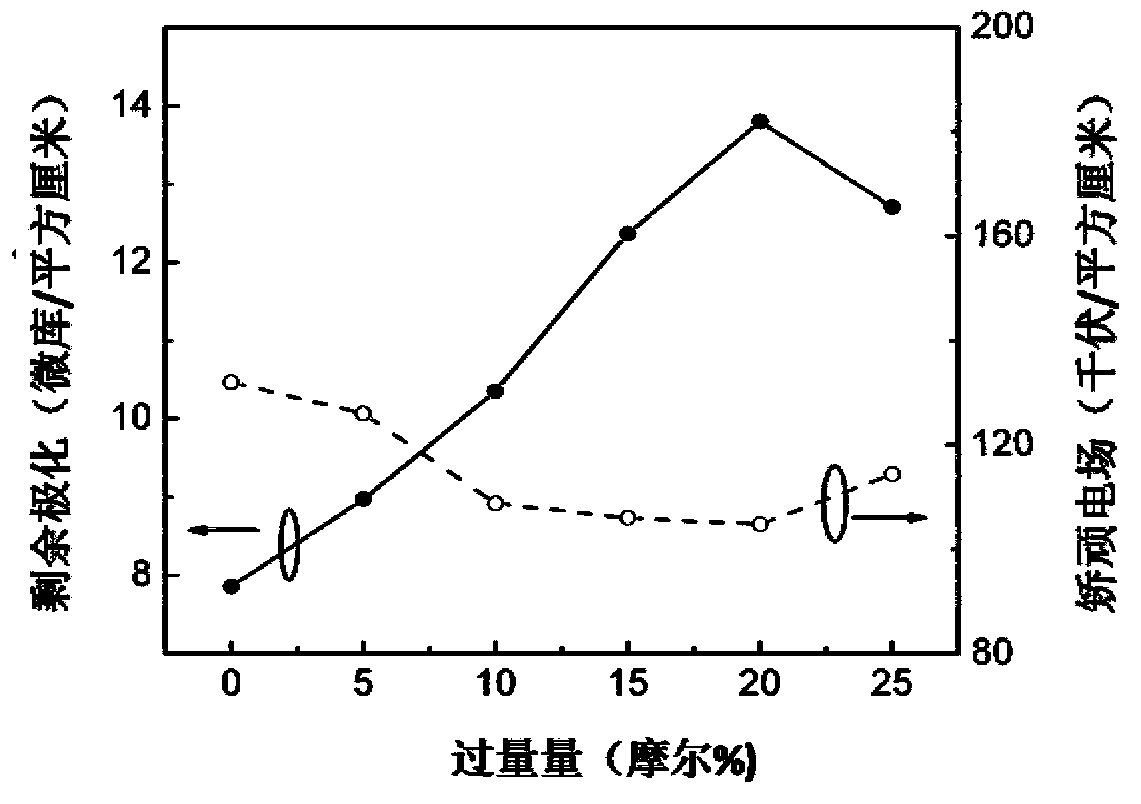

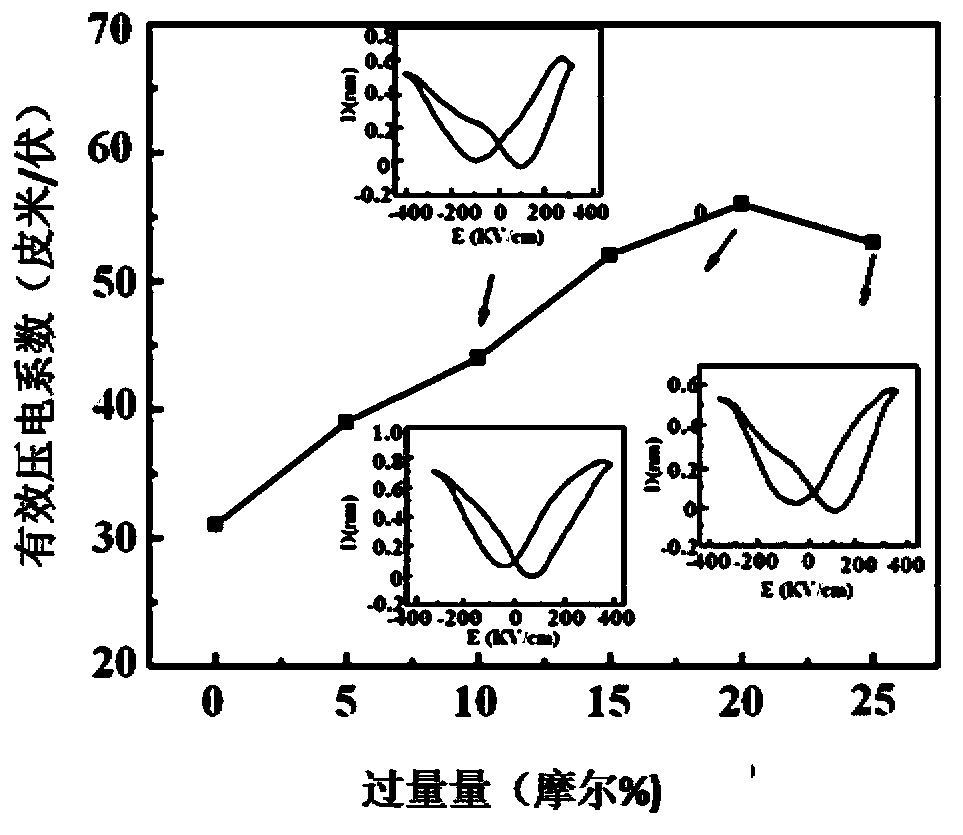

[0043] (1) Preparation of a new type of water-based NKBT sol

[0044] The starting material is preferably analytically pure sodium acetate (NaCOOCH 3 ), potassium acetate (KCOOCH 3 ), tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ), bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O). with water and glacial acetic acid (CH 3 COOH) as a solvent, while adding a small amount of isopropanol ((CH 3 ) 2 CHOH), acetylacetone (CH 3 COCHCOCH 3 ) as a stabilizer, formamide (CHONH 2 ) as a chelating agent and desiccant. At the same time, due to the volatilization of part of Bi and Na / K in the subsequent heat treatment process, a certain amount of excess bismuth nitrate and sodium acetate / potassium acetate will be added to the configuration of NKBT sol. The solvent component of the configuration is selected at the quasi-isotype phase boundary, with the best performance of 0.85 (Na 0.5 Bi 0.5 )TiO 3 -0.15(K 0.5 Bi 0.5 )TiO 3 , prepare the sol by mixing the raw materials according to this chem...

Embodiment 1

[0060] The preparation of embodiment 1 water-based NKBT sol

[0061] Step (1): Add isopropanol and acetylacetone to glacial acetic acid at a concentration of 0.72 mol / L and 0.72 mol / L respectively, and then dissolve tetrabutyl titanate at a concentration of 0.24 mol / L in the glacial acetic acid solution.

[0062] Step (2): Add bismuth nitrate to the mixture obtained in step (1), the concentration of bismuth nitrate is 0.132mol / L in terms of glacial acetic acid, and stir the solution on a homogenizer until it becomes transparent.

[0063] Step (3): in the mixture that step B obtains, add the deionized water of equal volume with glacial acetic acid as solvent, then add sodium acetate and potassium acetate, the concentration of sodium acetate and potassium acetate is as shown in table 1 in terms of glacial acetic acid, The mixture was then stirred until clear.

[0064] Table 1

[0065]

[0066] Step (4): in the solution that step C obtains, add formamide as chelating ...

Embodiment 2 2

[0067] Example 2 Preparation of Binary Ferroelectric Thin Film (1)

[0068] (1)Pt / Ti / SiO 2 / Si substrate

[0069] This embodiment adopts Pt / Ti / SiO 2 / Si substrate, the preparation process is as follows: first, p-Si silicon wafer is cleaned according to the standard CMOS process, and after drying, it is oxidized in an oxidation furnace at 1100°C for 2 hours to form SiO with a thickness of about 300nm 2 , and then use the magnetron sputtering method to sputter the bonding layer Ti and the bottom electrode layer Pt, and the resulting thicknesses of Ti and Pt are 30nm and 200nm, respectively. The sputtering process parameters of Ti bonding layer Ti and bottom electrode layer Pt are shown in Table 2.

[0070] Table 2 Typical preparation process parameters of Ti layer and bottom electrode Pt

[0071] sputtered film

Sputtering pressure

Substrate temperature

Sputtering power

Adhesive Ti

Ar

1.5Pa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com