A kind of preparation method of porous silicon nitride ceramics with low metal ion residue

A technology of silicon nitride ceramics and metal ions, which is applied in the field of preparation of porous silicon nitride ceramics, can solve the problems of high temperature performance and dielectric performance decline of porous Si ceramics, and achieves the advantages of being beneficial to industrial production, simple and easy to implement, and helpful for industrialized production. The effect of dose reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The process steps are as follows:

[0037] (1) The raw material is Si with an average particle size of 0.5 microns 3 N 4 Powder 100g, Li 2 CO 3 1.63 grams of powder (equivalent to adding 0.66 grams of Li 2 O), Y 2 o 3 Powder 0.33 gram, with absolute ethanol as mixing medium, with agate ball as grinding ball, ball mill mixing 20 hours;

[0038] (2) Dry the mixed powder and pass through a 100-mesh sieve, and mold it under a pressure of 10MPa;

[0039] (3) The formed body is sintered at 1600°C in a nitrogen atmosphere of 0.2MPa and held for 4 hours, then vacuumed to less than 1 atmosphere (relative vacuum is -0.02MPa), and then heated to 1800°C and held for 4 hours. Hour.

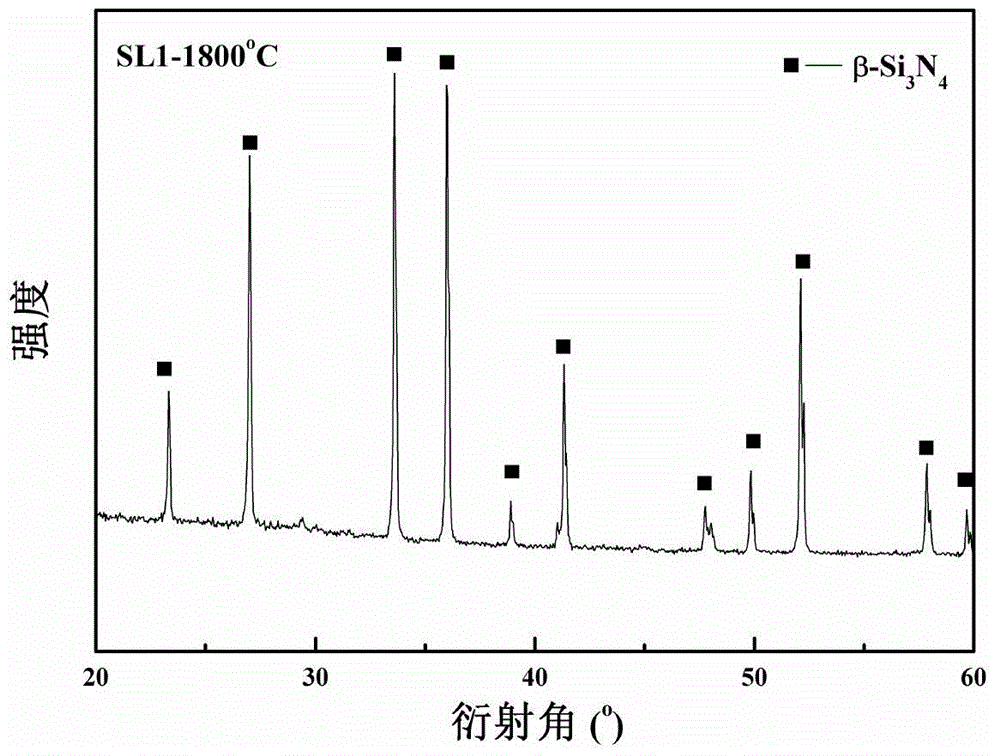

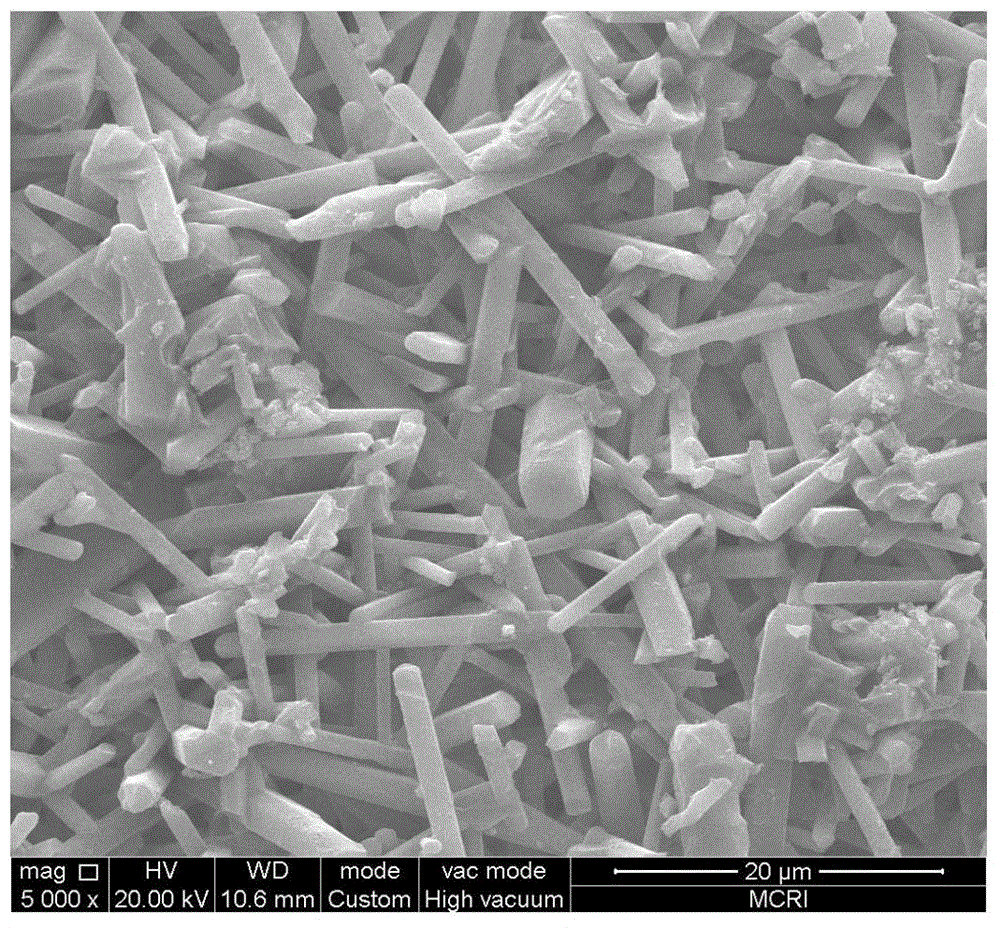

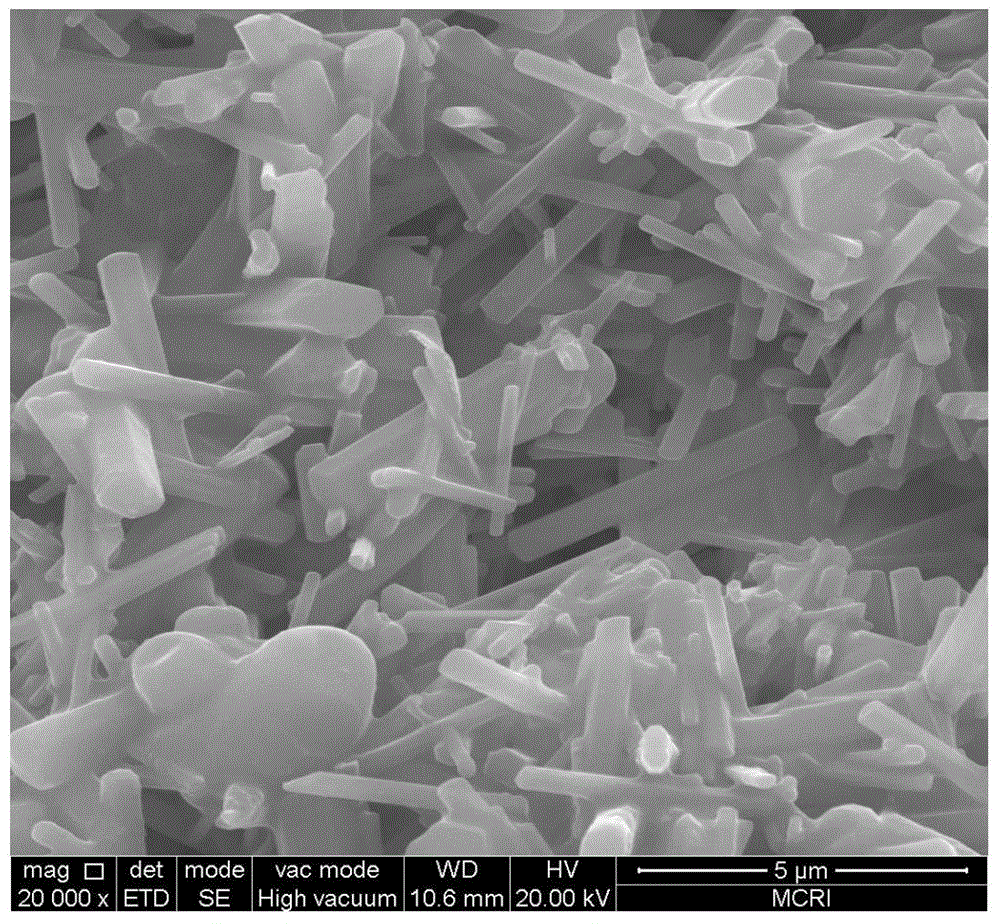

[0040] Porous Si prepared by this method 3 N 4 The X-ray diffraction pattern of ceramics is attached figure 1 , the tested material is complete β-Si 3 N 4 . The porosity measured by the Archimedes method is 54.4%. The Li content measured by inductively coupled plasma atomic emission spect...

Embodiment 2

[0042] The difference from Example 1 is that the removal of the volatile liquid phase and metal ions is accomplished by vacuum heat treatment.

[0043] The process steps are as follows:

[0044] (1) The raw material is Si with an average particle size of 0.5 microns 3 N 4 Powder 100g, Li 2 CO 3 1.63 grams of powder (equivalent to adding 0.66 grams of Li 2 O), Y 2 o 3 Powder 0.33 gram, with absolute ethanol as mixing medium, with agate ball as grinding ball, ball mill mixing 20 hours;

[0045] (2) Dry the mixed powder and pass through a 100-mesh sieve, and mold it under a pressure of 10MPa;

[0046] (3) The formed body is sintered at 1600°C in a nitrogen atmosphere of 0.2MPa and kept for 4 hours.

[0047] (4) Porous Si after sintering 3 N 4 The samples were heat-treated at 1500°C for 6 hours under vacuum conditions.

[0048] Porous Si prepared by this method 3 N 4 The ceramics are shown by X-ray diffraction patterns to be complete β-Si 3 N 4 . The porosity measu...

Embodiment 3

[0050] The difference from Example 1 is that only Li 2 O as a sintering aid.

[0051] The process steps are as follows:

[0052] (1) The raw material is Si with an average particle size of 0.5 microns 3 N 4 Powder 100g, Li 2 CO 3 2.47 grams of powder (equivalent to adding 1 gram of Li 2 O), using absolute ethanol as the mixing medium, using agate balls as the grinding balls, and ball milling and mixing for 20 hours;

[0053] (2) Dry the mixed powder and pass through a 100-mesh sieve, and mold it under a pressure of 10MPa;

[0054] (3) The formed body is sintered at 1600°C in a nitrogen atmosphere of 0.2MPa and held for 4 hours, then vacuumed to less than 1 atmosphere (relative vacuum is -0.02MPa), and then heated to 1800°C and held for 4 hours. Hour.

[0055] Porous Si prepared by this method 3 N 4 The X-ray diffraction pattern of ceramics shows that the tested material is complete β-Si 3 N 4 . The porosity measured by the Archimedes method is 56.1%. The Li conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com