Active polypeptide separated from anchovy

An active peptide and anchovy technology, applied in the field of peptide separation, can solve the problem of underutilization of resources and achieve the effects of increasing total antioxidant capacity, improving survival rate, and reducing nerve cell damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 anchovy hair yeast liquid

[0035]Grind the by-products of anchovy with a mincer, perform coarse filtration to remove impurities, and then heat at 80°C for 2 hours to obtain a viscous semi-solid state to obtain an anchovy concentrate; the anchovy concentrate is prepared according to (1:3, w / w ) ratio into water, mixed evenly, added flavor protease with 3% weight of anchovy concentrate, and enzymolyzed at 60° C. for 5 hours to obtain anchovy enzymatic hydrolyzate. Add 5% bran by weight of the enzymatic hydrolyzate to the obtained anchovy hydrolyzate, sterilize at 121°C for 20 minutes, insert Aspergillus oryzae, ferment at 30°C, and the fermentation period is 3 days. After the fermentation is finished, the obtained fermented liquid is filtered with gauze, and sterilized at 100°C for 20 minutes to obtain the finished anchovy fermented yeast liquid.

[0036] The physical and chemical indicators of anchovy fermented yeast liquid and enzymatic...

Embodiment 2

[0041] Embodiment 2 active peptide G-15 gel chromatography

[0042] Freeze the finished anchovy yeast liquid into dry powder with a freeze dryer, dissolve it in ultrapure water to make a solution with a concentration of 0.1g / mL, pass through a 0.45μm inorganic water membrane, and perform G-15 gel chromatography The column was used for separation, the sample volume was 1 mL, distilled water was used as the eluent, the flow rate was 1 mL / min, and the detection wavelength was 220 nm to collect the components with the highest anti-nerve cell damage activity.

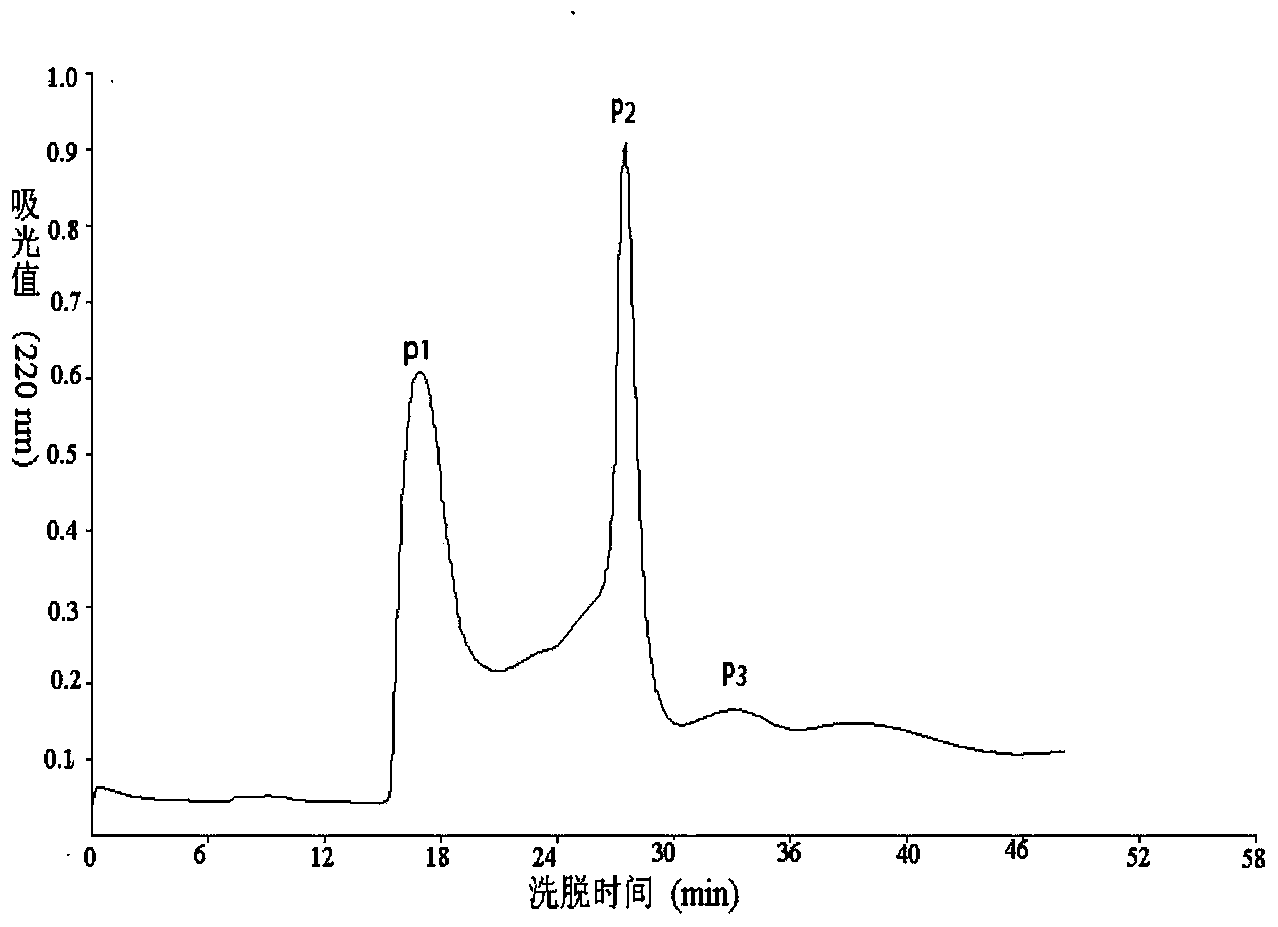

[0043] like figure 1 As shown, the sample is divided into three elution peaks after passing through the G-15 gel chromatography column, and the elution time is 16.5~18.5min respectively (P 1 peak), 27~30min(P 2 peak), 30~36min (P 3 Peak), the anti-neurocyte injury activity of the three peaks was determined, and it was found that P 2 The peak has the highest anti-nerve cell injury activity, and the collection of P 2 The ...

Embodiment 3

[0044] DEAE-Sepharose FF ion-exchange column chromatography of embodiment 3 active polypeptide

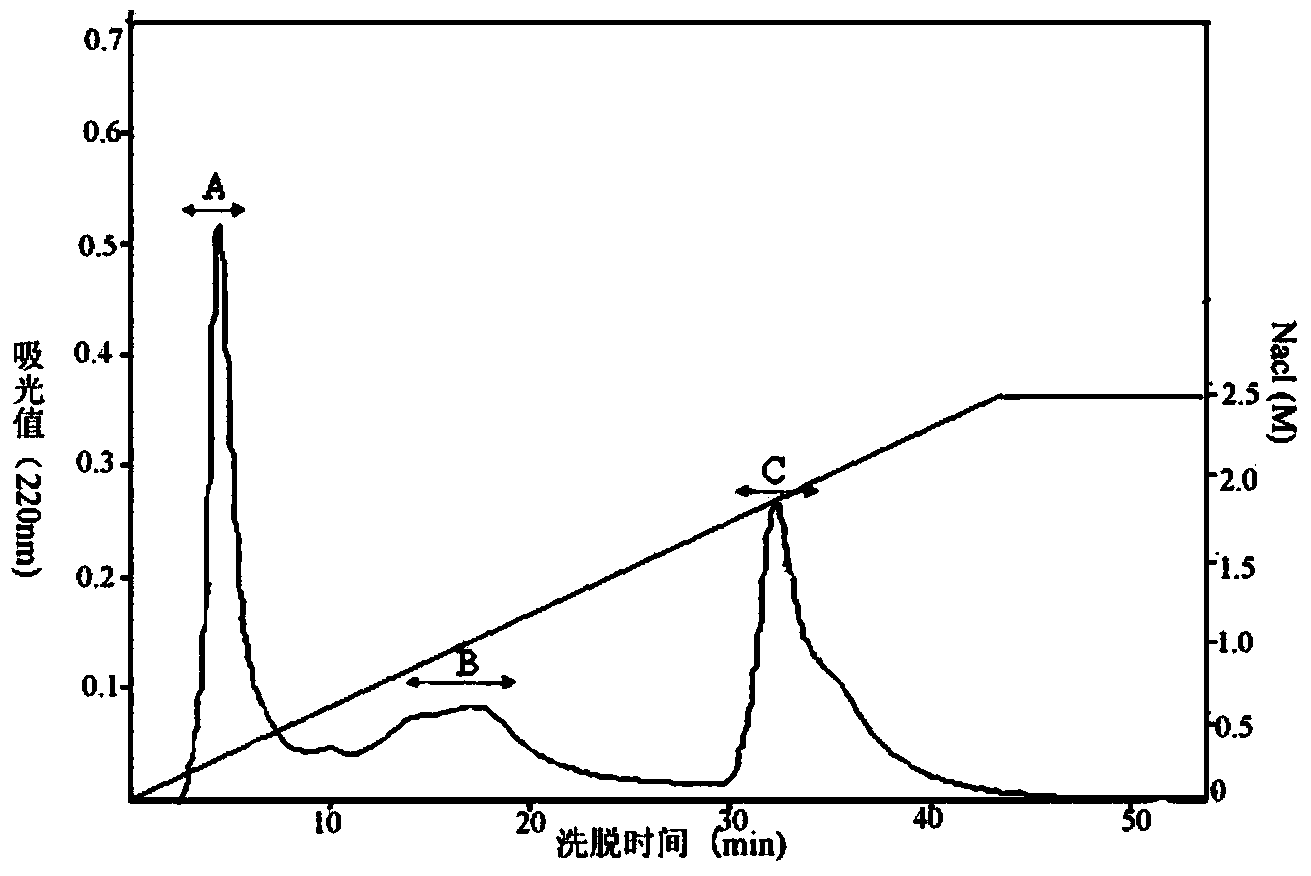

[0045] P 2 The peak was further separated and purified by DEAE-Sepharose FF ion-exchange column chromatography, and the DEAE-Sepharose FF ion-exchange column (18 × 80mm) equilibrated with 5mM Tris-HCl (pH8.5) buffer solution on the concentrated sample was used at a concentration of 0-2mol / L NaCl gradient elution, flow rate 1mL / min, detection wavelength 220nm, collect the components with the highest anti-nerve cell damage activity, dialyze with Tris-HCl solution, and freeze-dry. Active polypeptide DEAE-Sepharose FF ion exchange column chromatography results see figure 2 .

[0046] like figure 2 , P 2 After passing through DEAE-Sepharose FF, three elution peaks were formed, and the elution time was 3-6min (peak A), 13-20min (peak B), and 32-37min (peak C). The damage activity was measured, and it was found that peak A had the highest anti-nerve cell damage activity. A large am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com