Binder composition for electricity storage devices, slurry for electricity storage device electrodes, electricity storage device electrode, slurry for forming protective film, protective film, and electricity storage device

A technology for electrical storage devices and compositions, applied in non-aqueous electrolyte battery electrodes, battery electrodes, hybrid capacitor electrodes, etc., can solve the problems of damage to oxidation resistance of organic polymers, deterioration of charge and discharge characteristics, etc., and achieve discharge rate characteristics. Good effect, excellent liquid retention, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0179] In preparation of the slurry for electrical storage device electrodes (mixing operation of each component), it is preferable to perform at least a part of the process under reduced pressure. Thereby, generation of air bubbles in the obtained electrode layer can be prevented. As the degree of decompression, as an absolute pressure, it is preferably set to 5.0×10 3 ~5.0×10 5 Pa or so.

[0180] As mixing and stirring for producing the slurry for electrical storage device electrodes, it is necessary to select a mixer capable of stirring to such an extent that no aggregates of the active material remain in the slurry, and necessary and sufficient dispersion conditions. The degree of dispersion can be measured by a fineness meter, but it is preferable to mix and disperse in such a way as to eliminate at least aggregates larger than 100 μm. As a mixer suitable for such conditions, a ball mill, a sand mill, a pigment disperser, a crushing machine, an ultrasonic disperser, a ...

Embodiment 1

[0264] 7.1.1. Preparation of adhesive composition for electrical storage devices

[0265] The interior of an autoclave with an internal volume of about 6 L equipped with an electromagnetic stirrer is fully replaced with nitrogen, then 2.5 L of deoxidized pure water and 25 g of ammonium perfluorodecanoate as an emulsifier are added, and the temperature is raised while stirring at 350 rpm to 60°C. Next, a mixed gas containing 70% of vinylidene fluoride (VDF) and 30% of hexafluoropropylene (HFP) as monomers was fed until the internal pressure reached 20 kg / cm 2 . 25 g of a FLON-113 solution containing 20% of diisopropylperoxydicarbonate as a polymerization initiator was pressurized using nitrogen gas to initiate polymerization. During the polymerization, the internal pressure was maintained at 20kg / cm according to 2 Press the mixed gas containing VDF60.2% and HFP39.8% successively to maintain the pressure at 20kg / cm 2 . In addition, since the polymerization rate decreased ...

Embodiment 2

[0293] 7.2. Embodiment 2 and Comparative Example 3

[0294] 7.2.1. Preparation of adhesive composition for electrical storage devices

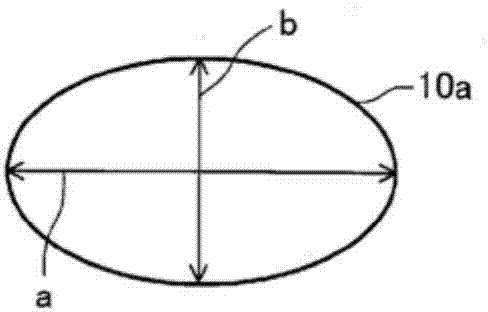

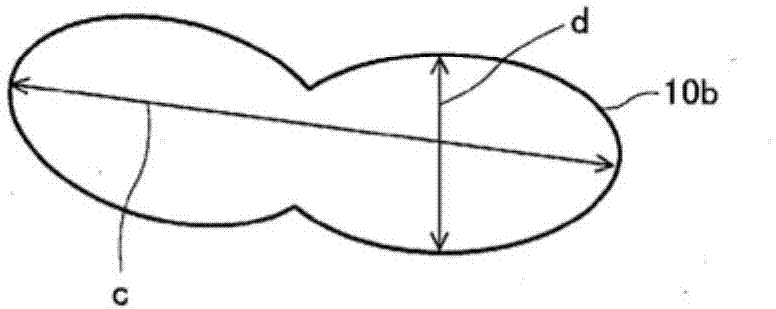

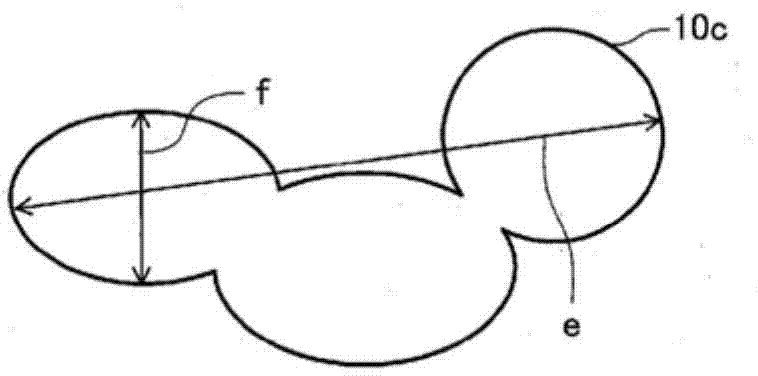

[0295] In the "7.1.1. Preparation of binder composition for electrical storage devices" of the above-mentioned Example 1, the composition of the monomer and the amount of emulsifier were appropriately changed, and the same operation was performed as in Example 1 to prepare the Aqueous dispersion of polymer particles having a composition of , and water was removed or added under reduced pressure according to the solid content concentration of the aqueous dispersion to obtain an aqueous dispersion with a solid content concentration of 40%. About the obtained polymer particle, it carried out similarly to Example 1, and performed the measurement of the number average particle diameter, the calculation result of the ratio of a major diameter and a minor diameter, and DSC measurement. The results are shown in Table 1 together.

[0296] 7.2.2. Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com