Lithium ion battery positive electrode material composed of cerium oxide and carbon co-coated lithium vanadium phosphate and preparation method thereof

A carbon-coated technology for lithium vanadium phosphate and lithium ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor high-rate charge and discharge performance, and achieve the effects of reducing corrosion, simple process, and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

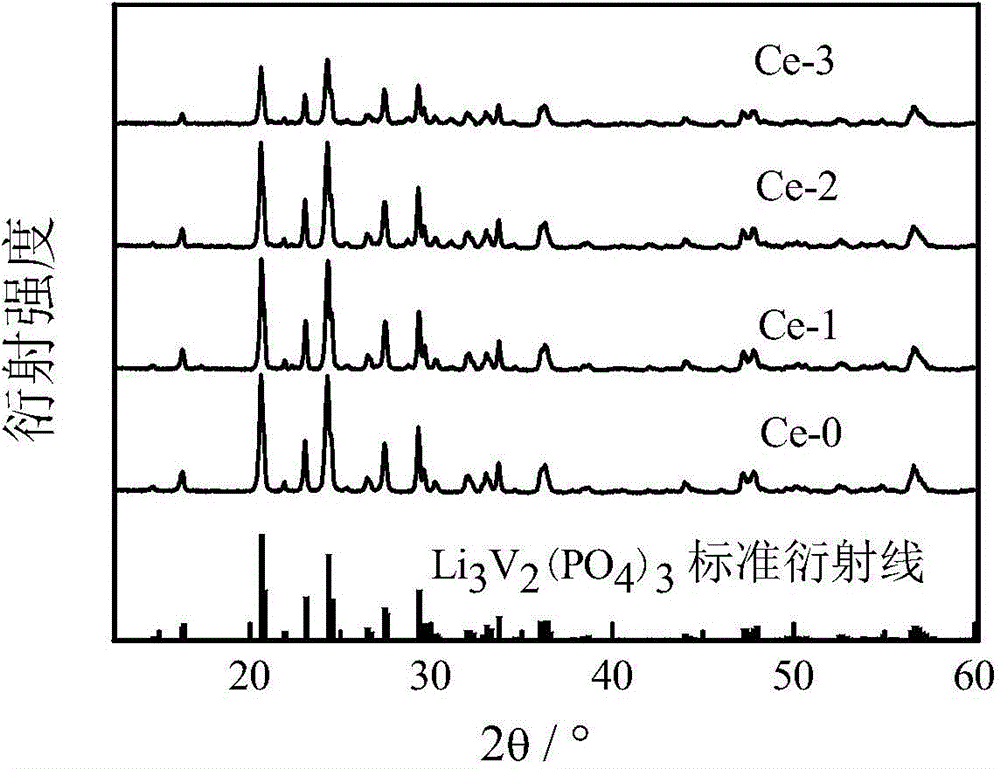

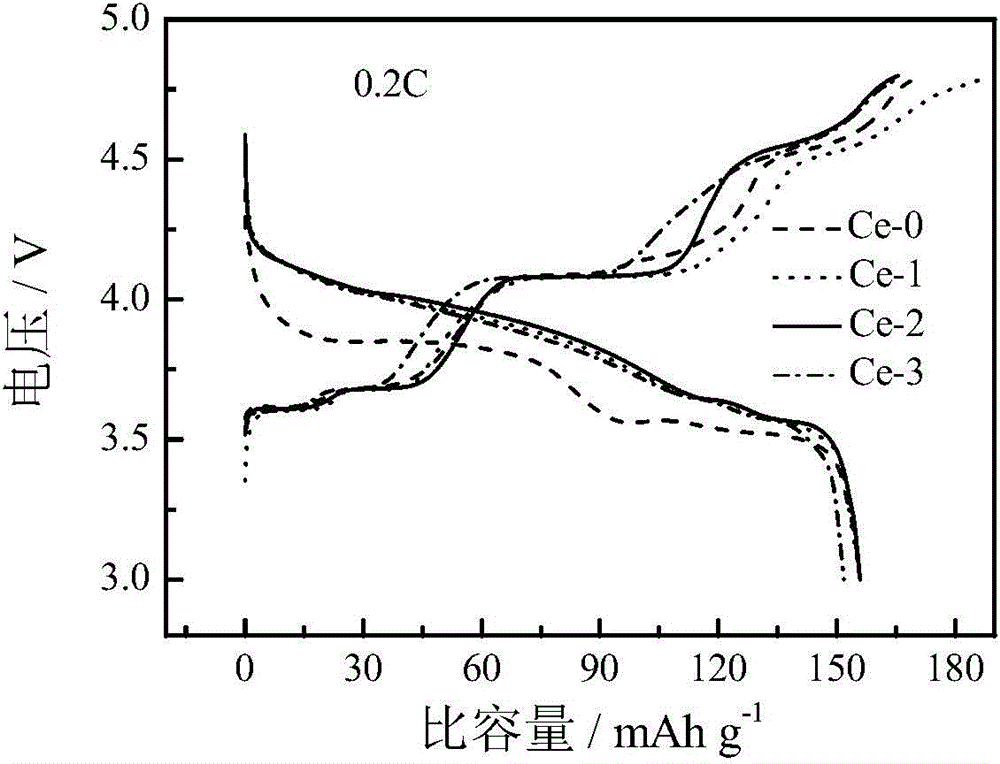

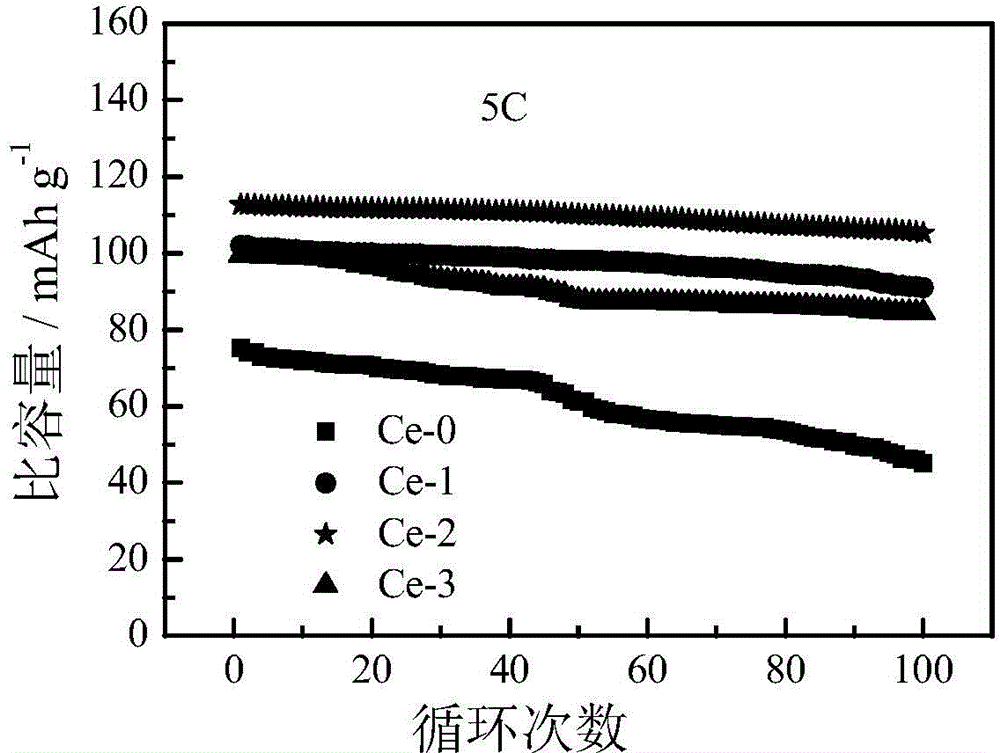

Embodiment 1

[0037] Dissolve 4.145g of citric acid in 20mL of deionized water, pour it into a beaker containing 1.803g of vanadium pentoxide, and stir on a magnetic heating stirrer at a constant temperature of 60°C for 30 minutes to form a dark blue solution. Dissolve 3.421 g of ammonium dihydrogen phosphate and 1.121 g of lithium carbonate in 20 mL of deionized water respectively, add them to the above dark blue solution, and stir on a magnetic heating stirrer at a constant temperature of 60°C for 30 minutes. The pH value was adjusted to 4 with acetic acid, and the mixed liquid was stirred at a constant temperature of 60° C. for 1 hour on a magnetic heating stirrer. Raise the temperature to 80°C, continue stirring to evaporate the solvent to form a dark blue wet gel, and put it in an oven at 80°C for 1 day to form a dry gel. The xerogel was ground in a mortar for 30 minutes to form a blue-green powder. Then the blue-green powder is kept at 350° C. for 4 hours under a hydrogen-nitrogen mi...

Embodiment 2

[0041]Dissolve 4.145g of citric acid in 20mL of deionized water, pour it into a beaker containing 1.803g of vanadium pentoxide, and stir on a magnetic heating stirrer at a constant temperature of 60°C for 30 minutes to form a dark blue solution. Dissolve 3.421 g of ammonium dihydrogen phosphate and 1.121 g of lithium carbonate in 20 mL of deionized water respectively, add them to the above dark blue solution, and stir on a magnetic heating stirrer at a constant temperature of 60°C for 30 minutes. The pH value was adjusted to 4 with acetic acid, and the mixed liquid was stirred at a constant temperature of 60° C. for 1 hour on a magnetic heating stirrer. Raise the temperature to 80°C, continue stirring to evaporate the solvent to form a dark blue wet gel, and put it in an oven at 80°C for 1 day to form a dry gel. The xerogel was ground in a mortar for 30 minutes to form a blue-green powder. Then the blue-green powder is kept at 350° C. for 4 hours under a hydrogen-nitrogen mix...

Embodiment 3

[0045] Dissolve 4.145g of citric acid in 20mL of deionized water, pour it into a beaker containing 1.803g of vanadium pentoxide, and stir on a magnetic heating stirrer at a constant temperature of 60°C for 30 minutes to form a dark blue solution. Dissolve 3.421 g of ammonium dihydrogen phosphate and 1.121 g of lithium carbonate in 20 mL of deionized water respectively, add them to the above dark blue solution, and stir on a magnetic heating stirrer at a constant temperature of 60°C for 30 minutes. The pH value was adjusted to 4 with acetic acid, and the mixed liquid was stirred at a constant temperature of 60° C. for 1 hour on a magnetic heating stirrer. Raise the temperature to 80°C, continue stirring to evaporate the solvent to form a dark blue wet gel, and put it in an oven at 80°C for 1 day to form a dry gel. The xerogel was ground in a mortar for 30 minutes to form a blue-green powder. Then the blue-green powder is kept at 350° C. for 4 hours under a hydrogen-nitrogen mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com