Preparation method of yttrium silicate ceramic powder

A technology of ceramic powder and yttrium silicate, which is applied in the field of preparation of oxide ceramic materials, can solve the problem that it is difficult to obtain products with a single crystal form, and achieve the effect of stable pH value, high purity, and guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

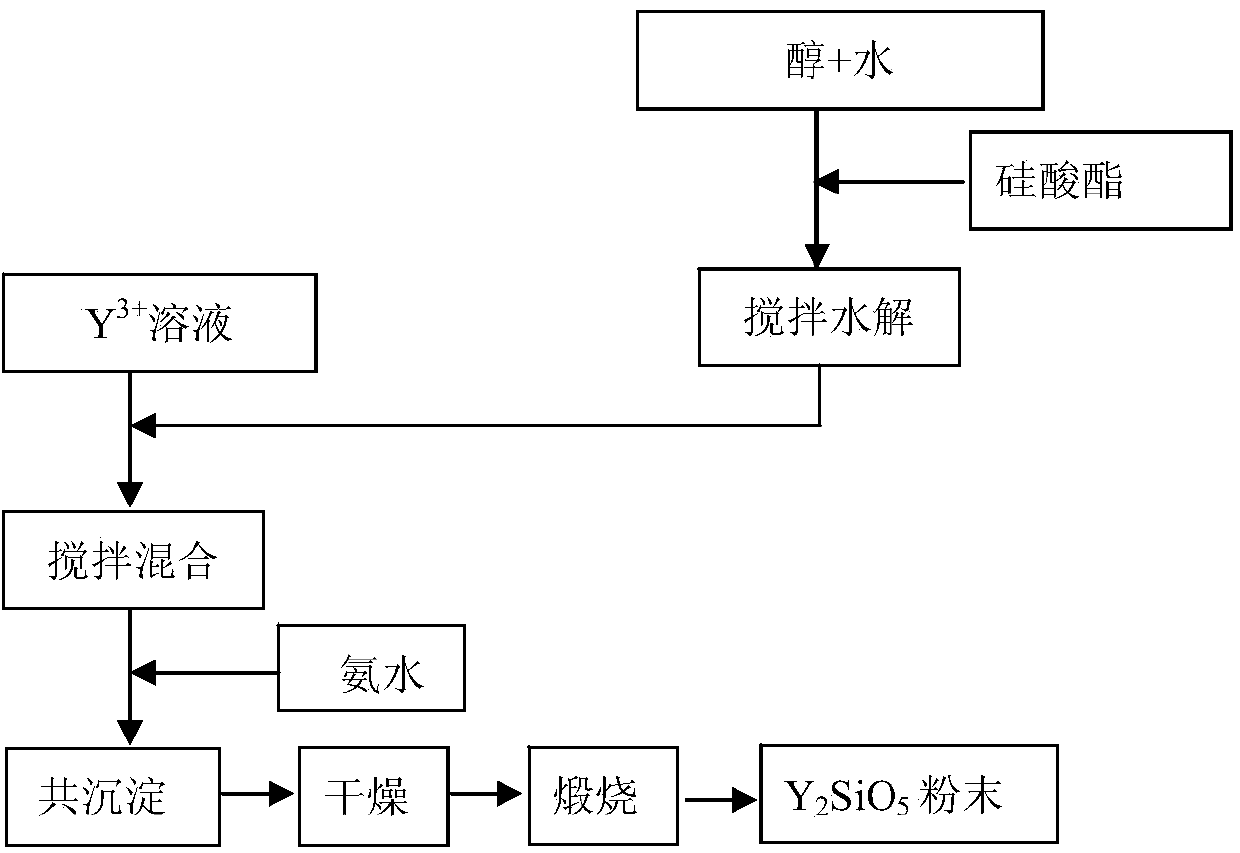

Method used

Image

Examples

Embodiment 1

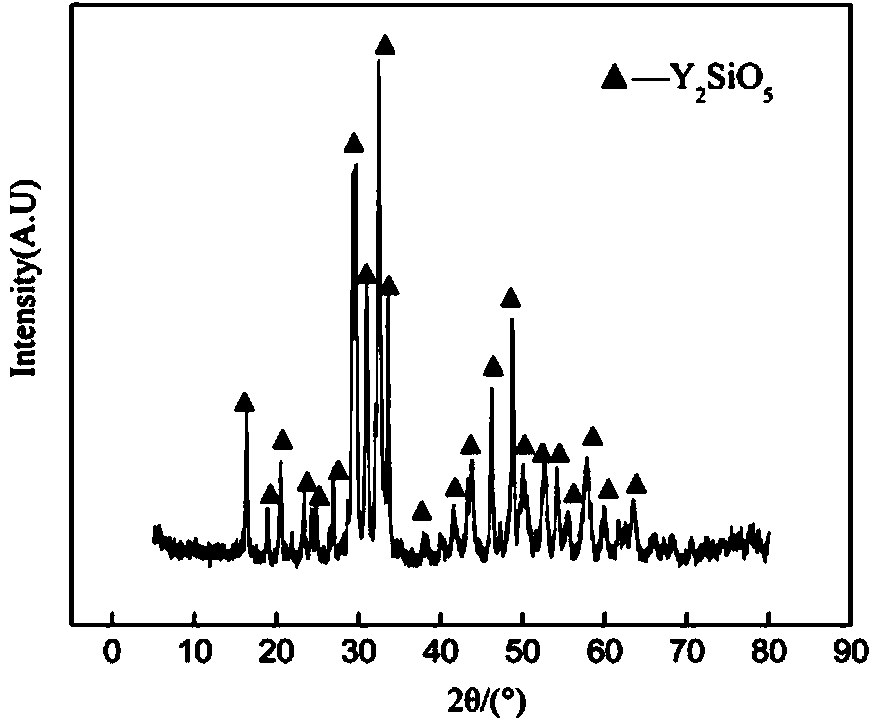

[0051] Take the preparation of 10 kg of yttrium silicate ceramic powder as an example. Weigh 7.9 kg Y 2 o 3 Dissolve in excess nitric acid, add deionized water to prepare 1mol / LY(NO 3 ) 3 Clear solution. According to Y 2 SiO 5 Medium SiO 2 % by weight, converted to tetraethyl orthosilicate TEOS ((C 2 h 5 ) 4 SiO 4 ) is 8.1L, the density of tetraethyl orthosilicate is 0.929g / ml, SiO 2 The content is 28%. Measure 8.1L tetraethyl orthosilicate, mix with 8.1L absolute ethanol (ErOH) and 36.4L deionized water (H 2 O) mix, and prepare tetraethyl orthosilicate prehydrolyzate. 1mol / LY(NO 3 ) 3 solution and TEOS:ErOH:H 2 O = 1:1:4 pre-hydrolyzate mix. Take 50L of distilled water and adjust its pH to 9-10 with concentrated ammonia water. Slowly add the above mixed solution into ammonia water with a pH value of 9-10 to carry out chemical co-precipitation reaction, adjust the reaction system with 2-fold diluted ammonia water to keep the pH value at 9-10. During this rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com