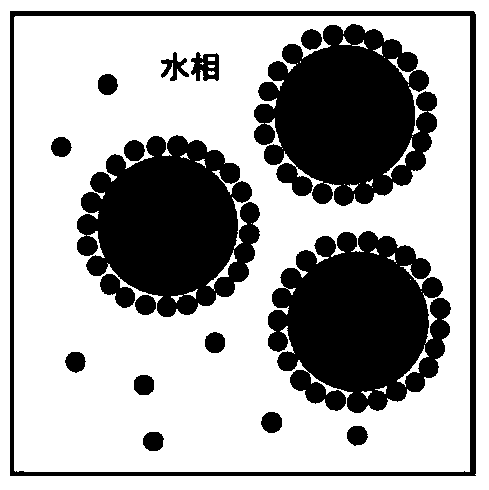

Oil-in-water emulsion free of surfactant and use thereof

An oil-in-water emulsion and surfactant technology, applied in the field of biomedicine, can solve the problems of no vaccine preparation design optimization, no Pickering emulsion, and the emulsion cannot be applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Embodiment 1: Adopt polyPLGA particle to prepare oil-in-water emulsion

[0106] Preparation of PLGA particles by nanoprecipitation method:

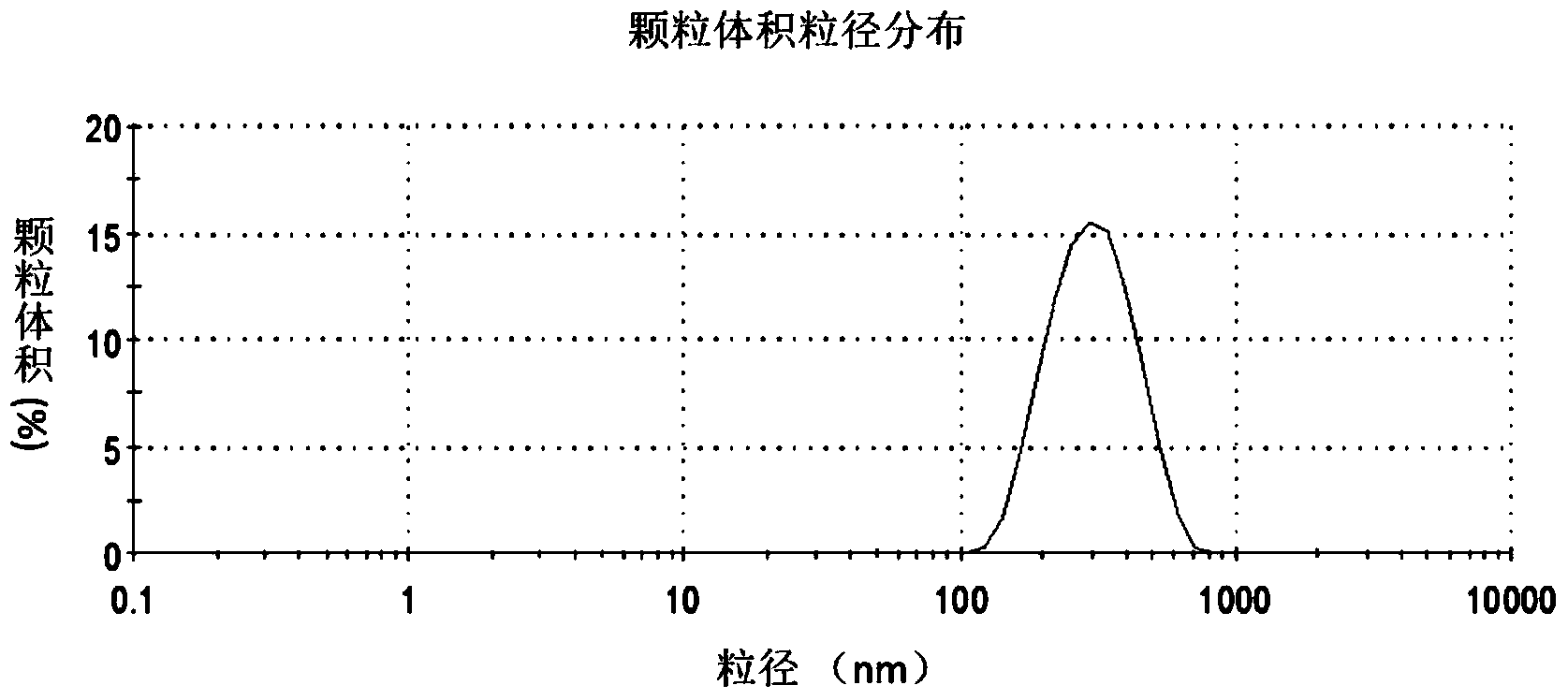

[0107] Accurately weigh 0.30 g of PLGA (LA:GA is 50:50, molecular weight is 110,000 Daltons) using an electronic balance, dissolve it in 1 mL of acetone, and drop the solution at a rate of 1 drop per second with a No. 9 needle. Add it to 20mL aqueous solution (containing 1wt.% PVA (alcoholysis degree: 99%, viscosity: 5.0mPa·s), magnetic stirring, rotating speed: 500rpm), stir overnight at 25°C, centrifuge at 20000g for 20min, discard the upper Clear, add 5 mL of deionized water to the precipitate, ultrasonically disperse, centrifuge at 20,000 g for 5 min, discard the supernatant, freeze-dry the precipitate to obtain PLGA particles, and store in the refrigerator at 4 °C. The average particle diameter of the prepared PLGA particles is 226nm, and the span is 0.535. The surface of the prepared particles was observed by scanning elect...

Embodiment 2

[0115] Embodiment 2: adopt aluminum hydroxide particle to prepare oil-in-water emulsion

[0116] Prepare aluminum hydroxide particles by microemulsion method:

[0117] Triton X-100, n-butanol and cyclohexane were mixed at a volume ratio of 1:0.5:20 and magnetically stirred (800 rpm, 5 min) to obtain an oil phase. Add 1mol / L AlCl dropwise to the oil phase (20mL) under magnetic stirring (500rpm) at a rate of 2mL / min using a syringe propulsion pump 3 solution (2 mL) to obtain an inverse microemulsion of aluminum chloride. Use a syringe propulsion pump to drip ammonia water into the above-mentioned inverse microemulsion at a rate of 0.5mL / min to keep the pH value of the reaction system higher than 10.0. After reacting for 2h, add 10mL of acetone to break the emulsion, and centrifuge (15000g, 5min ), discard the supernatant, wash repeatedly with absolute ethanol three times, and deionized water once, and finally freeze-dry to obtain aluminum hydroxide particles, which are stored ...

Embodiment 3

[0120] Embodiment 3: adopt calcium phosphate particle to prepare oil-in-water emulsion

[0121] Preparation of hollow calcium phosphate particles by template method:

[0122] After mixing and stirring 3.0g Tween80, 0.25g PEG6000, 3.0mL0.5mol / L Tris-HCl (pH8.0) and 1.5mL deionized water, ultrasonic 20min (10W) to form non-ionic surfactant vesicles, drop into 3.55mLCaCl 2 (0.175mol / L) solution, after stirring for 0.5h, add 3.55mL Na 2 HPO 4 (0.175mol / L) solution can obtain the suspension of sodium phosphate particle, add 0.83mL MgCl 2 solution (0.075mmol / L) to stabilize the newly formed calcium phosphate particles, continue to stir for 2h, centrifuge and wash, and vacuum dry to obtain hollow calcium phosphate particles. The average particle diameter of the particles is 210nm, the thickness of the shell layer is 30-40nm, and the Span of the particles is 0.349. The prepared particles are hollow spheres.

[0123] Preparation of oil-in-water emulsion:

[0124] Accurately weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com