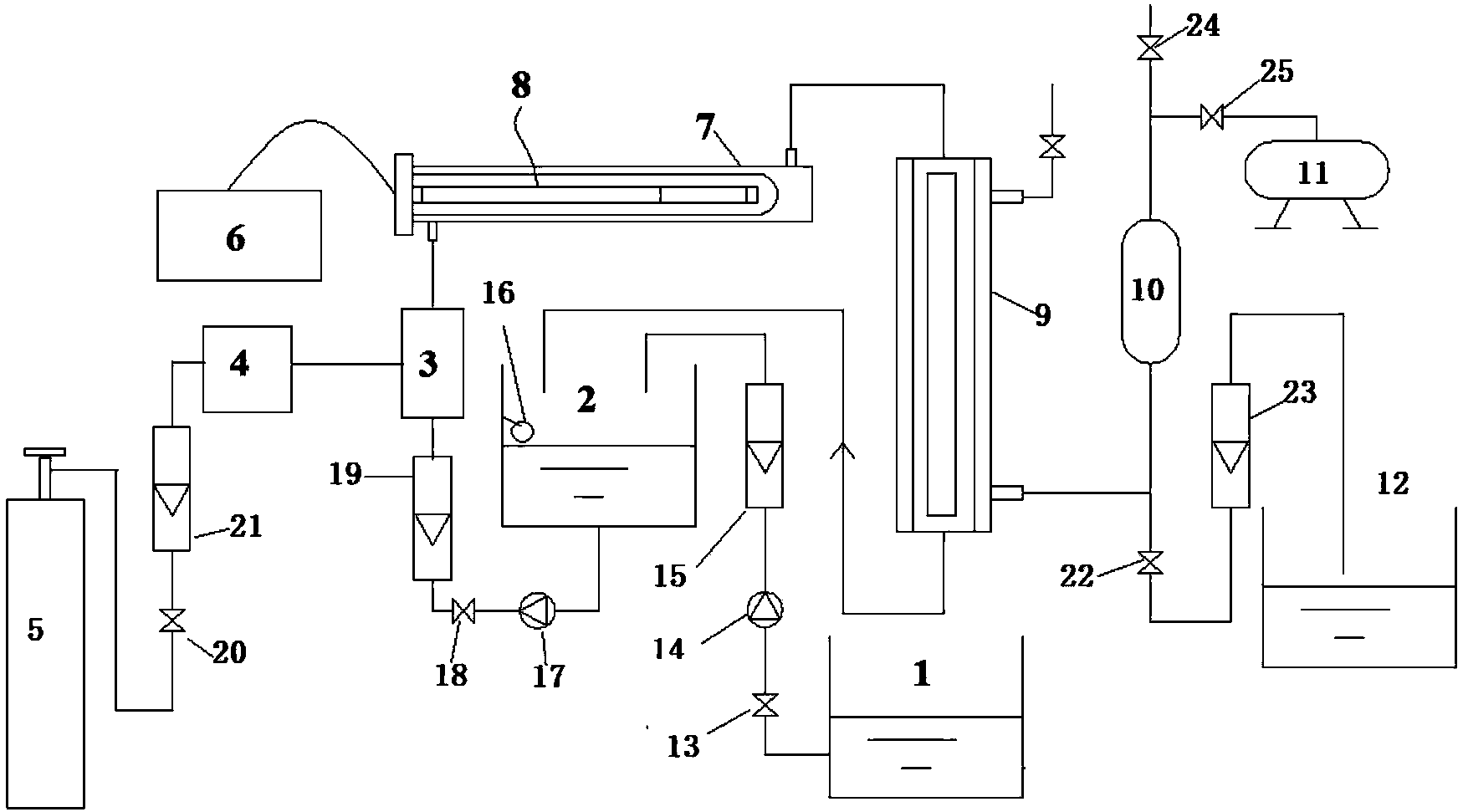

Ozone / photocatalysis oxidation-membrane separation integrated method and integrated set for advanced wastewater treatment

A photocatalytic oxidation and advanced treatment technology, applied in the field of water treatment, can solve the problems of low membrane flux, poor oxidation resistance, and low oxidant utilization efficiency, so as to alleviate membrane fouling, prolong membrane replacement cycle, and improve photocatalytic efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The above-mentioned ozone / photocatalytic oxidation-membrane separation integrated device is used to treat wastewater containing acrylonitrile, the conditions are as follows: raw water COD=150mg / L, pH=7.5, catalyst is nano-TiO 2 , the amount of catalyst added is 1.5g / L wastewater, the power of the ultraviolet lamp is 25W, the outer diameter of the lamp tube is 24mm, the total length of the lamp tube is 900mm, the length of the 185nm band is 600mm, the length of the 254nm band is 300mm, and the oxygen flow rate is 1L / min. In the ozone / oxygen gas mixture entering the gas-liquid mixer, the ozone concentration is 46mg / L. Tubular ceramic membrane is used in the ceramic membrane filter, the average pore size of the ceramic membrane is 0.5μm, the transmembrane pressure difference is 0.2MPa, the air backwash pressure is 0.5MPa, the backwash cycle is 5min, the backwash time is 10s, and the exhaust time for 5s. Applying the device involved in the present invention to treat acrylo...

Embodiment 2

[0041] The above-mentioned ozone / photocatalytic oxidation-membrane separation integrated device is used to treat coking wastewater, the conditions are as follows: raw water COD=124mg / L, pH=7.8, catalyst is nano-TiO 2 , the amount of catalyst added is 0.5g / L wastewater, the power of the ultraviolet lamp is 25W, the outer diameter of the lamp tube is 24mm, the total length of the lamp tube is 900mm, the length of the 185nm band is 450mm, the length of the 254nm band is 450mm, and the oxygen flow rate is 1L / min. In the ozone / oxygen gas mixture entering the gas-liquid mixer, the ozone concentration is 1mg / L. A tubular ceramic membrane is used in the ceramic membrane filter. The average pore size of the ceramic membrane is 0.02μm, the transmembrane pressure difference is 0.3MPa, the air backwash pressure is 0.5MPa, the backwash cycle is 5min, the backwash time is 10s, and the exhaust The time is 5s. Applying the device involved in the present invention to treat coking wastewater, ...

Embodiment 3

[0043] The above-mentioned ozone / photocatalytic oxidation-membrane separation integrated device is used to treat papermaking wastewater, the conditions are as follows: raw water COD=160mg / L, pH=7.6, catalyst is nano-TiO 2 , the addition amount is 1.5g / L waste water, the power of the ultraviolet lamp is 25W, the outer diameter of the lamp tube is 24mm, the total length of the lamp tube is 900mm, the length of the 185nm band is 300mm, the length of the 254nm band is 600mm, the oxygen flow rate is 1L / min, enter In the ozone / oxygen gas mixture of the gas-liquid mixer, the ozone concentration is 46mg / L; hydrogen peroxide is added to the water inlet tank, and the amount of hydrogen peroxide added is 0.01mol / L waste water. The flat ceramic membrane is used in the ceramic membrane filter. The average pore size of the ceramic membrane is 0.5μm, the transmembrane pressure difference is 0.15MPa, the air backwash pressure is 0.5MPa, the backwash cycle is 10min, the backwash time is 15s, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com