A kind of preparation technology of chitin colloid

A preparation technology, chitin technology, applied in the field of chitin colloid preparation technology, can solve the problems of waste of water resources, waste of raw materials, waste of demand, etc., to save electric energy and water resources, small and loose colloidal particles, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

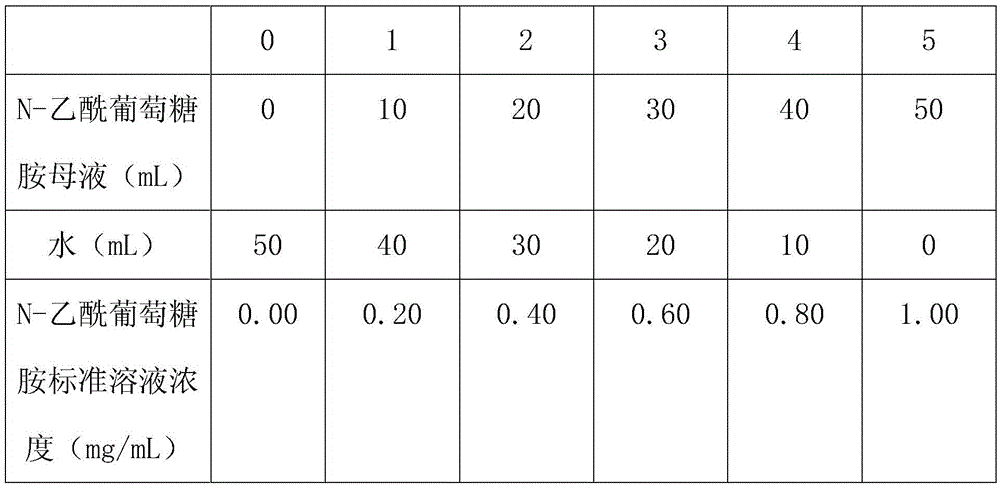

[0023] The preparation of N-acetylglucosamine standard solution and the assay method of standard curve are as follows:

[0024] Accurately weigh 1.0000g of N-acetylglucosamine (pre-dried at 70°C to balance weight), and dilute to 1L with deionized water to obtain N-acetylglucosamine mother liquor with a concentration of 1mg / ml.

[0025] Join as follows:

[0026] N-acetylglucosamine standard curve determination formula

[0027]

[0028] Determination method of standard curve

[0029] Take 1mL of N-acetylglucosamine standard solution No. 0, 1, 2, 3, 4, and 5, 1.5mL of DNS solution (standard of the Ministry of Agriculture) and a colorimetric tube, bathe in boiling water for 8min, set the volume of the colorimetric tube to 25mL, shake The absorbance was measured at 540nm with a UV spectrophotometer. Make a standard curve according to the amount and absorbance of N-acetylglucosamine.

Embodiment 1

[0031] (1), weigh chitin solid and pass through a 100-mesh sieve, and dry to obtain chitin powder;

[0032] (2) Dissolve 1.0000g of chitin powder in 20mL of supersaturated citric acid, heat to 40°C, stir and dissolve with a magnetic stirrer for 12 hours, at 40°C, 250W ultrasonic power for 30 minutes, and then at 40°C Magnetic stirring for 24 hours;

[0033] (3) Slowly add 2mol / L sodium hydroxide solution dropwise to the chitinic acid solution under ultrasonic conditions of 250W power under ultrasonic at 10°C, adjust the pH value to 5.5, and become a colloidal liquid, and continue ultrasonic vibration for 30 Minutes, then stirred at room temperature with a magnetic stirrer for 12 hours.

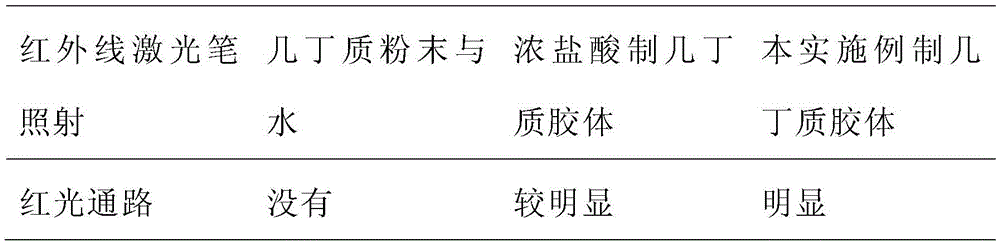

[0034] Add distilled water or deionized water, and prepare chitin colloid with a concentration of 1.0000% in a 100ml volumetric flask. Fine-tune the pH to 6.0 with a small amount of strong acid or base. Finally, an infrared laser pointer is used to detect whether there is an obvious straigh...

Embodiment 2

[0041] (1), weigh chitin solid and pass through a 100-mesh sieve, and dry to obtain chitin powder;

[0042] (2) Dissolve 1.0000g of chitin powder in 30mL of supersaturated citric acid, heat to 40°C, stir and dissolve with a magnetic stirrer for 12 hours, at 40°C, 250W ultrasonic power for 30 minutes, and then at 40°C Magnetic stirring for 24 hours;

[0043] (3) Slowly add 2mol / L sodium hydroxide solution dropwise to the chitinic acid solution under ultrasonic conditions of 250W power under ultrasonic at 10°C, adjust the pH value to 5.5, and become a colloidal liquid, and continue ultrasonic vibration for 30 Minutes, then stirred at room temperature with a magnetic stirrer for 12 hours.

[0044]Add distilled water or deionized water, and prepare chitin colloid with a concentration of 1.0000% in a 100ml volumetric flask. Use a small amount of strong acid or strong base to fine-tune the pH to 6.0, and finally use an infrared laser pointer to check whether there is an obvious re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com