Method for implanting functional biological coating on surface of implant

A bio-coating, implant technology, applied in surface reaction electrolytic coating, coating, prosthesis and other directions, can solve the problems of long time consumption, complicated operation, unsatisfactory slow release effect, etc., and achieve rapid process and cheap raw materials. , the effect of facilitating large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Applied to bone implant materials

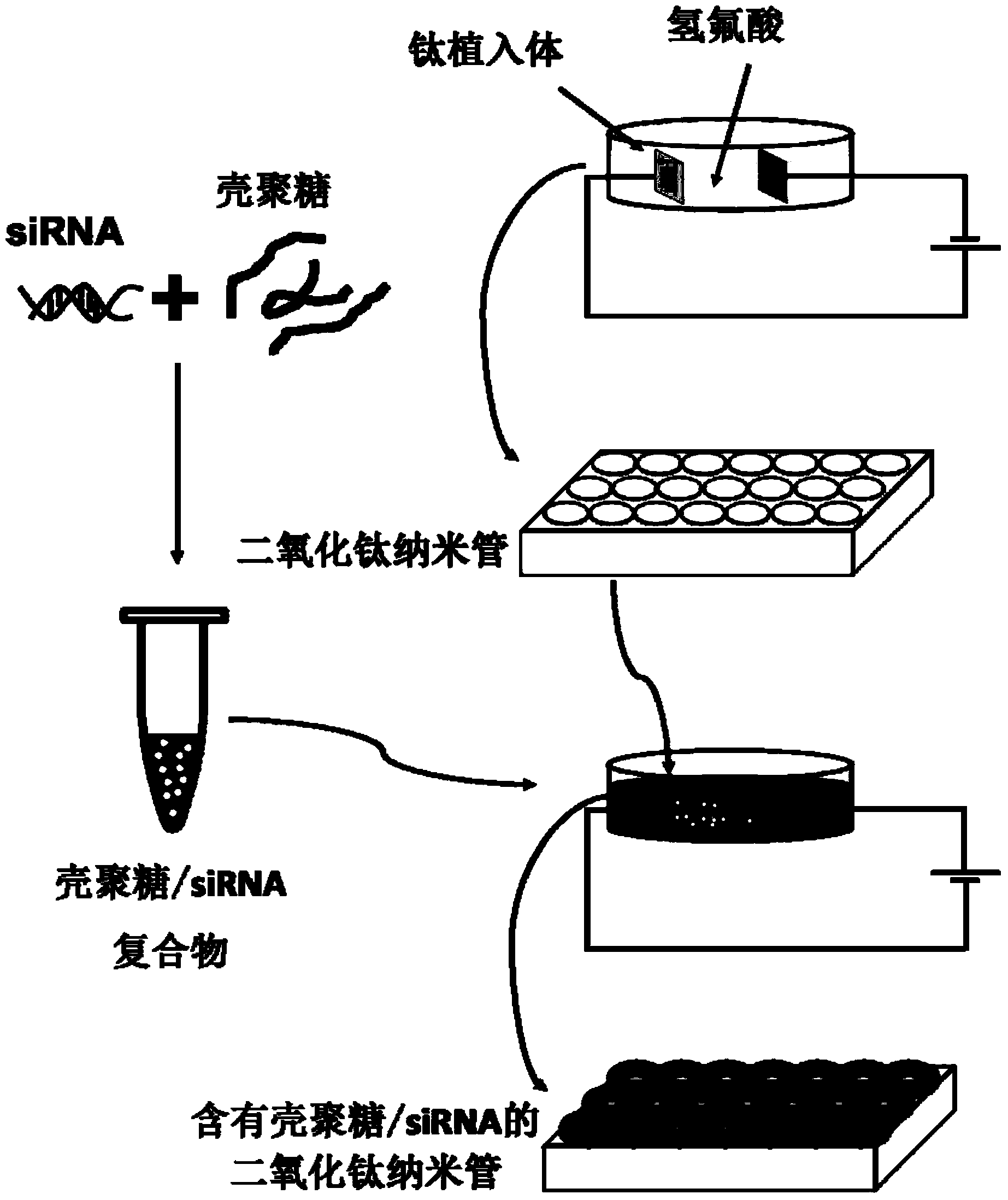

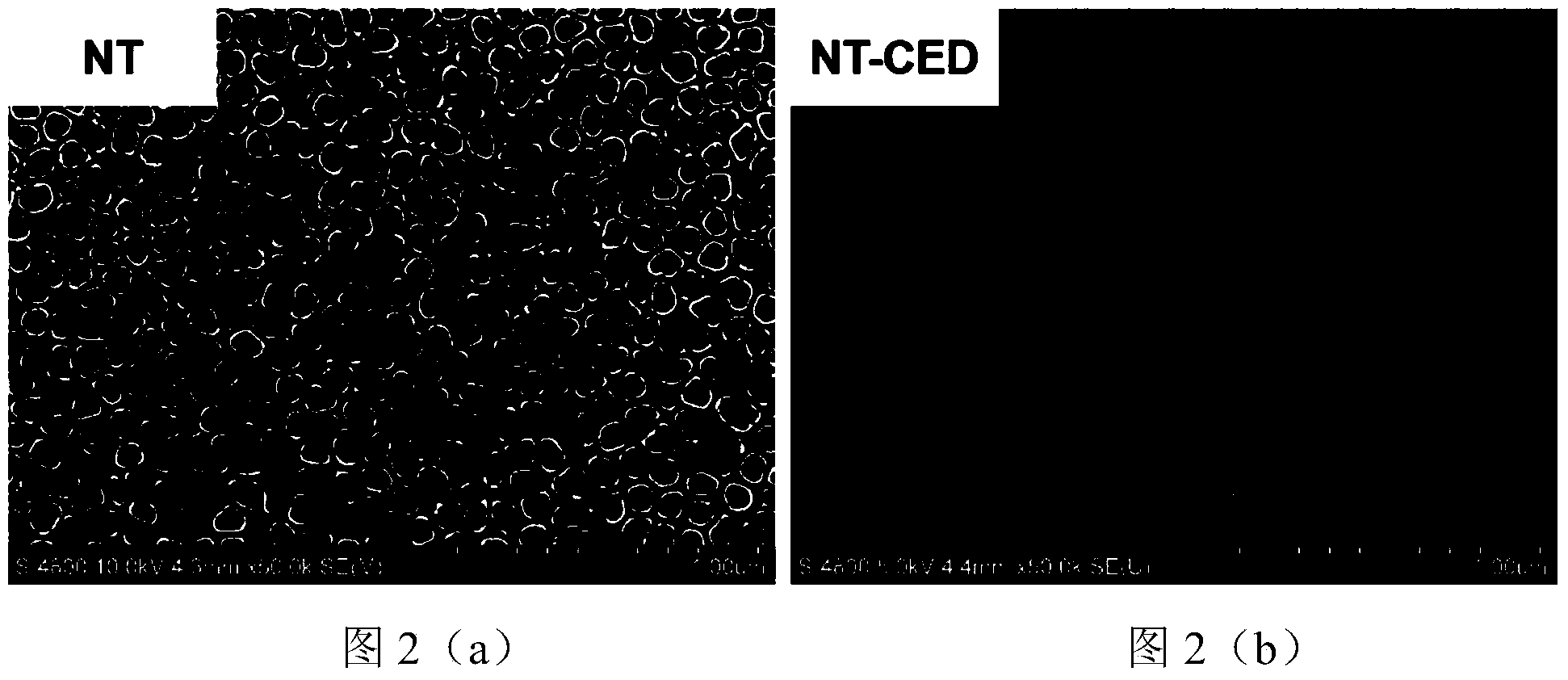

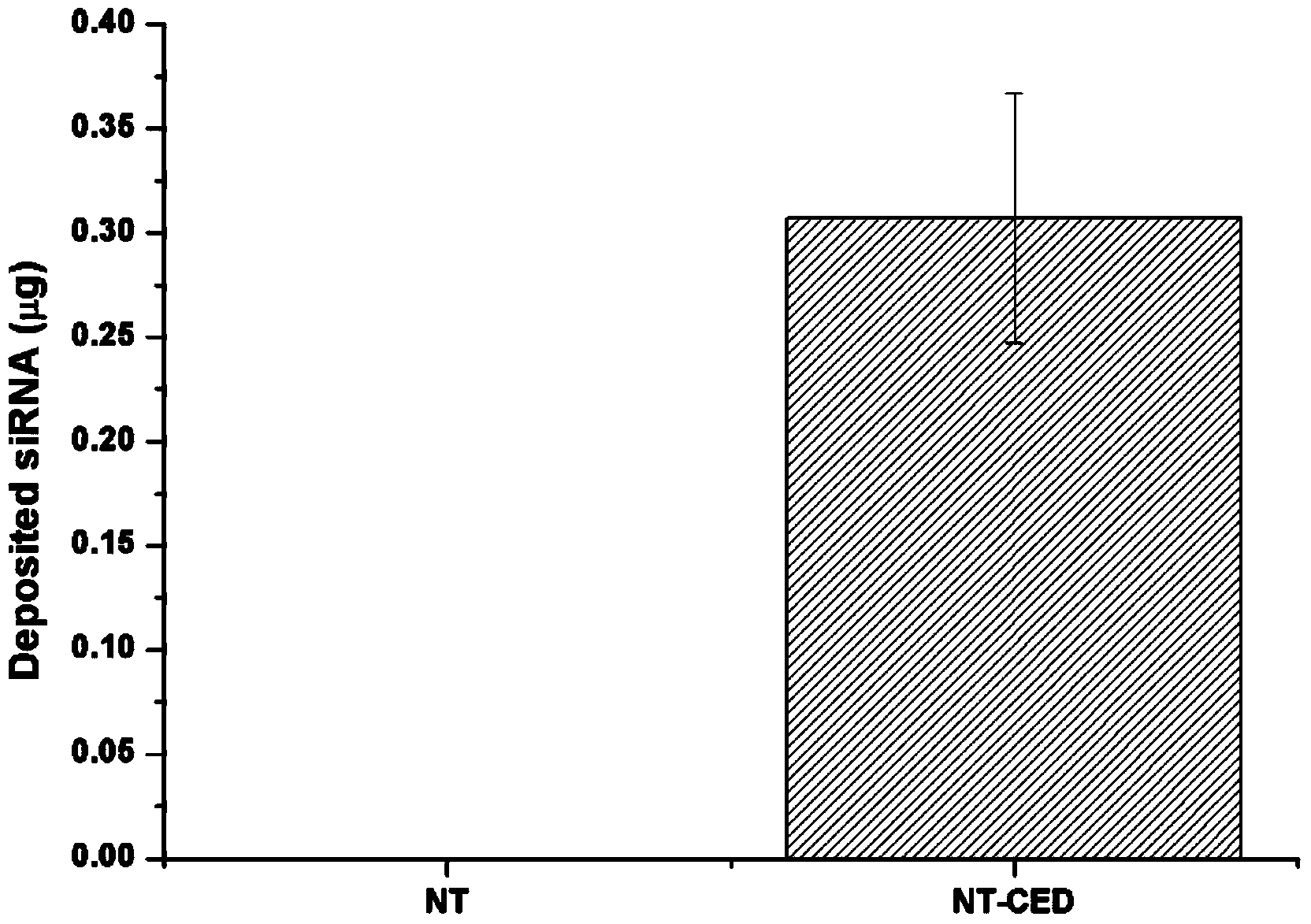

[0035] The siRNA in this example is: siRNA against Ckip-1 designed and synthesized by Shanghai Gemma Co., Ltd. according to the needs of osteogenesis, named siCkip-1. refer to figure 1 As shown, the method steps are as follows:

[0036] (1) Select pure titanium material provided by Northwest Institute of Nonferrous Metals to process bone implants;

[0037] (2) After the surface is polished, use acetone, absolute ethanol and deionized water to ultrasonically clean for 30 minutes, and dry it for use;

[0038] (3) prepare anodic oxidation electrolyte: deionized water is solvent, HF wt0.5% (mass percentage);

[0039] (4) Preparation of titanium dioxide nanotubes by anodic oxidation method: the titanium implant is used as the anode, and the platinum sheet or graphite is used as the cathode, which is put into the electrolyte prepared in the previous step. 1 hour, the distance between the two stages is 5mm, and the reaction...

Embodiment 2

[0052] Embodiment 2: Applied to cardiovascular stent

[0053] The siRNA used in this example is: according to the need for promoting the function of endothelial cells, Shanghai Gemma Company designed and synthesized siRNA against sFlt-1, named siFlt-1.

[0054] (1) Select pure titanium materials provided by Northwest Institute of Nonferrous Metals to process into cardiovascular stents;

[0055] (2) After the surface is polished, use acetone, absolute ethanol and deionized water to ultrasonically clean for 30 minutes, and dry it for use;

[0056] (3) prepare anodic oxidation electrolyte: deionized water is solvent, HF wt0.5% (mass percentage);

[0057] (4) Preparation of titanium dioxide nanotubes by anodic oxidation method: titanium vascular stent is used as anode, platinum sheet or graphite is used as cathode, and put into the electrolyte prepared in the previous step. The specific anodic oxidation parameters are: DC voltage 5-20V, power-on time For 0.5 hours, the two-stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com