Artificial antibody type titanium dioxide (TiO2)/ boron-doped diamond (BDD) membrane electrode and preparation method thereof

A technology of boron-doped diamond and titanium dioxide, which is applied in the field of artificial antibody-type titanium dioxide/boron-doped diamond film electrode and its preparation, can solve the problems of difficult recycling and low quantum yield, and achieve long-lasting recognition ability, high adsorption capacity, excellent The effect of photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

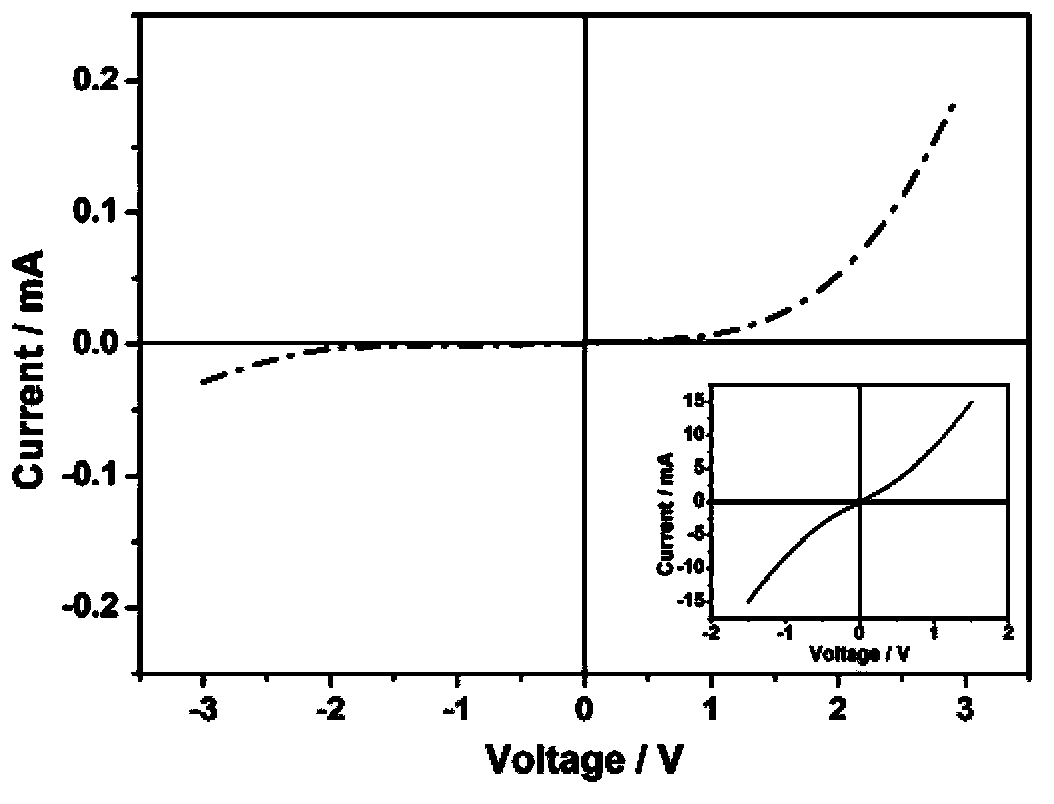

[0039] Immerse BDD in aqua regia and boil for 10min to completely remove the organic and inorganic stains on the surface, then place it in 2M1M H 2 SO 4 In the electrolyte, a bias voltage of +3 V was applied for 10 min to obtain a hydrophilic BDD surface with -OH terminals, and finally ultrasonically cleaned with ethanol and purified water, respectively. Prepare 25mL containing 0.03M TiOSO 4 and 3M H 2 SO 4 Then add 6mL concentrated hydrochloric acid and 10mg target pollutant (bisphenol A), stir vigorously at room temperature for 6h to completely dissolve, and finally adjust the pH of the mixed solution to 1.3 with ammonia water to obtain a precursor solution. Put the pre-treated BDD (10×45mm) electrode into a 100mL round bottom flask, pour the prepared precursor solution, soak the BDD electrode in the solution, and reflux at 65°C for 24h under the cooling of circulating water. Removal of (MI,n-P)-TiO imprinted with target contaminants 2 The / BDD electrode was rinsed thre...

Embodiment 2

[0043] Immerse BDD in aqua regia and boil for 30min to completely remove the organic and inorganic stains on the surface, then place it in 3M H 2 SO 4 In the electrolyte, a bias voltage of +3.5V was applied for 20 min to obtain a hydrophilic BDD surface with -OH terminals, and finally ultrasonically cleaned with ethanol and purified water, respectively. Prepare 45mL containing 0.05M TiOSO 4 and 5M H 2 SO 4 Then add 8mL of concentrated hydrochloric acid and 20mg of the target pollutant (bisphenol A), and stir vigorously at room temperature for 10h to completely dissolve it. Finally, adjust the pH of the mixed solution to 1.5 with ammonia water to prepare a precursor solution. Put the pre-treated BDD (10×45mm) electrode into a 100mL round bottom flask, pour the prepared precursor solution, soak the BDD electrode in the solution, and reflux at 90°C for 48h under the cooling of circulating water. Removal of (MI,n-P)-TiO imprinted with target contaminants 2 The / BDD electrode ...

Embodiment 3

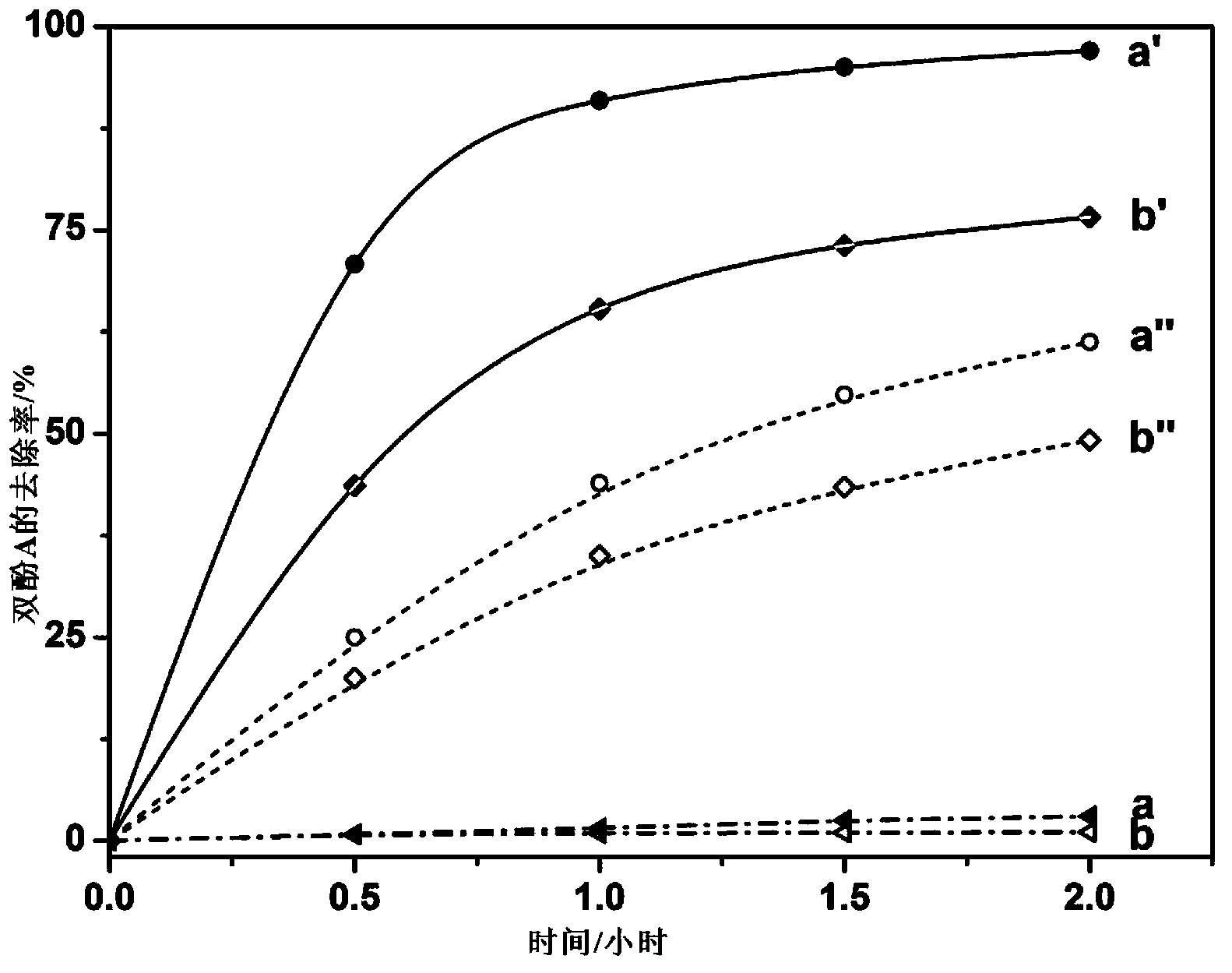

[0045] Adopt the (MI, n-P)-TiO that prepares in the embodiment 1 2 / BDD electrode with non-imprinted TiO 2 / BDD Electrode Photocatalytic Oxidative Degradation of Simulated Wastewater.

[0046] The photoelectrocatalytic degradation is carried out in a semi-cylindrical single-cell reactor, and a cup with circulating water is added to keep the temperature of the reaction system at room temperature. During the degradation, magnetrons are used to continuously stir to enhance mass transfer. With the electrode prepared in Example 1 as the anode, the Ti plate as the counter electrode, the electrode area is 4cm 2 , keep the electrode distance 1cm. A high-pressure mercury lamp with a power of 300W (main wavelength 365nm) was selected as the ultraviolet light source, and the radiation intensity was 15mW cm -2 . Use 20mgL -1 (0.088mM) BPA and 50mg L -1 (0.347mM) 2-NP (2-naphthol), 0.1M Na 2 SO 4 The mixed solution of the supporting electrolyte is used as the degradation simulated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com