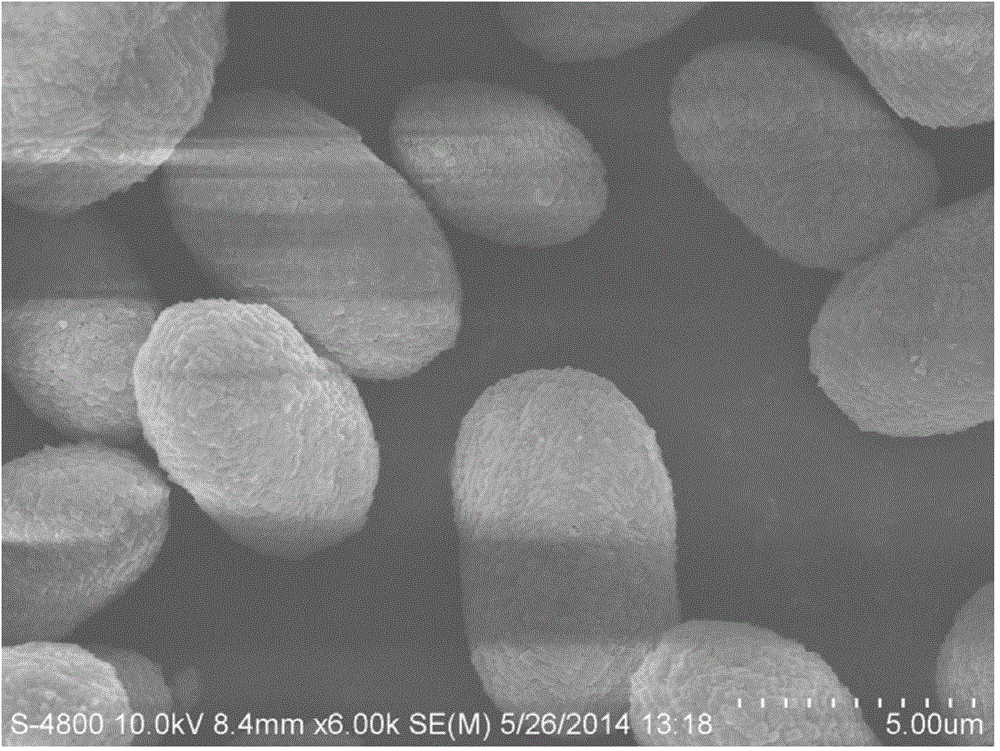

Preparation method of ellipsoidal ion-doped hydroxyapatite microspheres with porous surface

A technology of hydroxyapatite and ion doping, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems that are not conducive to the biomedical application of HA microsphere materials, achieve high specific surface area, and simple preparation method Controllable, inexpensive to prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of Ellipsoidal Calcium Carbonate Microspheres

[0042] (1). Weigh an appropriate amount of calcium nitrate, dissolve it in deionized water, and carry out mechanical stirring for 1 week at 0°C to prepare a 2mol / L calcium nitrate solution;

[0043] (2). Weigh an appropriate amount of sodium carbonate, dissolve it in deionized water, and carry out mechanical stirring for 1 week at 0°C to prepare a 2mol / L sodium carbonate solution;

[0044] (3). Adjusting the reaction temperature to be 0°C, the reaction temperature is 0°C and under the mechanical stirring condition of 3000rpm at the stirring speed, the calcium nitrate solution obtained in step (1) is quickly added to the step (2L / min) with a speed of 2L / min 2) in the sodium carbonate solution obtained; after reacting for 1 week, filter and wash to obtain ellipsoidal calcium carbonate microspheres;

[0045] 2. Preparation of ellipsoidal ion-doped HA

[0046] (a). Weigh an appropriate amount of diammonium hyd...

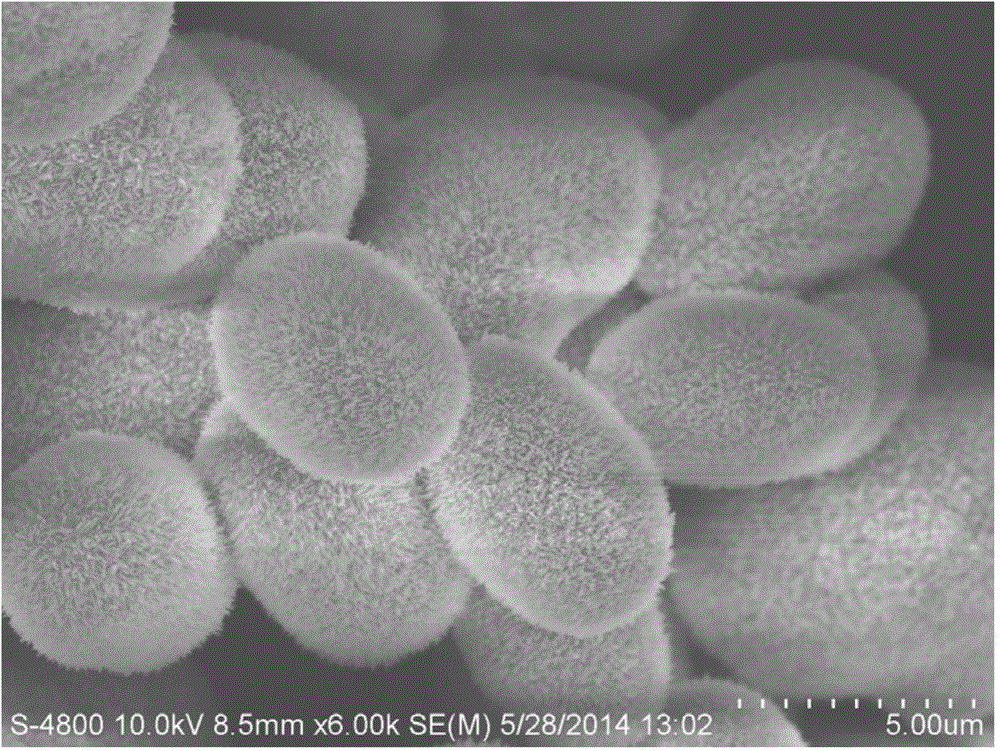

Embodiment 2

[0051] 1. Preparation of Ellipsoidal Calcium Carbonate Microspheres

[0052] (1). Weigh an appropriate amount of calcium chloride, dissolve it in deionized water, and carry out mechanical stirring for 6 hours at -3°C to prepare a 1mol / L calcium chloride solution;

[0053] (2). Weigh an appropriate amount of potassium carbonate, dissolve it in deionized water, and carry out mechanical stirring for 6 hours at -3°C to prepare a 1mol / L potassium carbonate solution;

[0054] (3).Regulate the reaction temperature to be -3°C. Under the mechanical stirring condition that the reaction temperature is -3°C and the stirring speed is 2000rpm, the calcium chloride solution obtained in step (1) is rapidly stirred at a speed of 1.5L / min. Join in the potassium carbonate solution that step (2) obtains; After reacting for 9 hours, filter, obtain ellipsoidal calcium carbonate microspheres after washing;

[0055] 2. Preparation of ellipsoidal ion-doped HA

[0056] (a). Weigh an appropriate amoun...

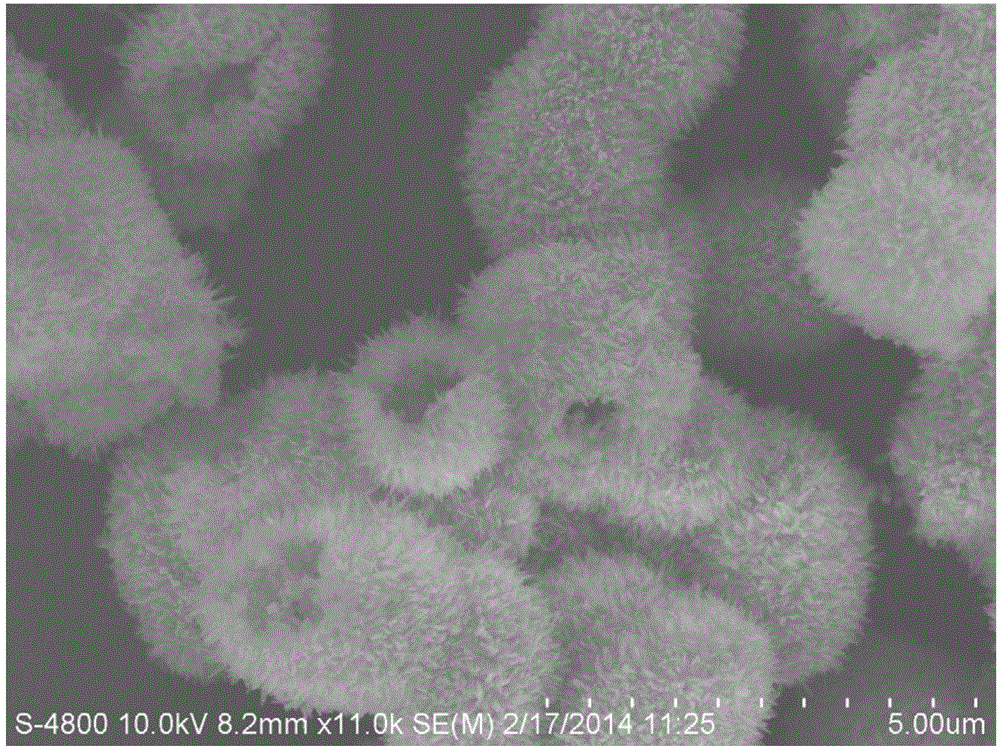

Embodiment 3

[0061] 1. Preparation of Ellipsoidal Calcium Carbonate Microspheres

[0062] (1). Weigh an appropriate amount of calcium nitrate, dissolve it in deionized water, and mechanically stir it for 1 second at -5°C to prepare a 0.001mol / L calcium nitrate solution;

[0063] (2). Weigh an appropriate amount of ammonium carbonate, dissolve it in deionized water, and carry out mechanical stirring for 1 second at -5°C to prepare a 0.001mol / L ammonium carbonate solution;

[0064] (3). Adjust the reaction temperature to be -5°C. Under the mechanical stirring condition that the reaction temperature is -5°C and the stirring speed is 3000rpm, the calcium nitrate solution obtained in step (1) is quickly added at a speed of 0.001L / min In the ammonium carbonate solution that step (2) obtains; After reacting for 1 week, filter, obtain ellipsoidal calcium carbonate microspheres after washing;

[0065] 2. Preparation of ellipsoidal ion-doped HA

[0066] (a). Weigh an appropriate amount of dipotass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com