Method of preparing glass with surface antibacterial property by photopolymerization

A technology of photopolymerization and glass, applied in the field of surface antibacterial modification, can solve the problems of easy falling off, decreased antibacterial effect, time and energy consumption, etc., and achieve the effect of high bonding strength, good inhibition effect, and excellent antibacterial property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

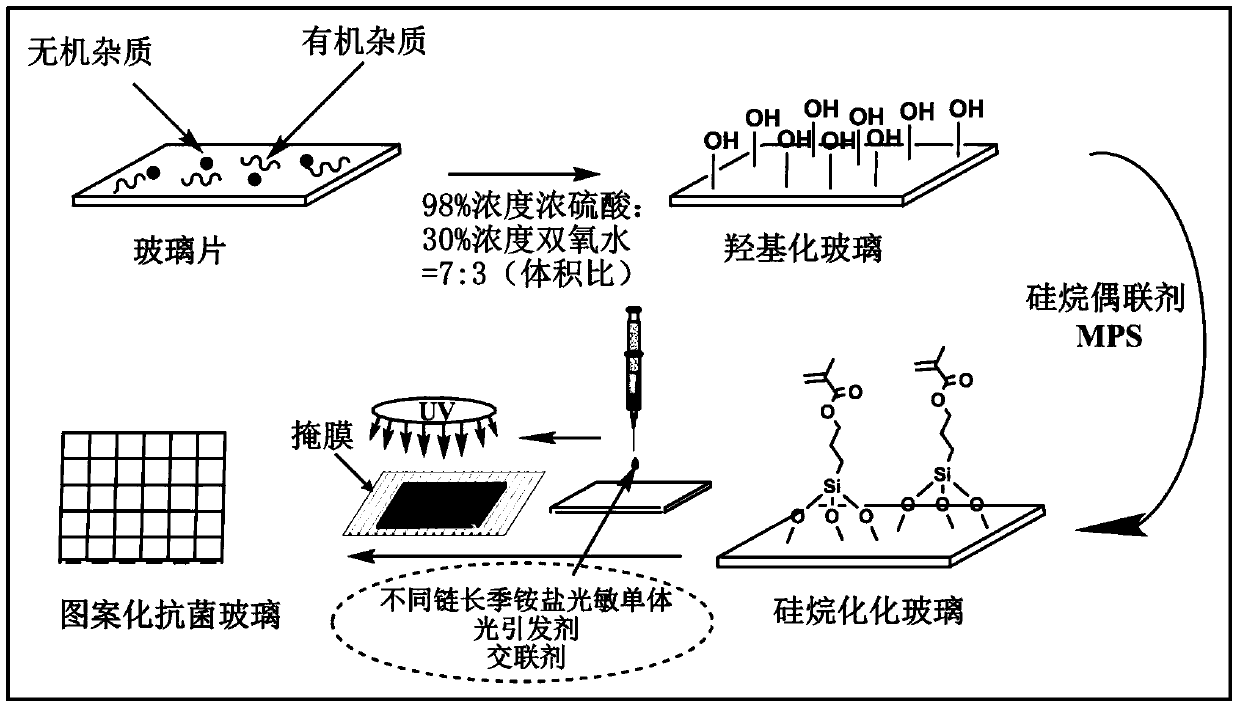

[0019] (1), immerse the glass slices in deionized water, ethanol, and acetone for ultrasonic treatment for 5 minutes, blow dry with nitrogen, and then put them into "cannibal acid" solution (volume ratio of 98% concentrated sulfuric acid to 30% hydrogen peroxide is 7:3) ) for 5 hours.

[0020] (2), silanized glass: prepare the toluene solution of γ-methacryloxypropyltrimethoxysilane (MPS) (the ratio of toluene and silane coupling agent is: 10mL toluene: 5mg silane coupling agent, use Acetic acid is used to adjust the pH value to 3.5), and the hydroxylated glass in step (1) is immersed therein for 2 hours. The hydrolysis of the methoxy groups of MPS and the dehydration condensation of the hydroxyl groups on the glass surface give silanized glass.

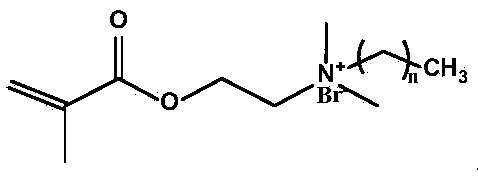

[0021] (3), configure long-chain quaternary ammonium salt photosensitive monomer photopolymerization system (6QAS-46wt.%, 2-hydroxyl-2-methyl-1-phenyl-1-acetone-3wt.%, trimethylolpropane Triacrylate-0.5wt.%, 1,6-hexanediol diacryla...

Embodiment 2

[0024] (1), immerse the glass sheet in deionized water, ethanol, and acetone for ultrasonic treatment for 10 minutes, blow dry with nitrogen, and then put it into the "cannibal acid" solution (98% concentrated sulfuric acid and 30% hydrogen peroxide volume ratio 7:3 ) for 1 hour.

[0025] (2), silanized glass: prepare the toluene solution of γ-methacryloxypropyltrimethoxysilane (MPS) (the ratio of toluene and silane coupling agent is: 10mL toluene: 10mg silane coupling agent, use Acetic acid is used to adjust the pH value to 3), and the hydroxylated glass in step (1) is immersed therein for 1 hour. The hydrolysis of the methoxy groups of MPS and the dehydration condensation of the hydroxyl groups on the glass surface give silanized glass.

[0026] (3), configuration of long-chain quaternary ammonium salt photosensitive monomer photopolymerization system (7QAS-20wt.%, 1-hydroxy-cyclohexyl-phenyl ketone-1wt.%, 1,6-hexanediol diacrylate -2wt.%, dichloromethane-77wt.%), coated o...

Embodiment 3

[0029] (1), immerse the glass sheet in deionized water, ethanol, and acetone for ultrasonic treatment for 15 minutes, dry it with nitrogen, and then put it into the "cannibal acid" solution (the volume ratio of 98% concentrated sulfuric acid and 30% hydrogen peroxide is 7:3 ) for 5 hours.

[0030] (2), silanized glass: prepare the toluene solution of γ-methacryloxypropyltrimethoxysilane (MPS) (the ratio of toluene and silane coupling agent is: 10mL toluene: 5mg silane coupling agent, use Acetic acid is used to adjust the pH value to 4), and the hydroxylated glass in step (1) is immersed therein for 10 hours. The hydrolysis of the methoxy groups of MPS and the dehydration condensation of the hydroxyl groups on the glass surface give silanized glass.

[0031] (3), configuration of long-chain quaternary ammonium salt photosensitive monomer photopolymerization system (8QAS-70wt.%, 2,4,6-trimethylbenzoylphosphonic acid ethyl ester-1.5wt.%, 1-hydroxyl-ring Hexyl-phenyl ketone-1.5w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com