Switch contact capable of resisting electric arc erosion and preparation method thereof

A switch contact and tungsten alloy technology, applied in the field of arc ablation resistant tungsten alloy switch contact and its preparation, can solve the problems of low manufacturing cost, short life, large on-current and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The following are examples of making contacts with tungsten alloy coatings.

[0063] Plating solution composition: sodium tungstate 100g / L, sodium hypophosphite 35g / L, sodium citrate 50g / L, potassium sodium tartrate 30g / L, ammonium sulfate 30g / L, sodium pyrophosphate 24g / L, potassium iodate 40mg / L, sodium thiosulfate 32mg / L, sodium lauryl sulfate 1g / L. Ammonia water is added in an appropriate amount to maintain the pH value of the plating solution between 8.5 and 9.5.

[0064] Routing:

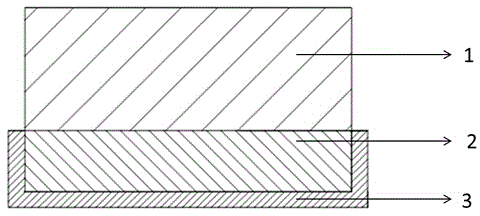

[0065] The metal sheet layer 2 is made of a 0.1 mm thick zinc white copper sheet with a HV hardness of 120 to 180 and a copper content of about 55% as the metal base material. The reason for choosing zinc white copper is that zinc white copper has excellent comprehensive mechanical properties, excellent corrosion resistance, good cold and hot processing formability, and is suitable for manufacturing various elastic components. The smooth zinc-nickel-nickel copper sheet is mechanical...

Embodiment 2

[0071] The following are examples of the preparation of contacts containing tungsten alloy coatings.

[0072] Plating solution composition: sodium tungstate 90g / L, nickel sulfate 10g / L, basic nickel carbonate 16g / L, sodium hypophosphite 25g / L, sodium citrate 50g / L, potassium sodium tartrate 30g / L, ammonium sulfate 30g / L, sodium pyrophosphate 24g / L, potassium iodate 40mg / L, sodium thiosulfate 32mg / L, sodium lauryl sulfate 1g / L, sodium o-sulfonylimide 20g / L. Ammonia water is added in an appropriate amount to maintain the pH value of the plating solution between 8.5 and 9.5.

[0073] Routing:

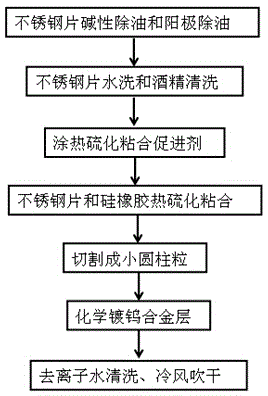

[0074] Such as figure 2 As shown, a 0.075mm thick flat stainless steel sheet (model 304) is subjected to alkaline degreasing and anodic degreasing, and then cleaned with tap water, then distilled water and alcohol, and one side of it is covered with a rubber-metal adhesive. Mixture (U.S. Rohm and Haas Megum 3270) for primer treatment, and then, the treated side of the primer, and a me...

Embodiment 3

[0079] Using 400-mesh stainless steel plain mesh (stainless steel type 304) to replace the stainless steel sheet in Example 2, using the process and chemical plating solution in Implementation 2, the contacts produced also have lower contact resistance and better contact resistance. Arc ablation resistance performance.

[0080] The 400-mesh stainless steel mesh has very small mesh, and when it is molded with silicone rubber, the silicone rubber will not penetrate the mesh of the stainless steel mesh. If you choose a stainless steel mesh with a small mesh number, such as a stainless steel mesh below 80 mesh, there will be a technical problem that silicone rubber penetrates the stainless steel mesh during molding. Therefore, the contact with the tungsten alloy coating 3 needs to be prepared by using a stainless steel mesh with an enlarged mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com