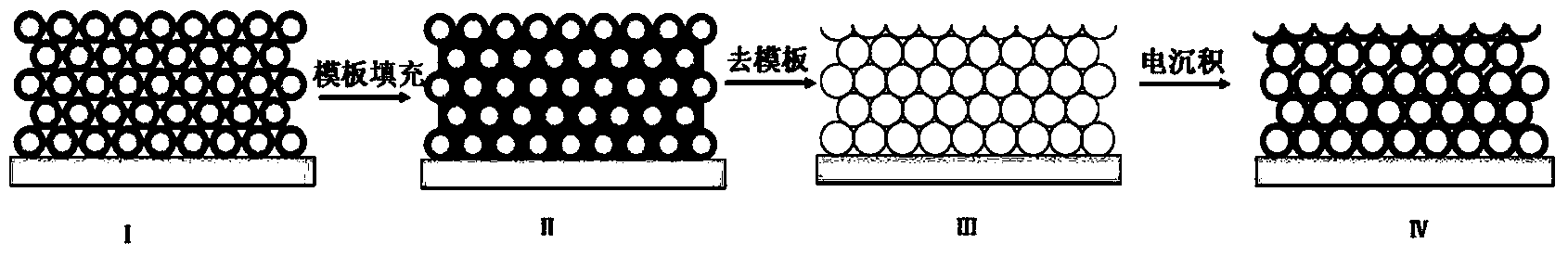

Method for preparing solar cell in inverse opal composite structure

A technology of solar cells and composite structures, applied in the direction of photosensitive equipment, etc., can solve the problems of low light utilization rate and achieve the effects of wide applicability, increased current, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of colloidal crystal template

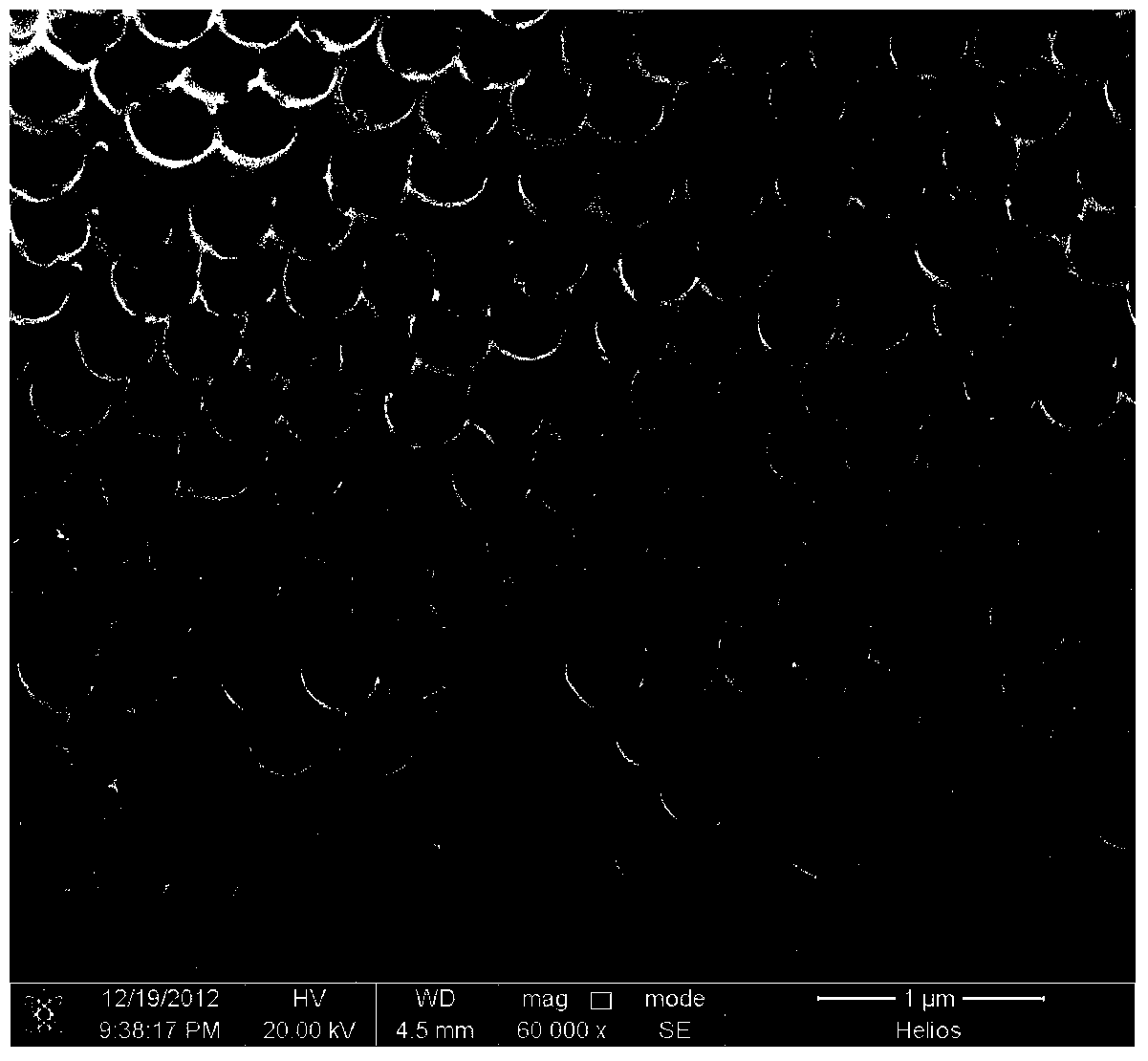

[0043] The silicon wafer was ultrasonically cleaned with distilled water for 10 minutes to remove floating dust, then scrubbed with acetone, then ultrasonically cleaned with absolute ethanol for 10 minutes, then ultrasonically cleaned in ultrapure water for 10 minutes, and finally dried in nitrogen flow; Colloidal microspheres and ultrapure water are put into a flat-bottomed test tube to prepare polystyrene microspheres with a mass concentration of 0.01%, a particle size distribution of 100nm-1000nm, good monodispersity, and a particle size deviation of figure 2 The self-assembled colloidal crystal template shown;

[0044] 2. Preparation of titanium dioxide inverse opal

[0045] 1. Preparation of titanium dioxide sol

[0046] A solution: 2.43ml butyl titanate and 8.08ml absolute ethanol were mixed and stirred for 15-20min;

[0047]Solution B: 0.5ml ultrapure water + 10ml absolute ethanol + 0.01ml 37wt% concentrated hydro...

Embodiment 2

[0056] 1. Preparation of colloidal crystal template

[0057] Ultrasonic the copper sheet with distilled water for 20 minutes to remove floating dust, then scrub it with acetone, then ultrasonically clean it with absolute ethanol for 20 minutes, then ultrasonically clean it in ultrapure water for 20 minutes, and finally dry it in nitrogen flow; Colloidal microspheres and ultrapure water are put into a flat-bottomed test tube to prepare polystyrene microspheres with a mass concentration of 3%, microsphere particle size distribution of 100nm-900nm, good monodispersity, and particle size deviation <3%. Emulsion, immerse the cleaned copper sheet in the polystyrene microsphere emulsion, the immersion angle of the copper sheet is 75° with the emulsion liquid surface, and then place the flat-bottomed test tube in a thermostat with a temperature of 55°C for 72 hours, keep The relative humidity in the incubator is 75%-80%. After the solvent is completely volatilized, the self-assembled ...

Embodiment 3

[0070] 1. Preparation of colloidal crystal template

[0071] Ultrasonic the nickel sheet with distilled water for 15 minutes to remove floating dust, then scrub it with acetone, then ultrasonically clean it with methanol for 15 minutes, then ultrasonically clean it in ultrapure water for 15 minutes, and finally dry it in nitrogen flow; Put the spherical particles and 1% ethanol aqueous solution into a flat-bottomed beaker, and prepare polystyrene with a mass concentration of 0.5%, a microsphere particle size distribution of 100nm-1000nm, good monodispersity, and a particle size deviation of <3%. Microsphere emulsion, immerse the cleaned nickel sheet in the polystyrene microsphere emulsion, the immersion angle of the nickel sheet is 80° to the emulsion liquid surface, and then place the flat-bottomed beaker in a thermostat with a temperature of 50°C for 48 hours , keeping the relative humidity in the incubator at 70%-75%, and after the solvent is completely volatilized, a self-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com