Zinc oxide microspheres and preparation method thereof

A zinc oxide, microsphere technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology for materials and surface science, etc., to achieve strong controllability of morphology, easy operation, strong operability and The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.1 In 50 mL of deionized water, add 0.0025 mol of zinc nitrate and stir at room temperature for 20 min.

[0033] 1.2 Add 0.0075 mol of hexamethylenetetramine (HMT) to the solution described in 1.1, and stir at room temperature for 20 minutes to obtain a homogeneous solution.

[0034] 1.3 Add 0.0005 mol of surfactant tartaric acid to the solution described in 1.2, and stir at room temperature for 20 minutes to obtain a uniform solution.

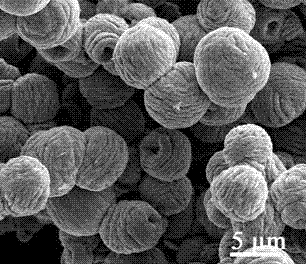

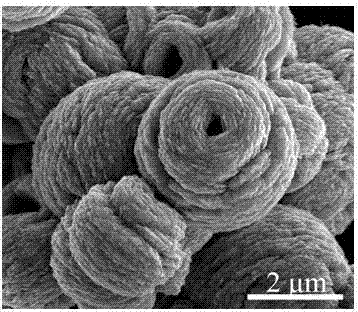

[0035] 1.4 Transfer the solution described in 1.3 to a 100mL reactor, heat it in an oven to 150°C, and react for 6h. The sample after being cooled with the furnace is subjected to centrifugal washing to obtain wool-like zinc oxide microspheres (such as figure 2 shown). The structural characteristics of the obtained wool-like zinc oxide microspheres are uniform in size and about 4.5-6.5 μm in diameter.

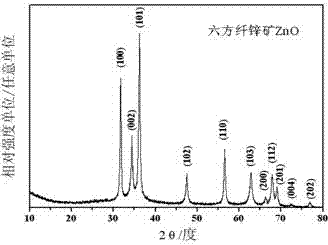

[0036] figure 1 It is the X-ray diffraction pattern of the sample. It can be seen from the figure that the crystal form of the ob...

Embodiment 2

[0040] The preparation method is the same as in Example 1, except that the amount of hexamethylenetetramine is increased to 0.0125 mol. The obtained wool-like zinc oxide microspheres are similar to those in Example 1, with a diameter of 5-7.5 μm.

[0041] Figure 4 It is a low-magnification scanning electron microscope photo of the sample. It can be seen from the figure that the sample is composed of zinc oxide nanosheets, which are like wool balls, and there is a large hole in the center of some microspheres. The sample has many damages, and the size distribution is uniform. The diameter is 5-7.5 μm. It can be seen from the high-magnification scanning electron microscope photos that there are some small holes on the surface of the microspheres. According to the BET test, the specific surface area of the obtained microspheres is 22.97m 2 / g.

Embodiment 3

[0043] The preparation method is the same as in Example 1, except that the amount of hexamethylenetetramine is reduced to 0.005 mol. The obtained wool-like zinc oxide microspheres have a diameter of 4.8-5.5 μm.

[0044] Figure 5 It is a scanning electron microscope photo of the sample. It can be seen from the figure that the sample is composed of zinc oxide nanoflakes, which are wool-like, uniform in size, with a diameter range of 4.8-5.5 μm, good crystallization, regular shape, and most of the microspheres There is no large hole in the center. The specific surface area of the obtained microspheres was 21.47m after the BET test 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com