Adhesive and preparation method

A technology of adhesives and cross-linking agents, applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve problems such as slow dissolution rate, poor coater runability, poor rheology of coatings, etc. Achieve the effect of improving the water resistance of the coating, improving the running performance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides the preparation method of this kind adhesive, it comprises the steps:

[0027] (1) Thoroughly mix 100 parts by mass of starch or starch derivatives with water, then add 5-40 parts by mass of film-forming aids and keep them at the starch gelatinization temperature (80-90°C) to make the starch fully Gelatinization to obtain a mixed solution; this step is preferably carried out under the protection of an inert gas (nitrogen) to improve the reaction efficiency and reduce the generation of by-products. In this step, if the polymer of starch or starch derivatives is not in the range of 10-200, it is also necessary to add 0.5-5 mass parts of molecular weight regulators to carry out chain scission of starch or starch derivatives when adding film-forming aids , Viscosity reduction treatment to make starch or starch derivatives reach the required molecular weight.

[0028] (2) Adjust the pH value of the mixed solution to 5.0-8.0, and this step can be adjus...

Embodiment 1

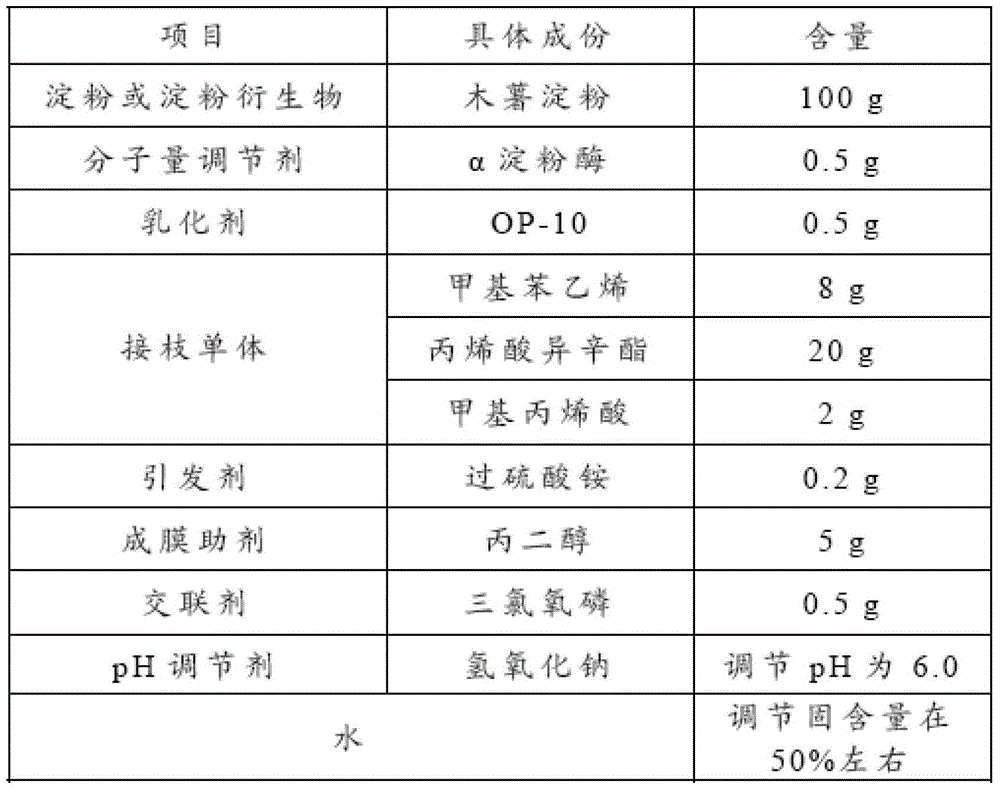

[0041] Please refer to Table 1 for the formula of the adhesive.

[0042] Table I

[0043]

[0044] Preparation of adhesive: Add 90% of the calculated amount of water and tapioca starch into a four-neck flask, stir evenly under nitrogen protection, add α-amylase and propylene glycol and stir thoroughly, heat up to 90°C and gelatinize for 30 minutes; add sodium hydroxide Adjust the pH to 6.0 and dissolve ammonium persulfate with 10% calculated amount of water; add OP-10 and 20% initiator solution (ammonium persulfate aqueous solution) into a four-necked flask; n-butyl ester and methacrylic acid) and the remaining 80% ammonium persulfate aqueous solution were added dropwise to the four-necked flask, the rate of addition was controlled at 1 hour, the reaction temperature was controlled at 60°C, and the graft copolymerization reaction was carried out for 5 hours; The cross-linking agent phosphorus oxychloride is added to the polymerized copolymer emulsion, and the temperature i...

Embodiment 2

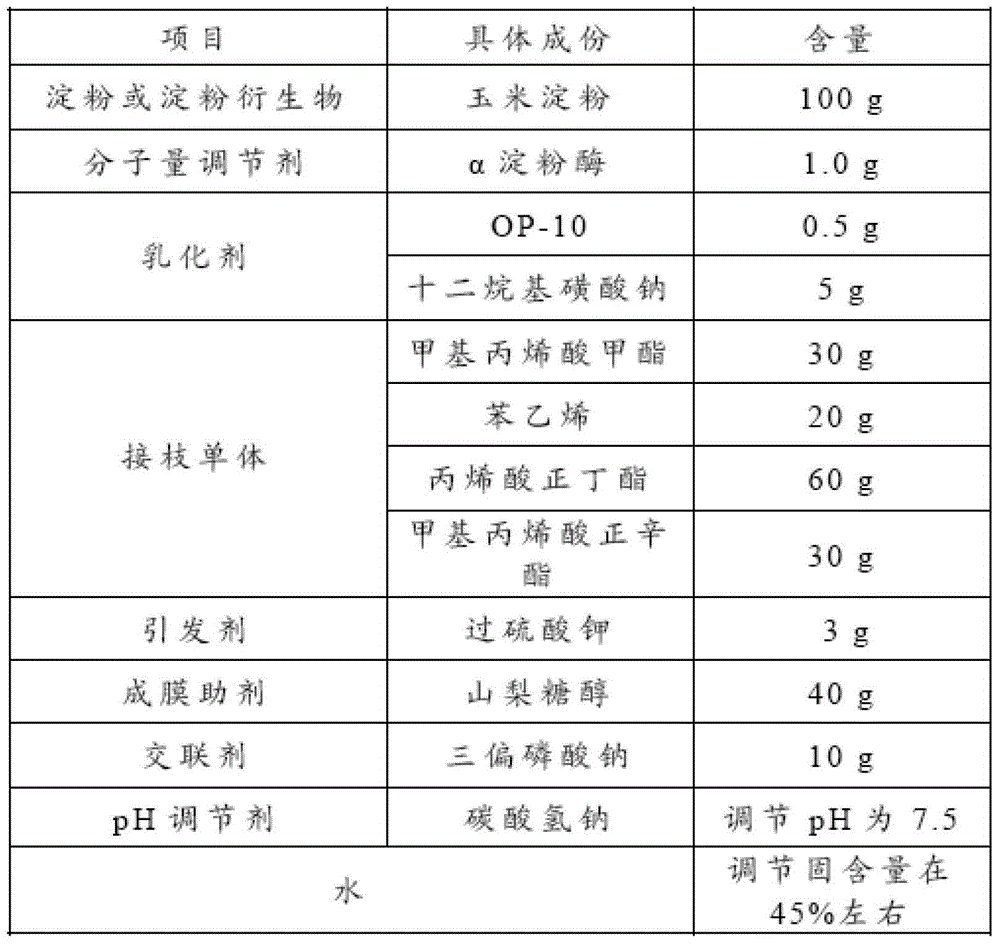

[0046] Please refer to Table 2 for the formula of the adhesive.

[0047] Table II

[0048]

[0049] Preparation of adhesive: Add 80% of the calculated amount of water and tapioca starch into a four-neck flask, stir well under nitrogen protection, add α-amylase and sorbitol and stir thoroughly, heat up to 90°C and gelatinize for 30 minutes; add carbonic acid Sodium hydrogen adjusts the pH to about 7.5; Potassium persulfate and sodium dodecylsulfate are dissolved in 20% calculated amount of water; Add sodium dodecylsulfate aqueous solution and 20% initiator solution (potassium persulfate aqueous solution) into a four-necked flask; the monomers (ie, methyl methacrylate, styrene, n-butyl acrylate, n-octyl methacrylate, and acrylic acid) and the remaining 80% potassium persulfate aqueous solution were added dropwise to the four-necked flask In the process, the dropping rate was controlled at 3 hours, the reaction temperature was controlled at 80°C, and the graft copolymerizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com