Composite additive for M5-M25 methanol gasoline fuels and methanol gasoline thereof

A composite additive, methanol gasoline technology, applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of automobile cold start difficulties, corrosion of metal parts, poor water resistance, etc., to achieve the suppression of oxygen reaction, smooth oil passage and Effect of safety, possibility of overcoming air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

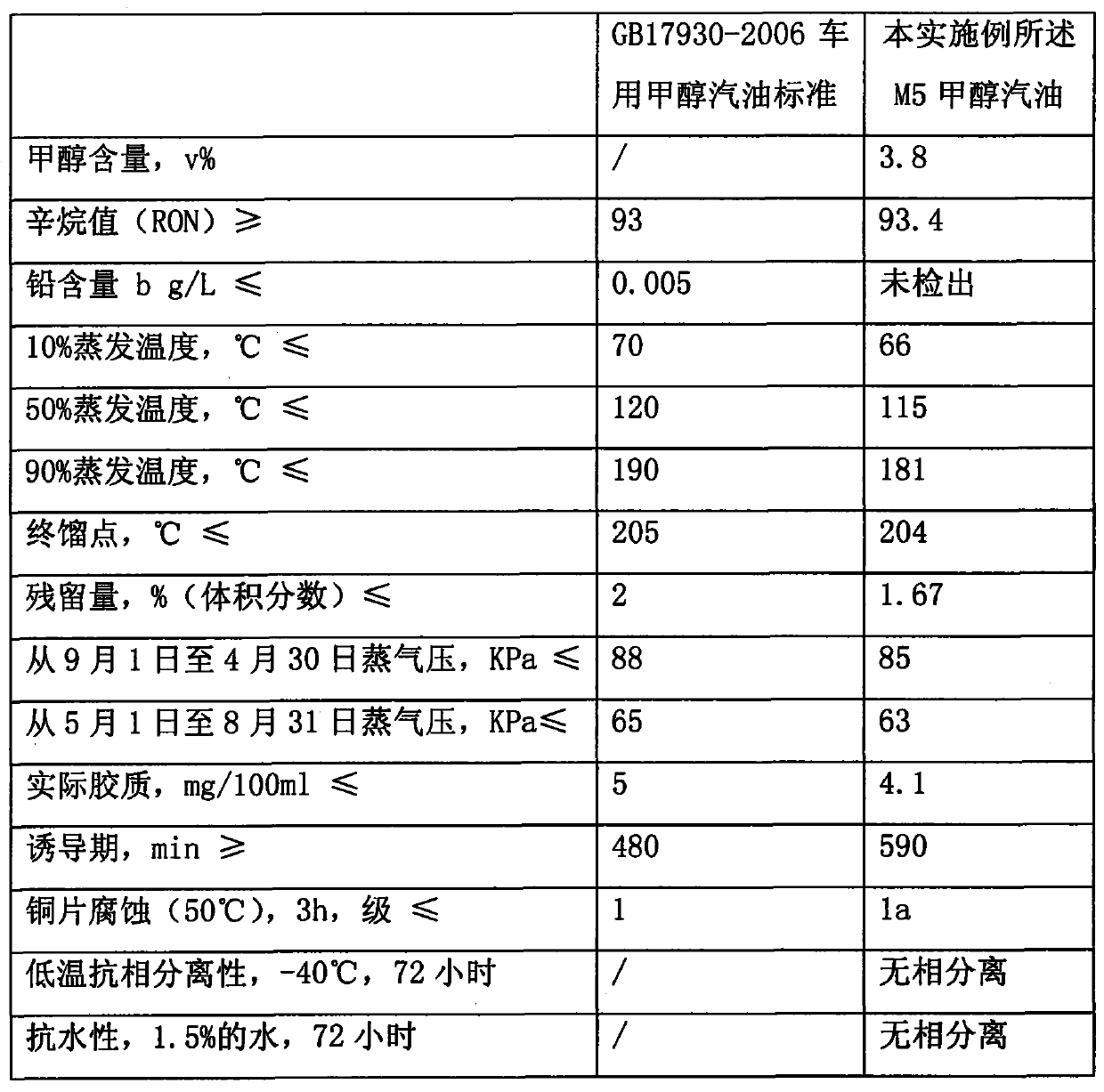

Embodiment 1

[0023] A kind of M5~M25 methanol gasoline composite additive of the present invention is made up of the raw material of following weight ratio:

[0024] Alcohol mixture 24%, wherein, n-butanol: isobutanol: n-octanol: isooctyl alcohol: butanediol: hexanediol: isopentyl glycol: methoxy acetaldehyde dimethyl acetal is 23%: 12 %: 26%: 14%: 7%: 9%: 5%: 4%; ester mixture 16%, of which, ethyl acetate: dimethyl carbonate: ethyl methyl carbonate: dibutyl sebacate: o Dioctyl phthalate is 54%: 13%: 6%: 13%: 14%; ether mixture 25%, of which, straight-chain 8-carbon octanol polyoxyethylene ether: ethyl tert-butyl ether is 13% %: 9%: 78%; aromatic mixture 15%, of which, xylene: ethylbenzene: cumene is 32%: 27%: 41%; dimethoxytetrahydrofuran 5%, alkenyl succinic acid 3%, poly Lysine 2%, 2,4-dimethyl-6-tert-butylphenol 3%, tetraethylenepentamine 4%, 2-methylbenzothiazole 3%.

[0025] The preparation method of the M5-M25 methanol-gasoline compound additive of the present invention belongs to...

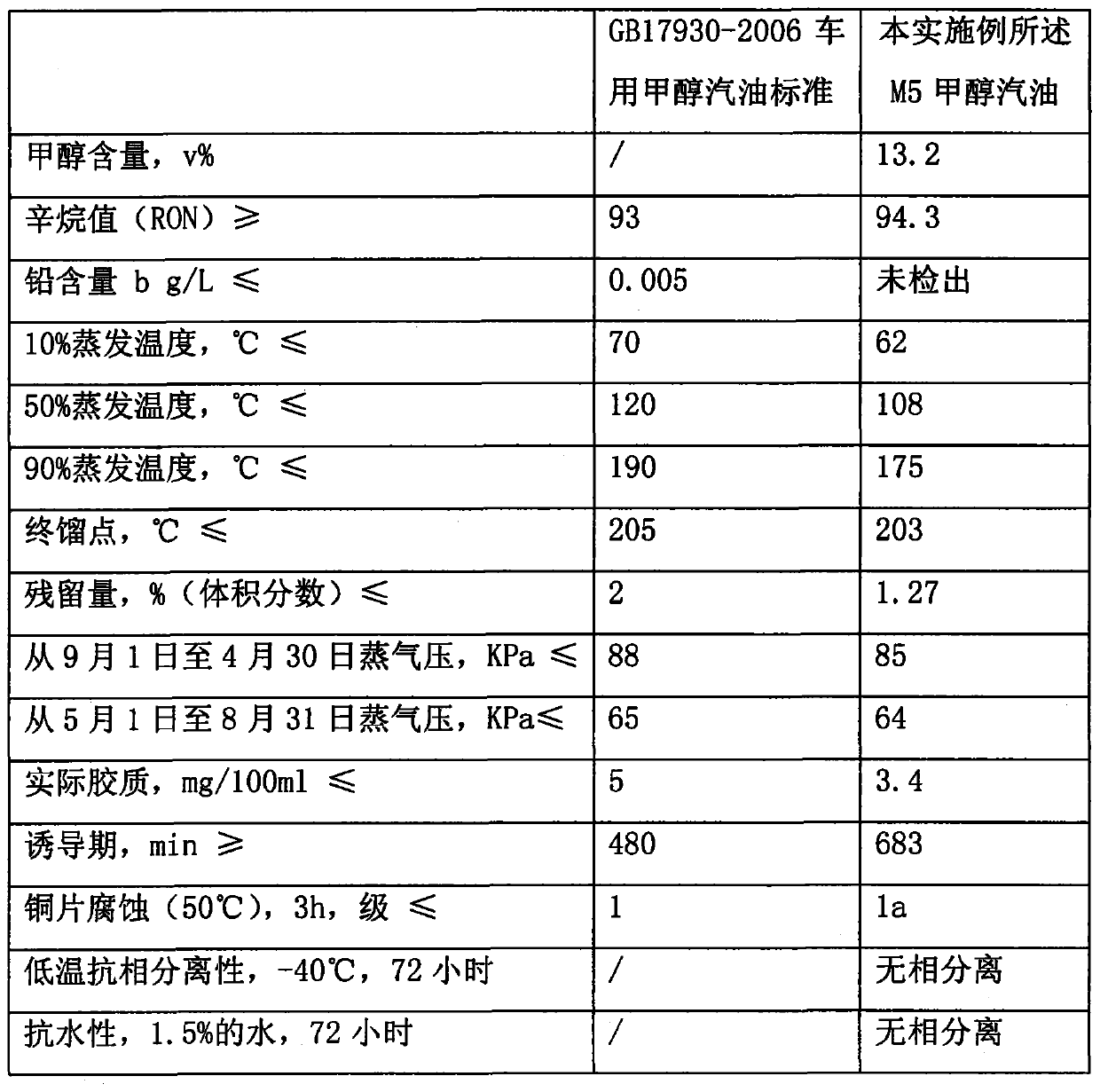

Embodiment 2

[0030] A kind of M5~M25 methanol gasoline composite additive of the present invention is made up of the raw material of following weight ratio:

[0031] Alcohol mixture 26%, wherein, n-butanol: isobutanol: n-octanol: isooctyl alcohol: butanediol: hexanediol: isopentyl glycol: methoxy acetaldehyde dimethyl acetal is 26%: 14 %: 22%: 12%: 9%: 8%: 5%: 4%; ester mixture 14%, of which, ethyl acetate: dimethyl carbonate: ethyl methyl carbonate: dibutyl sebacate: o Dioctyl phthalate is 48%: 16%: 7%: 14%: 15%; ether mixture 23%, of which, the linear 8-carbon octanol polyoxyethylene ether: ethyl tert-butyl ether is 15% %: 10%: 75%; aromatic mixture 16%, of which, xylene: ethylbenzene: cumene is 35%: 29%: 36%; dimethoxytetrahydrofuran 5%, alkenyl succinic acid 4%, poly Lysine 2%, 2,4-dimethyl-6-tert-butylphenol 3%, tetraethylenepentamine 4%, 2-methylbenzothiazole 3%.

[0032] The preparation method of the M5-M25 methanol-gasoline compound additive of the present invention belongs to th...

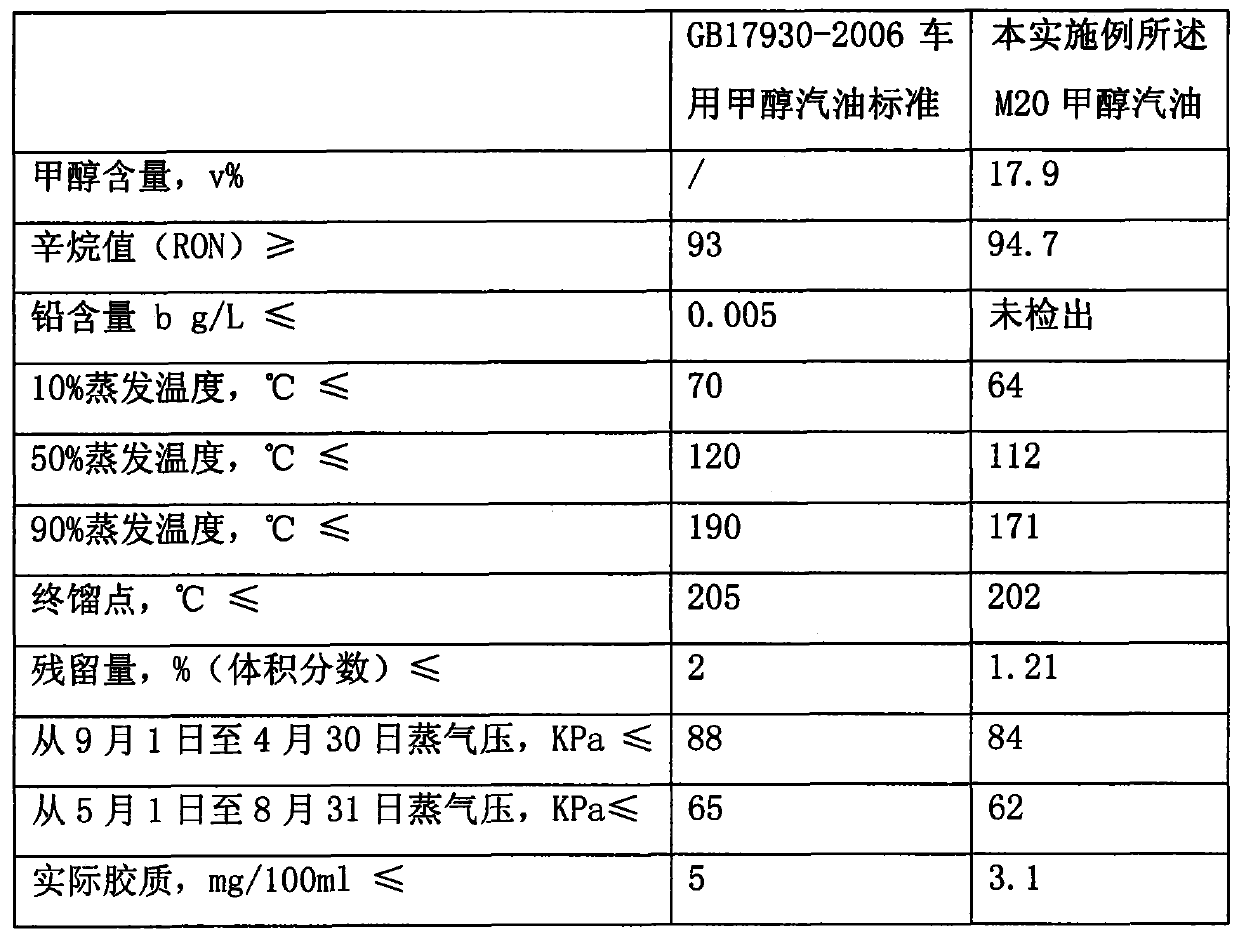

Embodiment 3

[0037] A kind of M5~M25 methanol gasoline composite additive of the present invention is made up of the raw material of following weight ratio:

[0038] Alcohol mixture 28%, wherein, n-butanol: isobutanol: n-octanol: isooctyl alcohol: butanediol: hexanediol: isoprene glycol: methoxy acetaldehyde dimethyl acetal is 29%: 15 %: 21%: 12%: 6%: 8%: 4%: 5%; ester mixture 15%, of which, ethyl acetate: dimethyl carbonate: ethyl methyl carbonate: dibutyl sebacate: o Dioctyl phthalate is 41%: 19%: 140%: 13%: 17%; ether mixture 20%, of which, straight-chain 8-carbon octanol polyoxyethylene ether: ethyl tert-butyl ether is 18 %: 13%: 69%; aromatic hydrocarbon mixture 14%, of which, xylene: ethylbenzene: cumene is 38%: 34%: 28%; dimethoxytetrahydrofuran 6%, alkenyl succinic acid 4%, poly Lysine 3%, 2,4-dimethyl-6-tert-butylphenol 3%, tetraethylenepentamine 4%, 2-methylbenzothiazole 3%.

[0039] The preparation method of the M5-M25 methanol-gasoline compound additive of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com