A waste incineration process

A treatment process and waste incineration technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as harming the environment and human health, high volume expansion rate of solidified body, affecting human health, etc., to achieve high dust removal rate, guarantee Temperature range, the effect of small proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

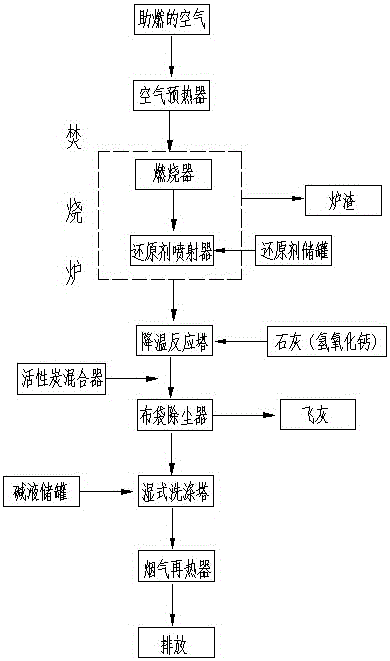

[0019] Such as figure 1 In the waste incineration process shown, firstly, the combustion-supporting air is extracted from the garbage pool, and the combustion-supporting air first passes through the air preheater and then enters the incinerator. In the incinerator, its temperature is 850°C-1050°C. The oxygen concentration is 3% to 5%. Combustion-supporting air and garbage are mixed and burned at high temperature by the burner. After high-temperature combustion, smoke and slag mixed with various substances are produced. The smoke contains a certain amount of nitrogen dioxide and nitrogen oxides. substances, hydrogen chloride, etc., the total amount of which is called NOx. The flue gas rises through a plurality of injection devices on the incinerator, and the injection devices are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com