Method for producing whole soybean peptide vegetable protein drink

A plant protein beverage and soybean polypeptide technology, which is applied in the field of food processing, can solve the problems of high cost, achieve the effects of reducing impact, ensuring stability, and improving biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

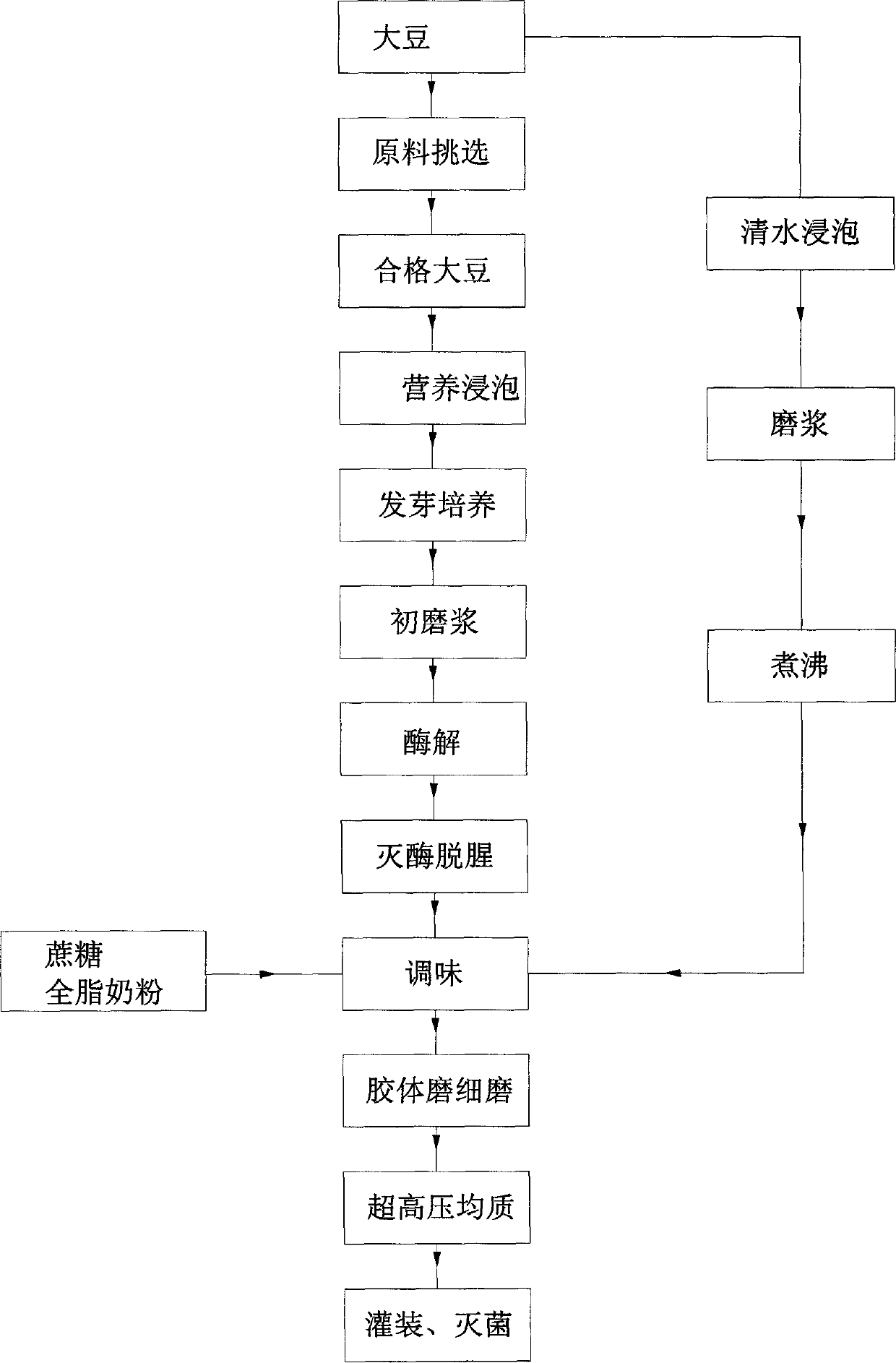

Image

Examples

Embodiment 1

[0024] A production method of whole soybean polypeptide vegetable protein beverage, comprising the following steps:

[0025] (1) Selection of raw materials: select soybeans that are plump, free from insect damage, mildew-free, and full of grains, and set aside;

[0026] (2) Soaking: Soak the selected soybean seeds in 0.03 mg / L 6-benzylaminopurine soaking solution, the solid-liquid ratio of soybeans to the soaking solution is 1:2, after soaking for 12 hours, drain the surface moisture and set aside;

[0027] (3) Germination cultivation: soak the soybeans in step (2), cultivate the soybeans in a constant temperature and humidity incubator with a relative humidity of 75% at 25° C. until the buds are 0.5-2 mm long, and take them out for later use;

[0028] (4) Primary refining: step (3) germinated soybeans are coarsely crushed in a refiner according to the material-to-water ratio of 1:4, and then passed through a 100-mesh colloid mill to obtain slurry 1 for subsequent use; Soak t...

Embodiment 2

[0036] The production method of whole soybean polypeptide vegetable protein beverage comprises the following steps:

[0037] (1) Selection of raw materials: select soybeans that are plump, free from insect damage, mildew-free, and full of grains, and set aside;

[0038] (2) Soaking: Soak the selected soybean seeds in 0.07 mg / L of 6-benzylaminopurine soaking solution, the solid-liquid ratio of the soybeans to the soaking solution is 1:2, after soaking for 20 hours, drain the surface moisture ,spare;

[0039] (3) Germination cultivation: Soak the soybeans in step (2), cultivate soybeans in a constant temperature and humidity incubator with a relative humidity of 80% at 30° C. until the buds are 0.5-2 mm long, and take them out for later use;

[0040](4) initial refining: step (3) germinated soybeans are coarsely crushed in a refiner according to the material-to-water ratio of 1:7, and then 100 mesh colloid mills are used to obtain slurry 1 for subsequent use; After soaking soy...

Embodiment 3

[0048] A production method of whole soybean polypeptide vegetable protein beverage, comprising the following steps:

[0049] (1) Selection of raw materials: select soybeans that are plump, free from insect damage, mildew-free, and full of grains, and set aside;

[0050] (2) Soaking: soak the selected soybean seeds in 0.1 mg / L 6-benzylaminopurine soaking solution, the solid-liquid ratio of the soybeans to the soaking solution is 1:2, after soaking for 24 hours, drain the surface moisture ,spare;

[0051] (3) Germination cultivation: the soybeans soaked in step (2) are cultivated in a constant temperature and humidity incubator at 35° C. and a relative humidity of 90% until the buds are 0.5-2 mm long, and then taken out for later use;

[0052] (4) Primary refining: In step (3), the germinated soybeans are coarsely crushed in a refiner according to the material-to-water ratio of 1:10, and then 100 mesh colloid mills are used to obtain slurry 1, which is set aside; the soybeans i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com