Antibacterial polyvinylidene fluoride membrane and preparation method thereof

A polyvinylidene fluoride film and a polyvinylidene fluoride technology are applied in the field of antibacterial polyvinylidene fluoride film and its preparation, which can solve the problems of limiting practical application, reducing the service life of the film, being easy to detach, etc., and achieving good self-cleaning performance, Easy to operate, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the antibacterial polyvinylidene fluoride film of the present invention includes the following processes:

[0025] (1) Preparation of original polyvinylidene fluoride film containing initiator

[0026] Dissolve polyvinylidene fluoride powder and pore-forming agent in dimethylacetamide, prepare a polyvinylidene fluoride solution with a mass fraction of 10-20%, stir at 60-65°C until uniform; degas the solution, 60-65 Scrape the film at ℃, remove the solvent and air dry. The obtained film is immersed in an acetone solution containing the initiator AIBN, and finally taken out for vacuum drying to obtain the original polyvinylidene fluoride film containing the initiator;

[0027] (2) Preparation of Zwitterionic Polymer Brush-grafted PVDF Film

[0028] Put the original polyvinylidene fluoride membrane containing the initiator into a reaction flask containing a mixed solution of methanol and water, and add a hydrophilic anti-pollution monomer; blow nitrogen ...

Embodiment 1

[0033] 1) Preparation of PVDF membrane containing AIBN initiator: Take 4g of PVDF powder and dissolve 0.7g of PVP in 22ml of N,N-dimethylacetamide (DMAc), configure it as a PVDF casting solution, and stir at 65°C until uniform. The casting solution was vacuum degassed, and it was scraped onto the glass plate with a scraper with a thickness of 200 μm, and placed in a coagulation bath of deionized water at 35°C. After the film was separated from the glass plate, it was soaked in deionized water for 48 hours to remove the residual solvent and then dried. After immersing the obtained PVDF original membrane in the acetone solution of AIBN for 30 minutes, take it out for vacuum drying at room temperature to obtain the PVDF membrane containing the initiator.

[0034] 2) PVDF membrane surface grafting zwitterionic polymer brush: Put 3 original PVDF membranes (3cm×3cm) containing AIBN into a three-necked flask containing 30ml methanol and water mixed solution (30 / 70, w / w) And add 1.25g o...

Embodiment 2

[0038] 1) Preparation of PVDF membrane containing AIBN initiator: same as step 1 in Example 1.

[0039] 2) Grafting zwitterionic polymer brush on the surface of PVDF membrane: same as step 2 in Example 1.

[0040] 3) Preparation of antibacterial polyvinylidene fluoride film: put two prepared zwitterionic polymer brush-grafted vinylidene fluoride film (3cm×3cm) into an Erlenmeyer flask containing silver nitrate solution (0.05 g / L) In the dark place for 10 minutes. After that, the membrane was taken out of the Erlenmeyer flask and placed in an aqueous solution of sodium borohydride (0.1 g / L) for 5 min. The membrane was immersed in deionized water for 12 hours, and then dried in a vacuum beacon at 35°C.

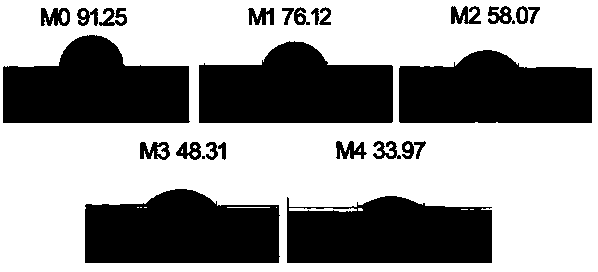

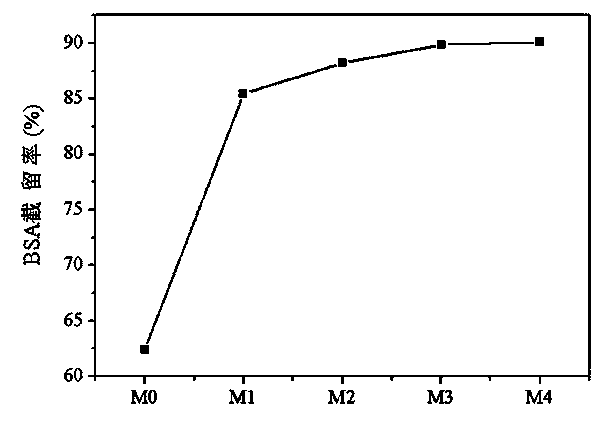

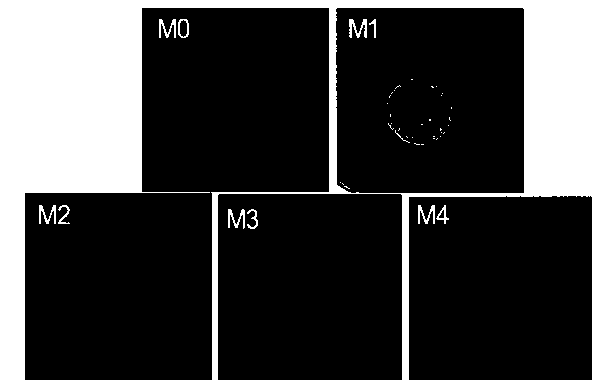

[0041] Comparative experiment The contact angle of the PVDF membrane without surface modification with water reached 91.25°. In this example, the contact angle of the PVDF membrane with water dropped to 48.31° after surface modification. Using bovine serum albumin (BSA) as a polluta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com