Dendritic iron nitride powder and preparation method thereof

A technology of iron nitride and powder, which is applied in the field of dendritic iron nitride powder and its preparation, can solve the problems of high production cost, complex process, and lack of micro-nano structure, and achieve low production temperature, simple process and equipment, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

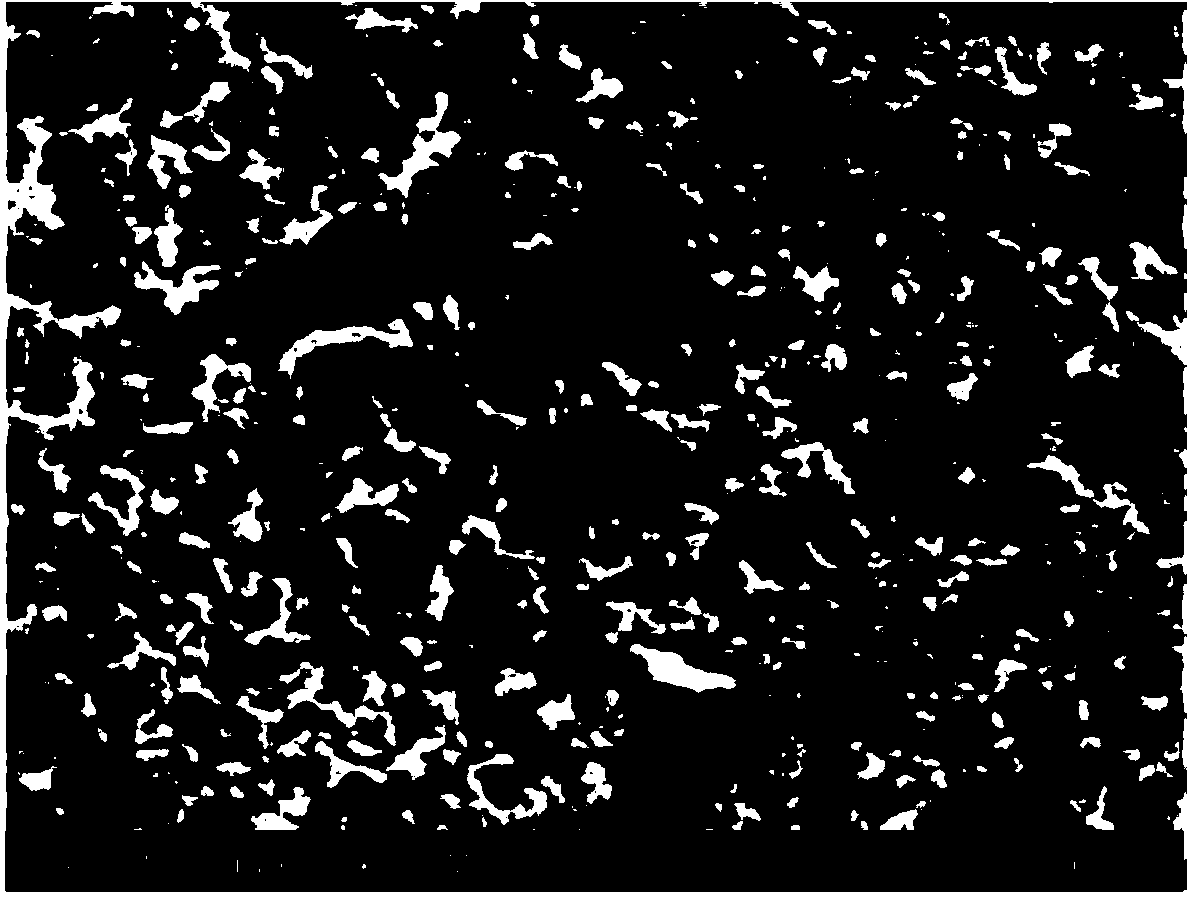

[0038] The steps for preparing dendritic iron nitride powder are as follows: first, use deionized water to prepare K with a concentration of 0.1mol / L 3 [Fe(CN) 6 ] (potassium ferricyanide) aqueous solution, the aqueous solution pH=12 was adjusted with sodium hydroxide. Stir at room temperature for 10 minutes to become a clear solution. Pour 70ml of the solution into a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, tighten the lid of the reaction kettle, put the reaction kettle into an oven, and heat at 140°C. The heat preservation time is 24 hours. After naturally cooling to room temperature, the reaction product was taken out, the resulting red precipitate was centrifuged, washed five times with deionized water and absolute ethanol, and dried at 60°C to obtain dendritic ferric oxide powder.

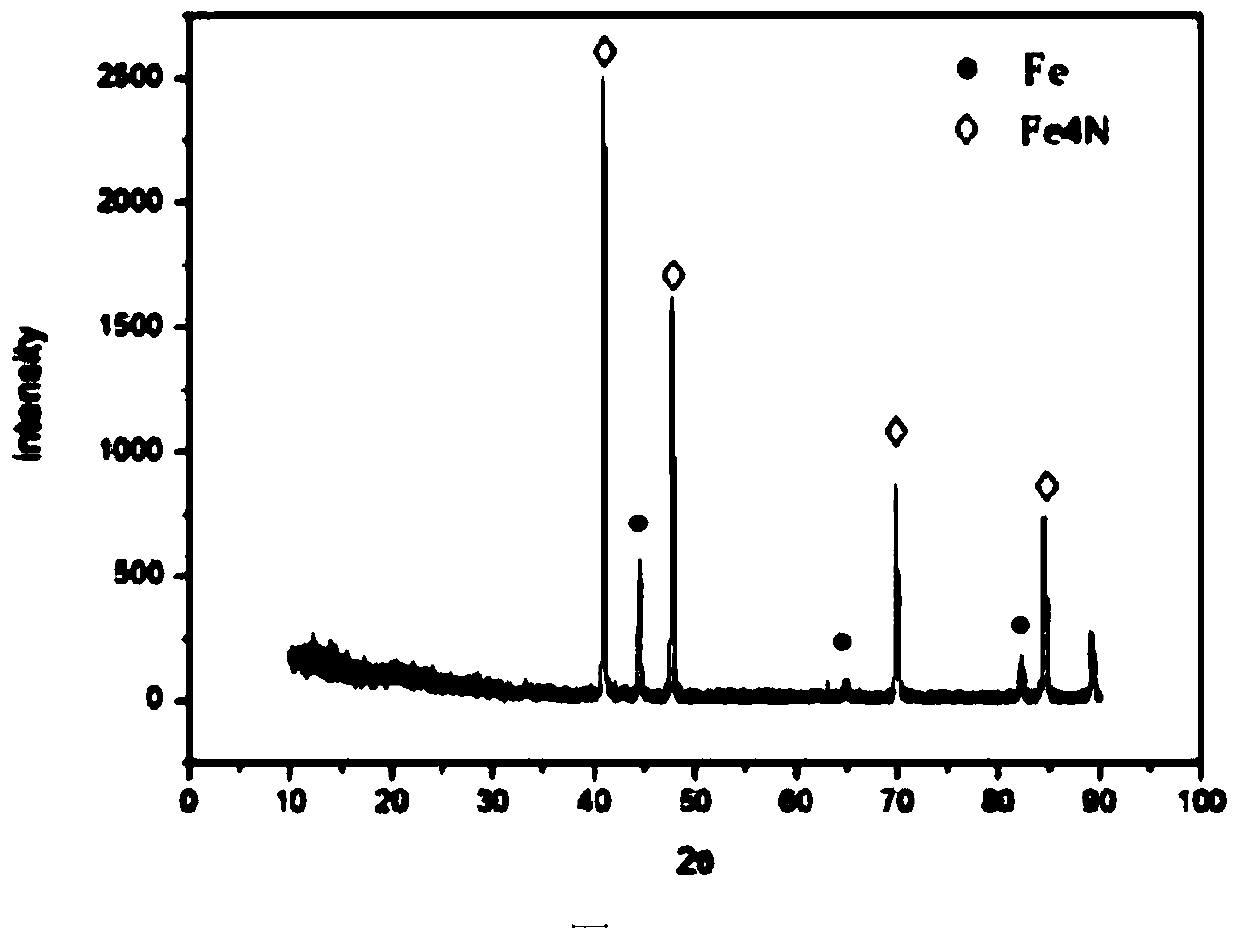

[0039] Put the obtained ferric oxide powder into the nitriding furnace, first pass nitrogen gas to evacuate, then pass through ammonia gas, raise the tempera...

Embodiment 2

[0041] The steps for preparing dendritic iron nitride powder are as follows: firstly, deionized water is used to prepare K 3 [Fe(CN) 6 ] (potassium ferricyanide) aqueous solution, adjust the aqueous solution pH=14 with ammonia water. Stir at room temperature for 10 minutes to become a clear solution. Pour 70ml of the solution into a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, tighten the lid of the reaction kettle, put the reaction kettle into an oven, and heat at 150°C. The heat preservation time is 48 hours. After naturally cooling to room temperature, the reaction product was taken out, the resulting red precipitate was centrifuged, washed with deionized water and absolute ethanol five times each, and dried at 60°C to obtain dendritic ferric oxide powder.

[0042] Put the obtained ferric oxide powder into the nitriding furnace, first pass nitrogen gas to evacuate, then pass through ammonia gas, raise the temperature to 520°C, adjust the nitro...

Embodiment 3

[0044] The steps for preparing dendritic iron nitride powder are as follows: first, deionized water is used to prepare K with a concentration of 0.15mol / L 3 [Fe(CN) 6 ] (potassium ferricyanide) aqueous solution, adjust the aqueous solution pH=8 with ammonia water. Stir at room temperature for 10 minutes to become a clear solution. Pour 350ml of the solution into a 500ml stainless steel reaction kettle lined with polytetrafluoroethylene. Tighten the lid of the reaction kettle, put the reaction kettle into an oven, and heat at 180°C. The heat preservation time is 48 hours. After naturally cooling to room temperature, the reaction product was taken out, the resulting red precipitate was centrifuged, washed with deionized water and absolute ethanol five times each, and dried at 60°C to obtain dendritic ferric oxide powder.

[0045] Put the obtained ferric oxide powder into a tube furnace, first pass nitrogen to evacuate, and then pass a mixed gas of ammonia and hydrogen (volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com