Preparation method and application of graphene oxide/silicon dioxide/polyaniline composite material

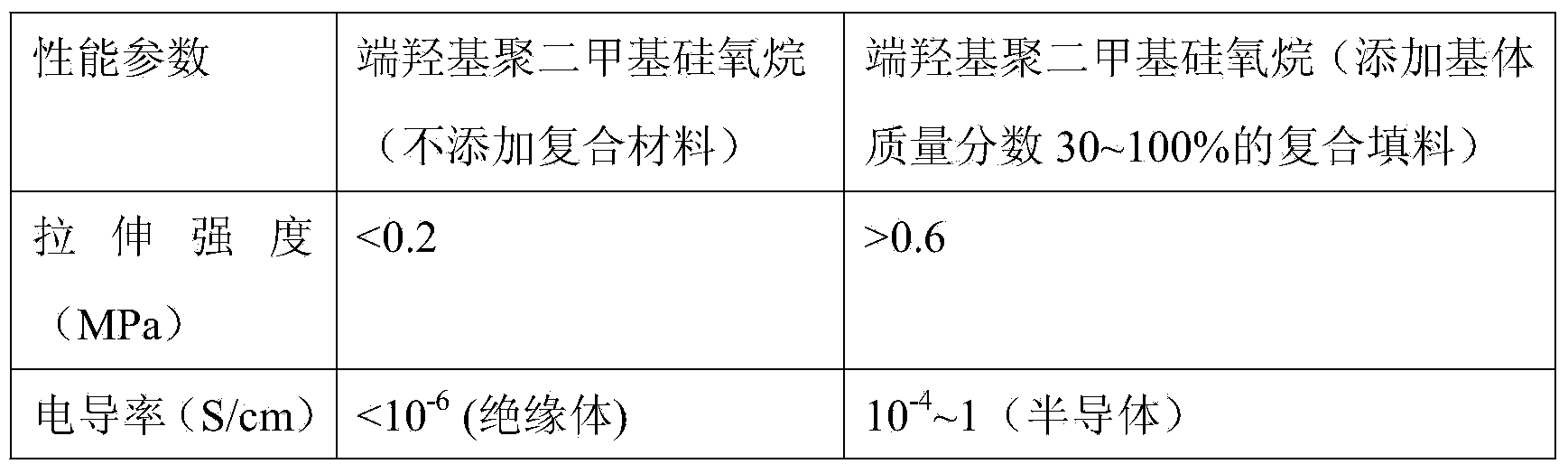

A technology of silicon dioxide and composite materials, which is applied in the field of preparation and application of graphene oxide/silicon dioxide/polyaniline composite materials, can solve the problem of low performance of graphene oxide, and achieve good electrical conductivity, high electrical conductivity and Strength, simple effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) 288mL graphene oxide water dispersion (containing graphene oxide 0.288g, water 288g, 16mol), 5g tetraethyl orthosilicate (2.4×10 -2mol) were mixed evenly, and sodium hydroxide was added to make the pH of the mixed solution 12, stirred and reacted at 15° C. for 12 hours, filtered, washed, and dried to obtain a graphene oxide / silicon dioxide composite material.

[0026] (2) Disperse the product of step (1) in ethylene glycol, add 1.152g aniline (1.24×10 -2 mol), 0.633g concentrated sulfuric acid (6.2×10 -3 mol after stirring evenly, add 5.659g ammonium persulfate (2.48×10 -2 mol) was stirred and reacted at 0°C (ice-water bath) for 4 hours, filtered, washed, and dried to obtain a graphene oxide / silicon dioxide / polyaniline composite material.

[0027] In the composite material obtained in Example 1, the conversion rate of tetraethyl orthosilicate and aniline is approximately equal to 100%, the quality of graphene oxide in the product is about 0.288g, the quality of s...

Embodiment 2

[0029] (1) Mix 6000mL of graphene oxide ethanol dispersion (containing 6g of graphene oxide), 12.195g of sodium silicate (0.1mol), 50g of water (2.8mol) in a reaction vessel, and add 8.719g of nitric acid (0.2mol ) make the mixed solution acidic, stir and react at 80° C. for 10 minutes, filter, wash and dry to obtain the graphene oxide / silicon dioxide composite material.

[0030] (2) Disperse the product of step (1) in isopropanol, add 8g aniline (8.59×10 -2 mol), 33.935g concentrated hydrochloric acid (0.344mol, after stirring evenly, add 3.738g manganese dioxide (4.30×10 -2 mol) was stirred and reacted at 50° C. for 10 minutes, filtered, washed, and dried to obtain a graphene oxide / silica / polyaniline composite material.

[0031] The conversion rate of sodium silicate and aniline in the composite material obtained in Example 2 is approximately equal to 100%, the quality of graphene oxide in the product is about 6g, the quality of silicon dioxide is about 6g, and the quality ...

Embodiment 3

[0033] (1) In a reaction vessel, 1397mL graphene oxide N,N-dimethylformamide dispersion (containing graphene oxide 1.397g), 0.9313g aniline (0.01mol), 1.722g p-toluenesulfonic acid (0.01mol ) and mix evenly, add 1.133g of 30% hydrogen peroxide (0.01mol) and stir at 5°C for 4 hours, centrifuge, wash and dry to obtain a graphene oxide / polyaniline composite material.

[0034] (2) Disperse the product of (1) into 200mL ethanol, add 5.909g tetramethyl orthosilicate (3.88×10 -2 mol), 10g water (0.556mol), 15.8g sulfuric acid (0.155mol) to make the mixed solution acidic, stirred and reacted at 10°C for 12 hours, filtered, washed and dried to obtain graphene oxide / silicon dioxide / polyaniline composite material.

[0035] The conversion ratio of tetramethyl orthosilicate and aniline in the composite material obtained in this embodiment 3 is approximately equal to 100%, and the quality of graphene oxide in the product is about: 1.397g, the quality of silicon dioxide is about 2.328g, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com