Schottky barrier diode chip and production technology thereof

A Schottky potential and production process technology, applied in transistors, electrical components, circuits, etc., can solve the problems of large forward conduction voltage, poor anti-surge ability, easy to burn diodes, etc. The effect of good contact performance and fast chip response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

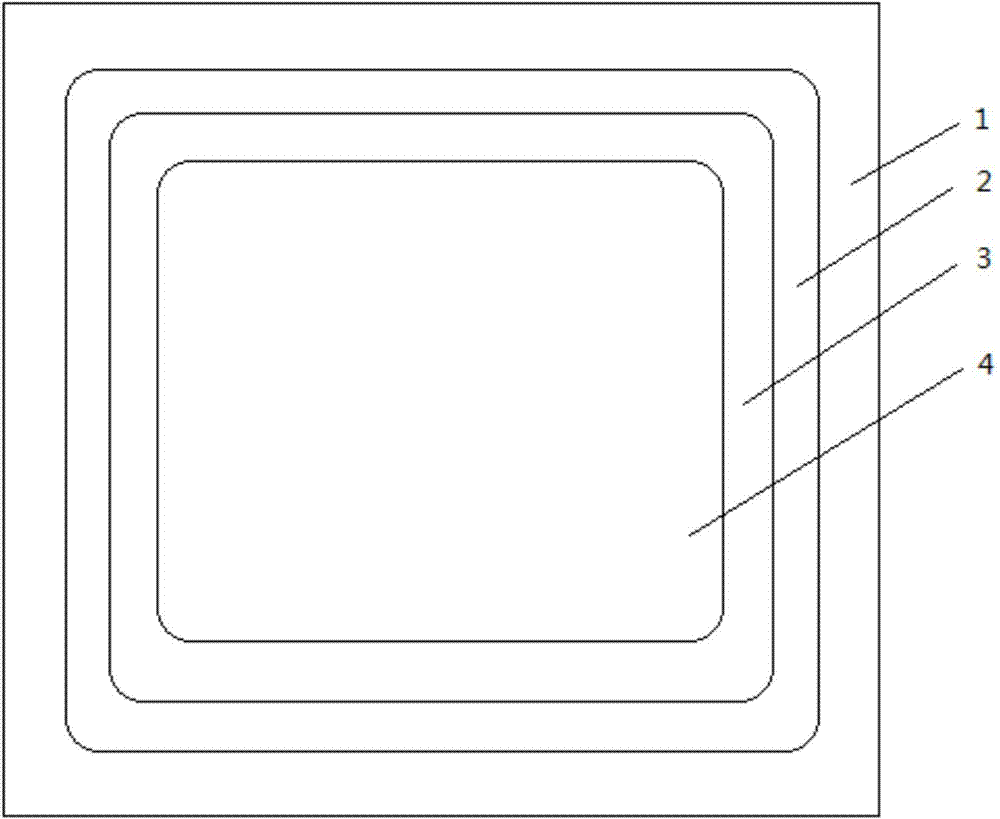

[0066] Such as figure 1 As shown, a Schottky barrier diode chip includes a chip 1, and also includes a terminal groove 2, a protective layer 3 and an electrode 4; the chip 1 is a Schottky barrier diode chip; the electrode 4 is a groove A gate oxide polycrystalline electrode, electrode 4 includes a Schottky region. The Schottky metal in the Schottky area is nickel or chromium, and the electrode 4 of the chip is fused with the Schottky area, so that the chip has a compact structure, better electrical contact performance, and faster chip response during use.

[0067] The protective layer 3 is a PETEOS protective layer 3, which adopts a PETEOS (plasma-enhanced orthoethyl silicate deposition) terminal structure, which reduces the reverse leakage current of the Schottky diode, and the device has better reliability and is suitable for complex environments. The lower diodes are more suitable for use.

[0068] The chip sections are chip 1 , terminal groove 2 , protective layer 3 and ...

Embodiment 2

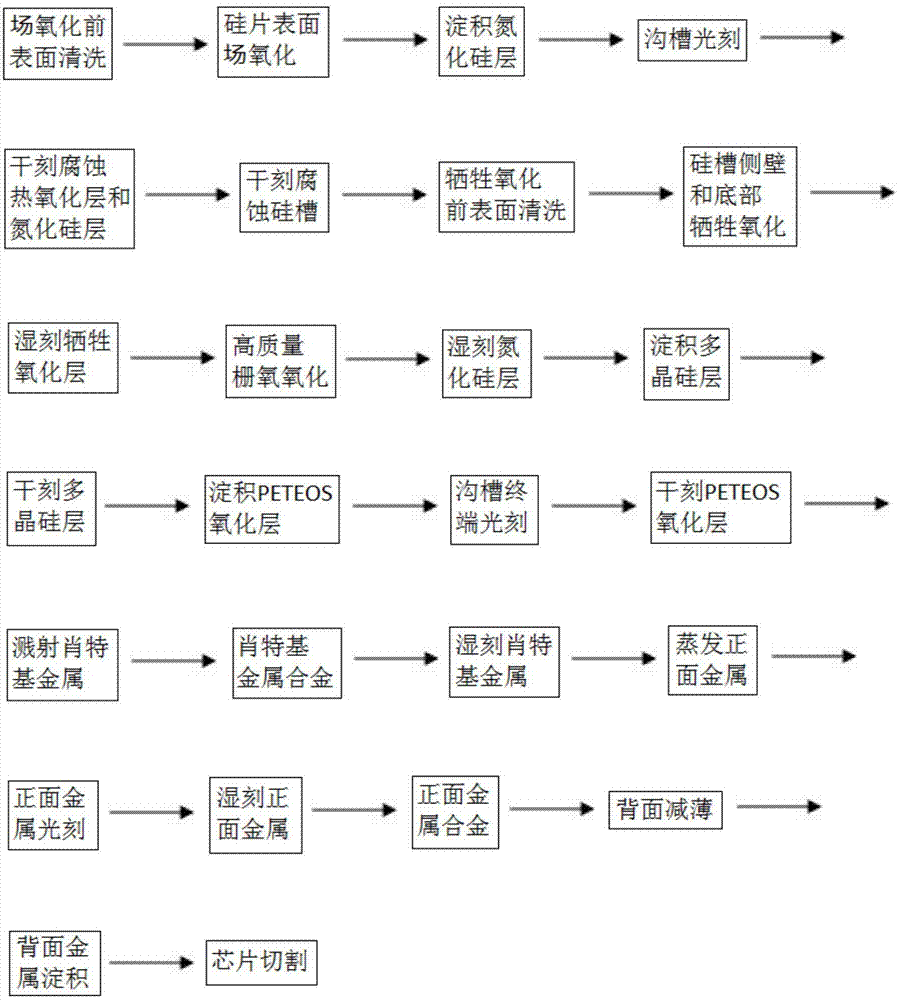

[0112] A production process of a Schottky barrier diode chip, the steps of which are:

[0113] 1) Surface cleaning before field oxidation:

[0114] Configure a hydrofluoric acid solution, which is obtained by mixing a solution with a volume ratio of water:hydrofluoric acid=6:1, and the mass concentration of the hydrofluoric acid solution is 40%;

[0115] Configure No. 1 solution, which is obtained by mixing ammonia water: hydrogen peroxide solution: water = 1:1:5-1:2:7 in volume ratio, and the concentration of ammonia water is 27%;

[0116] Configure No. 2 solution, which is obtained by mixing the volume ratio of hydrogen chloride: hydrogen peroxide solution: water = 1:1:6-1:2:8. The mass concentration of hydrogen chloride is 37%, and the mass concentration of hydrogen peroxide solution is 30%. ;The cleaning sequence is as follows:

[0117] a. Soak the silicon wafer with hydrofluoric acid solution for 30s, and rinse with deionized water;

Embodiment 3

[0147] Embodiment 3 is basically the same as Embodiment 1, except that the backside thinning method in step 24) is wet etching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com