Formulation of colloidal titanium-oxide solutions composition for coating and printing methods, and improvement of the output and lifespan of organic p-i-n/n-i-p photovoltaic cells

A technology of colloidal solution and titanium oxide, applied in the direction of titanium oxide/hydroxide, photovoltaic power generation, titanium dioxide, etc., can solve problems such as instability and low efficiency, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

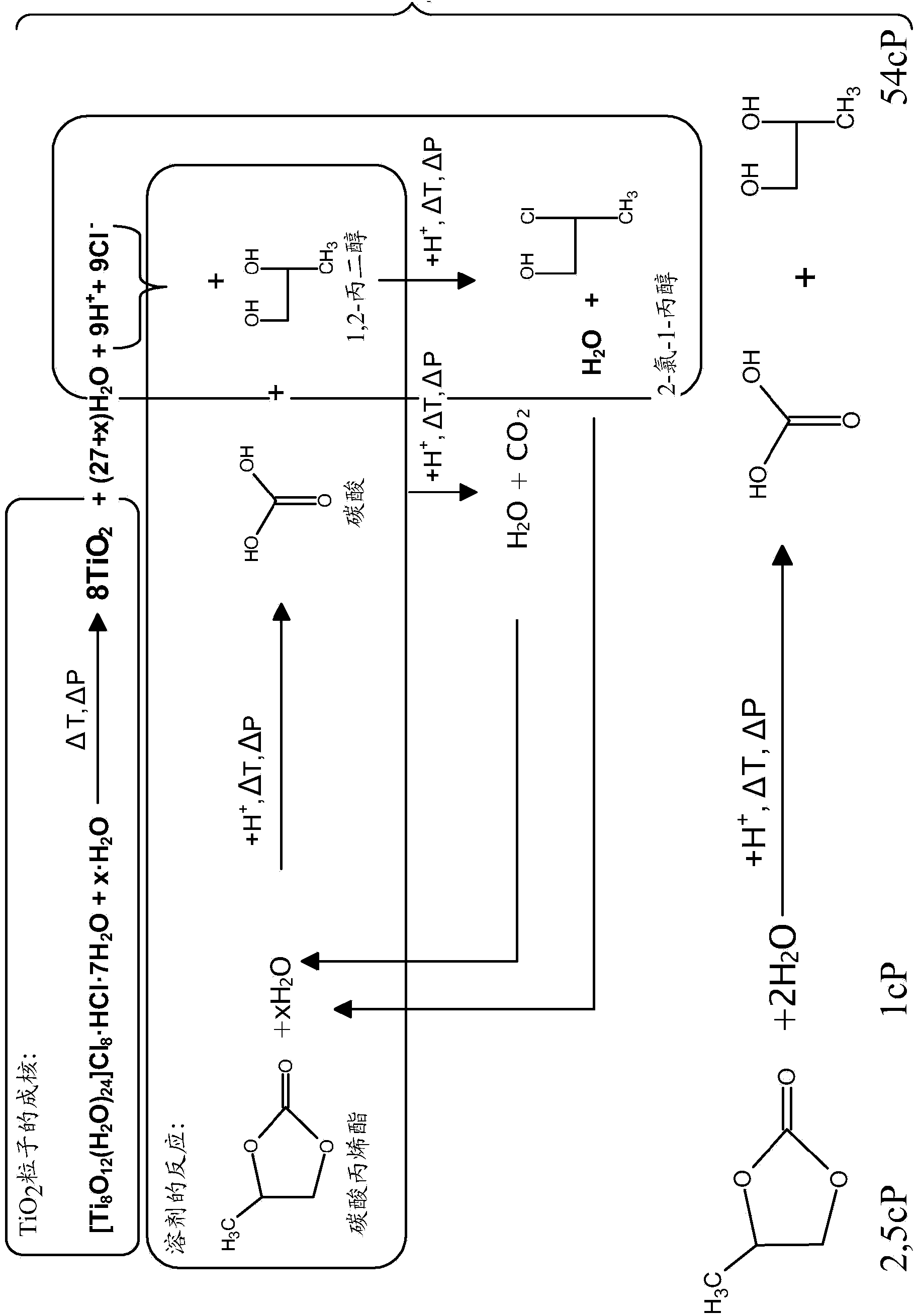

[0103] Example 1 : Preparation of TiOx / TiO2 colloidal solution

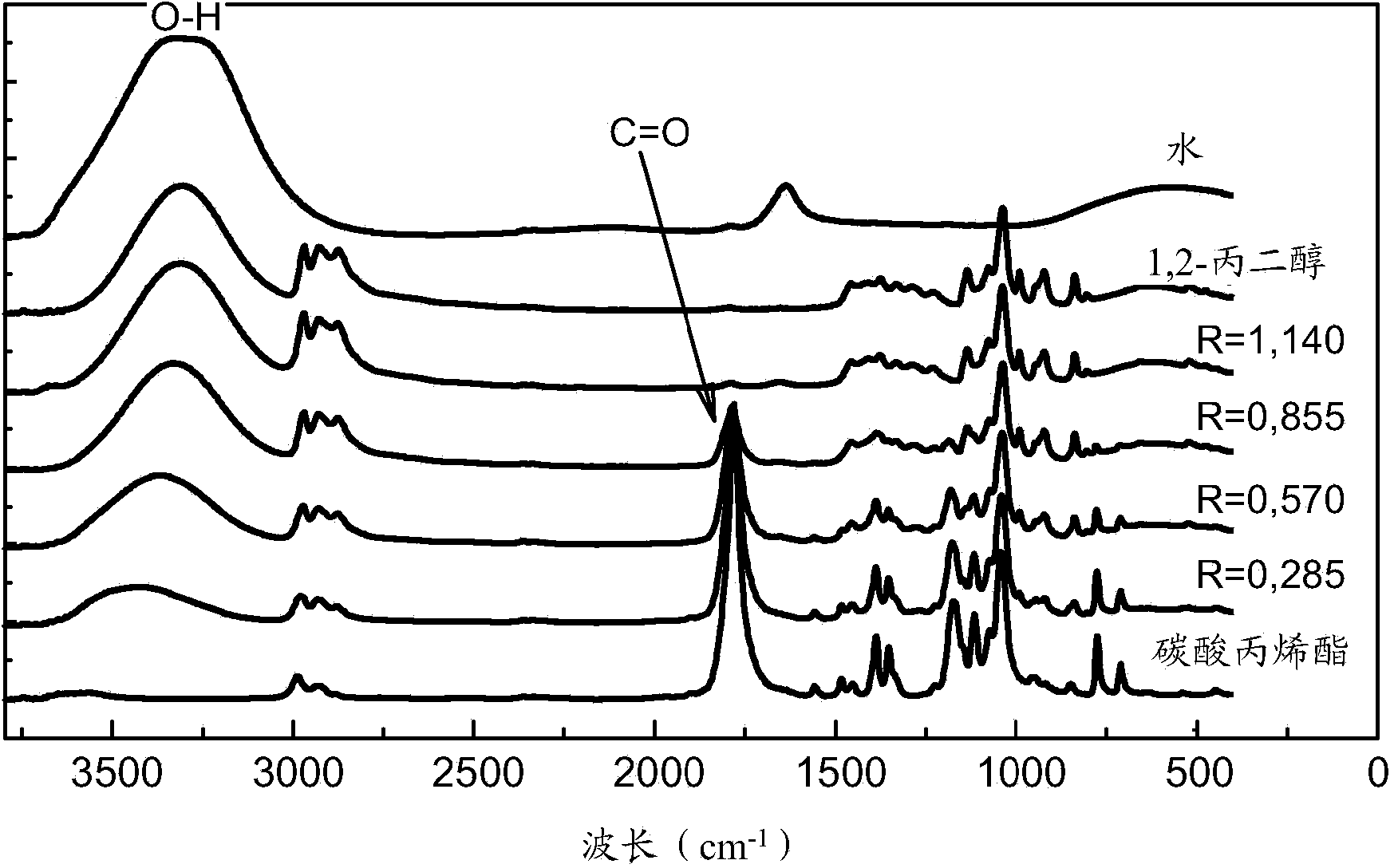

[0104] The synthesis of colloidal solutions is based on the precursor [Ti 8 o 12 (H 2 O) 24 ]Cl 8 ·HCl·7H 2 O converted to TiO 2 Nanoparticles. The reaction is carried out at low temperature (120° C.) in the presence of a binary mixture of solvents of propylene carbonate and water. The chosen solvent allows good dispersion of the precursor and makes the TiO 2 Nanoparticle nucleation. The use of a high dielectric constant solvent (water) allows to dissolve the precursor before the nucleation stage. Propylene carbonate (cyclic ester) provides support for TiO 2 The control of nucleation growth. During its reaction with the acid precursor of titanium oxide, the formation of 1,2-propanediol (or propanediol), the formation of 2-chloro-1-propanol occurs, accompanied by the consumption of water molecules and the release of carbon dioxide. Adjust the concentration of the reagent and the ratio of the solvent ...

Embodiment 2

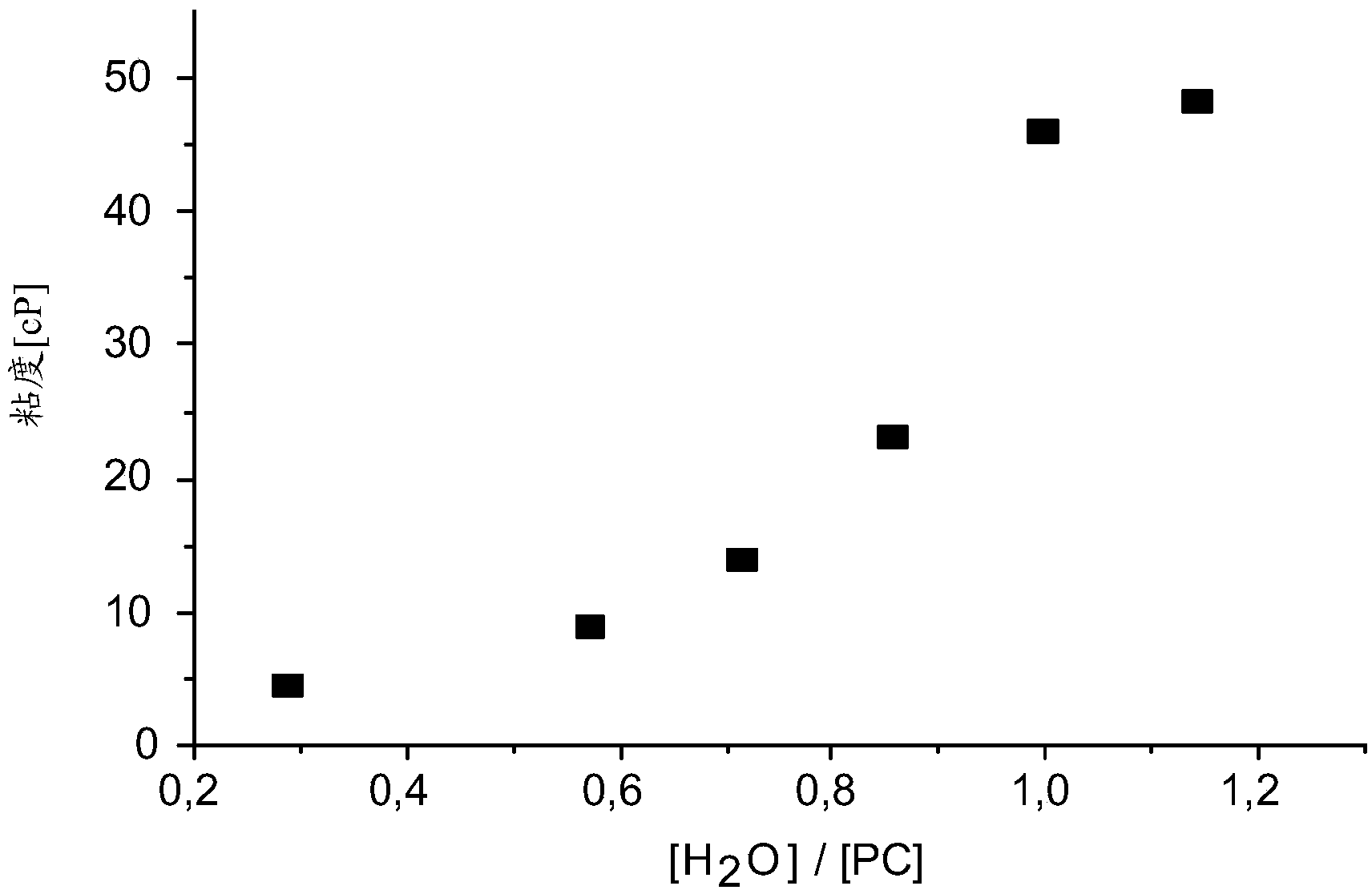

[0106] Example 2 : Control the viscosity of the colloidal solution of titanium dioxide

[0107] For the envisaged application, especially for ink-jet printing, the viscosity of the formulation of the colloidal solution can be precisely adjusted to obtain, for example, a viscosity of 8-15 cP at the printing temperature (the temperature of the printing nozzle is generally 20-80° C.) and at atmospheric pressure. viscosity.

[0108] Experimental conditions

[0109] From [Ti as a titanium precursor 8 o 12 (H 2 O) 24 ] Cl 8 ·HCl·7H 2 O (according to the international application WO2004 / 101436 (titanium aquo-oxo chloride, its method of preparation) submitted by CNRS; L.Brohan, H.Sutrisno, E.Puzenat, A.Rouet , H.Terrisse) described in the program, under controlled relative humidity (RH = 50% ~ 60%) by hydrolysis titanium concentration is usually 1.5M.L -1 TiOCl 2 The aqueous solution was carried out in the laboratory), and the colloidal solution was prepared from propylen...

Embodiment 3

[0134] Example 3 : Neutralization of colloidal solutions

[0135] The implementation of the printing technique requires controlling the pH of the colloid solution to prevent any corrosion of the printed modules. One of the steps of the method of the invention may be the hydrolysis of the titanium precursor in an aqueous medium, which hydrolysis leads to the formation of hydrochloric acid as follows:

[0136] [Ti 8 o 12 (H 2 O) 24 ] Cl 8 ·HCl·7H 2 O+x·H 2 O=>8TiO 2 +(27+x)H 2 O+9H + +9Cl -

[0137] However, when propylene carbonate is added and during heat treatment at 120 °C, propylene glycol derived from the reaction consumes HCl acid to produce neutral molecules: water and 2-chloro-1-propanol. The neutralization of the reaction can be followed by conductivity measurement. Figure 7 A trend is given for the conductivity of the colloidal solution when R=0.712 as a function of heat treatment time at T=120°C. The conductivity, which is directly proportional to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com