Preparation method of borate ion crosslinked conductive graphene paper

An ion-crosslinking, conductive graphite technology, applied in the field of graphene paper, can solve the problems of toxic chemical reagents, such as electrical conductivity, electrical conductivity not meeting requirements, damage to film structure integrity, etc., achieving easy control, close electrical conductivity, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of the conductive graphene paper of borate ion crosslinking, comprises the steps:

[0028] Step 1. Using graphite powder less than or equal to 50 μm as the carbon source, the modified Hummers method is used to prepare graphite oxide, and the graphene oxide hydrosol with a concentration of 2-5 mg / mL is obtained by ultrasonic exfoliation in deionized water.

[0029] Step 2. Add sodium hydroxide solution to the graphene oxide hydrosol prepared in step 1 to adjust the pH to 10-12, and then add boric acid according to the mass ratio of boric acid and graphene oxide at 0.1-2:50, and under electromagnetic stirring conditions Heat to 80-90°C, keep warm for 3-5 hours, then cool naturally, filter or centrifuge, wash with deionized water for several times, ultrasonically disperse in deionized water to obtain pure and evenly dispersed borate with a concentration of 1-5 mg / mL Ionically crosslinked reduced graphene oxide hydrosols. Sodium hydroxide can n...

Embodiment 1

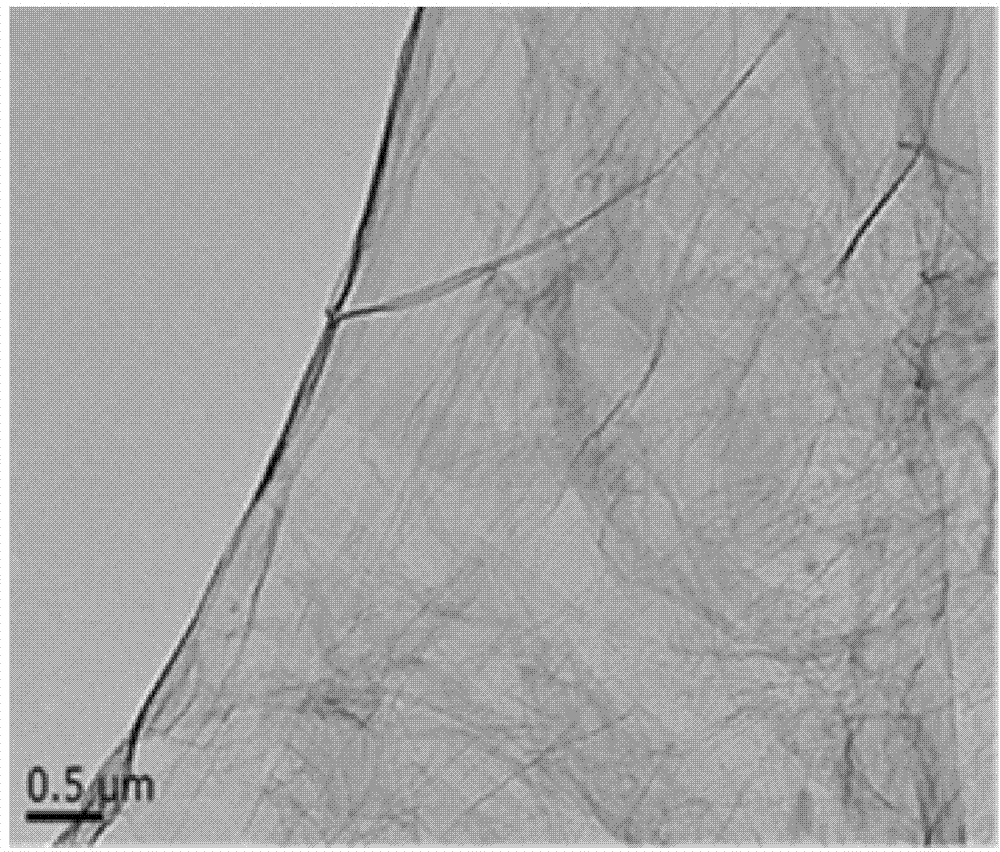

[0033] 1. Using graphite powder with a particle size of 30 μm as a carbon source, prepare graphite oxide by the above-mentioned improved Hummers method, and ultrasonically peel off in deionized water to form a uniformly dispersed 3 mg / mL graphene oxide hydrosol, such as figure 1 As shown, the obtained graphene oxide sheet has a high purity, basically a few layers overlapped together, and has an obvious wrinkled structure.

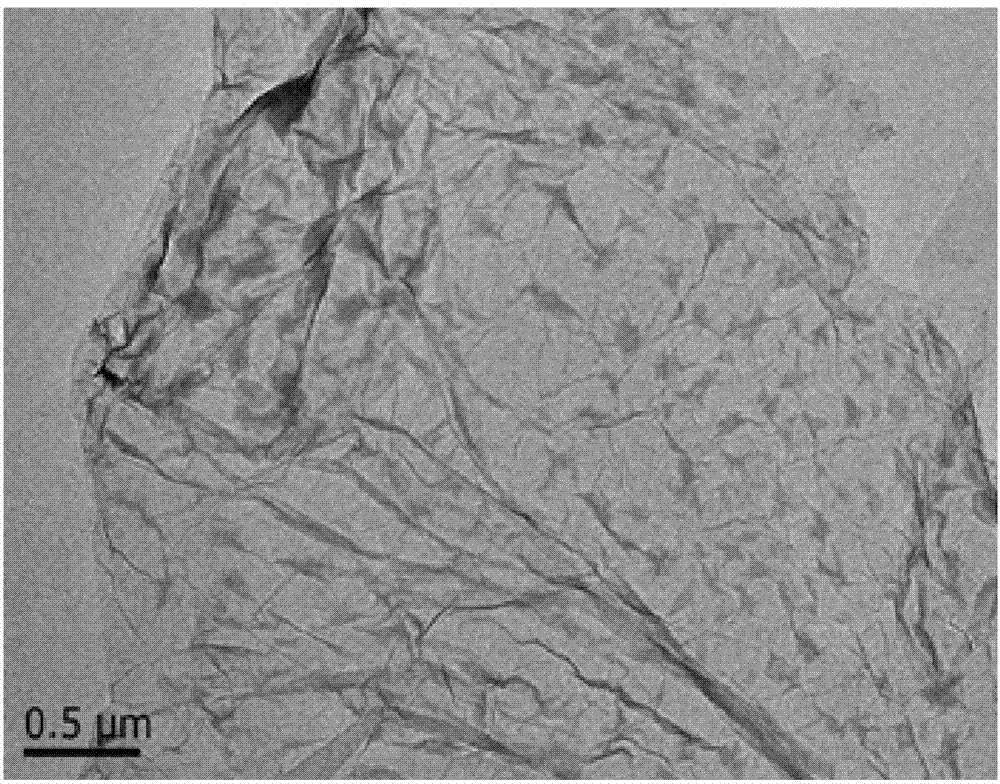

[0034]2. Take 50mL of the 3mg / mL graphene oxide hydrosol prepared above, add an appropriate amount of sodium hydroxide solution to adjust the pH to 11, then add 5mg of boric acid, heat to 90°C under the condition of electromagnetic stirring in a fume hood, and keep it warm for 5h. After natural cooling, centrifugation, deionized water washing 3 times, ultrasonic redispersion in deionized water, to obtain pure and uniformly dispersed 2mg / mL borate ion cross-linked reduced graphene oxide hydrosol, such as figure 2 As shown, it can be seen that the reduced gr...

Embodiment 2

[0039] 1. Using graphite powder with a particle size of 50 μm as a carbon source, prepare graphite oxide by the above-mentioned improved Hummers method, and ultrasonically exfoliate it in deionized water to form a uniformly dispersed 5 mg / mL graphene oxide hydrosol.

[0040] 2. Take 50mL of the 5mg / mL graphene oxide hydrosol prepared above, add an appropriate amount of sodium hydroxide solution to adjust the pH to 12, then add 10mg of boric acid, heat to 90°C under the condition of electromagnetic stirring in a fume hood, and keep it warm for 5h. After natural cooling, centrifugation, deionized water washing 3 times, ultrasonic redispersion in deionized water, to obtain pure and uniformly dispersed 5 mg / mL borate ion cross-linked reduced graphene oxide hydrosol.

[0041] 3. Take 50 mL of the borate ion-crosslinked reduced graphene oxide hydrosol prepared above, and filter layer-by-layer self-assembly through a mixed cellulose ester microporous filter membrane with a diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com