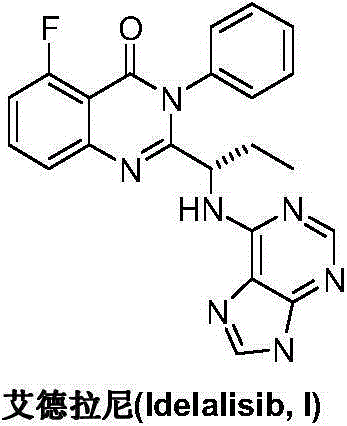

The preparation method of edranil

A technology of purine and amino group is applied in the field of preparation of medicine idelanide, which can solve problems such as environmental pollution, and achieve the effects of easy availability of raw materials, economical and environmental protection of the process, and promotion of development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

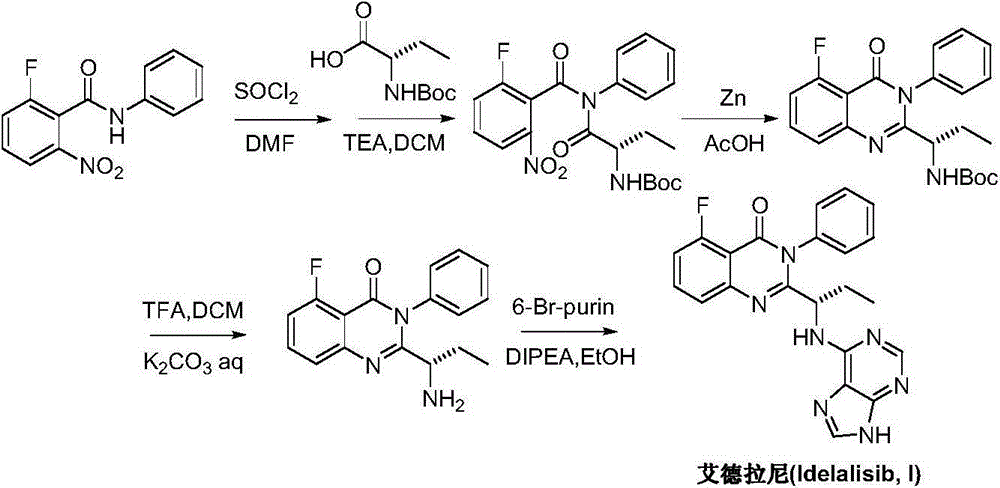

Method used

Image

Examples

Embodiment 1

[0028] Add R-2-hydroxybutyrate ethyl (II) (6.6g, 50mmol), methanesulfonyl chloride (6.3g, 55mmol) and dichloromethane 100mL into the reaction flask, cool down to 0°C, add three Ethylamine (5.6g, 55mmol) was kept at the temperature for 1 hour, raised to room temperature and stirred for 8-10 hours, and TLC detected that the reaction was complete. The reaction solution was washed successively with 10% acetic acid solution, saturated sodium bicarbonate solution and saturated brine, dried over anhydrous sodium sulfate, and concentrated under reduced pressure. The obtained oil was dissolved in 50 mL of N,N-dimethylformamide, and 6-amino -9H-purine (6.8g, 50mmol), heat up to 120°C, slowly add pyridine (4.0g, 50mmol) dropwise, continue to maintain the temperature at 120-130°C, stir for 2 hours, cool to room temperature, and pour the reaction solution into ice water, and extracted 3 times with dichloromethane, the organic phases were combined, dried over anhydrous sodium sulfate, the s...

Embodiment 2

[0030] Add R-2-hydroxybutyrate benzyl (II) (1.9g, 10mmol), p-toluenesulfonyl chloride (2.1g, 11mmol) and 25mL of dichloromethane into the reaction flask, cool down to 0°C, add di Isopropylethylamine (1.4 g, 11 mmol) was kept at the temperature for 1 hour, then raised to room temperature and stirred for 6-8 hours, and the reaction was completed as detected by TLC. The reaction solution was washed successively with 10% acetic acid solution, saturated sodium bicarbonate solution and saturated brine, dried over anhydrous sodium sulfate, and concentrated under reduced pressure. The obtained oil was dissolved in 20 mL of N,N-dimethylformamide, and 6-amino -9H-purine (1.4g, 10mmol), heat up to 120°C, slowly add pyridine (0.8g, 10mmol) dropwise, continue to maintain the temperature at 120-130°C, stir for 3 hours, cool to room temperature, and pour the reaction solution into ice water, and extracted 3 times with dichloromethane, the organic phases were combined, dried over anhydrous so...

Embodiment 3

[0032] Add S-2-(N-9H-purin-6-yl)aminobutyric acid ethyl ester (III) (5.0g, 20mmol) and 50mL of dichloromethane into the reaction flask under nitrogen atmosphere, add 2M dichloromethane dropwise at 0°C 15 mL of n-hexane solution of trimethylaluminum, slowly rise to room temperature, dropwise add 15 mL of dichloromethane solution of 2-formic acid-3-fluoroaniline (3.1 g, 20 mmol), after the drop is completed, heat up to reflux, and react for 5-6 hours , TLC detected that the reaction was complete. After cooling, the reaction solution was poured into 15% sodium hydroxide solution, extracted three times with dichloromethane, the organic phases were combined, and dried over anhydrous magnesium sulfate. After concentration, the residue was recrystallized from methanol to obtain 6.6 g of beige solid S-2-(N-9H-purin-6-yl)amino-N-(2-formic acid-3-fluorophenyl)butyramide (IV). Yield 92.2%, EI-MS m / z 359 (M+H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com