Nitrile degradation biofilm formed genetically engineered bacterium and application of genetically engineered bacterium in nitrile-containing wastewater treatment

A genetic engineering and biofilm technology, applied in the field of bioengineering, can solve problems such as poor wastewater treatment and loss of degrading bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1, the construction of genetic engineering bacterial strain Bacillus subtilis N4-pHT01-Nitr

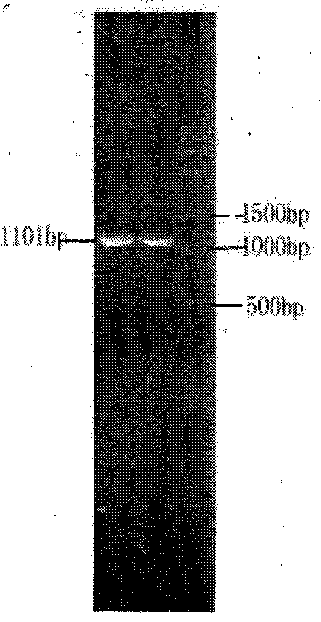

[0029] (1) PCR amplification and subcloning of the nitrilase gene in Rhodococcus rhodochrous BX2

[0030]Using the total DNA of Rhodococcus rhodochrous BX2 as a template, the primer 5'GCG was designed according to the gene sequence of the nitrilase gene and the polyclonal restriction site of Bacillus subtilis expression vector pHT01 TCTAGA ATGGTCGAATACACAAAACAATTTC 3' and 5'ATT GACGTC TCAGATGGAGGCTGTCGC3' (the underline is followed by XbaI restriction site and AatII restriction site) is a primer to amplify the gene fragment of the nitrilase gene DNA with a length of 1101bp by PCR, and the agarose gel of the nitrilase gene Electropherogram as figure 1 As shown, 1 and 2 are the PCR products of the nitrilase gene, and M is a DNA Marker of 10,000 bp, which is consistent with the expected target fragment size. After the nitrilase gene was added with an A tail, it was co...

example 2

[0042] Example 2 Genetic engineering strain Bacillus subtilis N4-pHT01-Nitr film-forming ability

[0043] The biofilm culture device is as follows: 150mL Erlenmeyer flask containing 50mL synthetic waste water, 20 polyvinyl chloride fillers and 2 glass slides. Inoculate 1 mL of Bacillus subtilis N4-pHT01-Nitr into the biofilm culture device, and use no inoculation as the control. Set up three parallels under the same conditions and take the average value. 37°C, 60r / min shaking culture, after 4 hours of culture, add 1mM / L IPTG to Bacillus subtilisN4-pHT01-Nitr, measure the biofilm formation within 48 hours.

[0044] Described synthetic wastewater is prepared according to the following ratio: glucose 0.3g / L, NH 4 Cl 0.0401g / L, KH 2 PO 4 0.0092g / L, CaCl 2 0.0107g / L, MgSO 4 0.008g / L, FeSO 4 0.00011g / L, soluble in tap water, the amount of acetonitrile added is 800mg / L.

[0045] The biofilm biomass is determined as follows: After culturing for different times, the synthetic w...

example 3

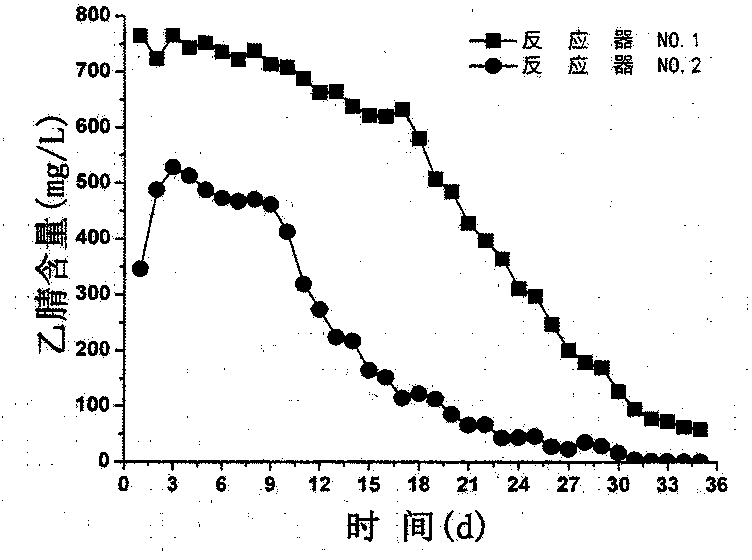

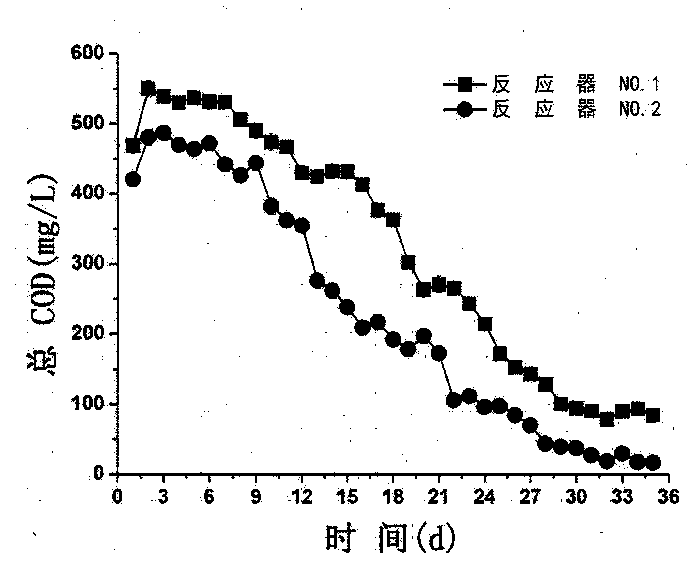

[0047] Example 3 Degradation of acetonitrile by genetically engineered bacterial strain Bacillus subtilis N4-pHT01-Nitr

[0048] (1) Tolerance and utilization of Bacillus subtilis N4-pHT01-Nitr to acetonitrile

[0049] Inoculate 1 mL (OD 600nm =1.0) The bacterial suspension of Bacillus subtilis N4-pHT01-Nitr was placed in 50mL of synthetic wastewater containing 800mg / L acetonitrile, and the synthetic wastewater without acetonitrile was inoculated as a control, and cultured on a shaking table at 37°C at 160r / min. After culturing for 4 hours, add 1mM / L IPTG to Bacillus subtilis N4-pHT01-Nitr, measure the absorbance value at 600nm within 48 hours, observe the growth status of the strain, set up three parallels under the same conditions, and take the average value; Inoculate 1mL of Bacillus subtilis N4-pHT01-Nitr bacterial suspension in 50mL inorganic salt basal medium containing 800mg / L acetonitrile, take the medium without inoculation as the control, shake at 37°C and 160r / min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com