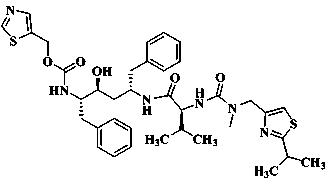

Method for preparing anti-HIV (human immunodeficiency virus) medicine ritonavir

A technology for ritonavir and medicine, which is applied in the field of preparing anti-HIV medicine ritonavir, can solve the problems of being unsuitable for large-scale industrial production, unsatisfactory for industrial production, complicated post-processing process, etc., and achieves easy separation and purification, Less pollution and environment friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

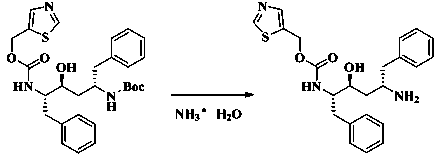

[0017] (2S,3S,5S)-5-Amino-2-( N Preparation of -((5-thiazolyl)-methoxycarbonyl)amino)-1,6-diphenyl-3-hydroxyhexane

[0018] To a clean reaction flask, add 52.6g (100mmol) of (2S,3S,5S)-5-(tert-butoxycarbonylamino)-2-( N -5-thiazolylmethoxycarbonyl) amino-1,6-diphenyl-3-hydroxyhexane and 150 mL of ethyl acetate, then add 26.2 mL of concentrated hydrochloric acid, gradually produce a slurry, and the resulting slurry Stir at 50°C for 3 h, filter, wash the filter cake twice with 40 mL of ethyl acetate, place the wet filter cake in 130 mL of ethyl acetate, add 9.4% dilute ammonia water dropwise to adjust the pH to 10.5. Take the organic phase and wash it once with 130 mL of 25% sodium chloride aqueous solution, dry it with anhydrous sodium sulfate for 3 hours, filter, and use the filtrate for later use.

Embodiment 2

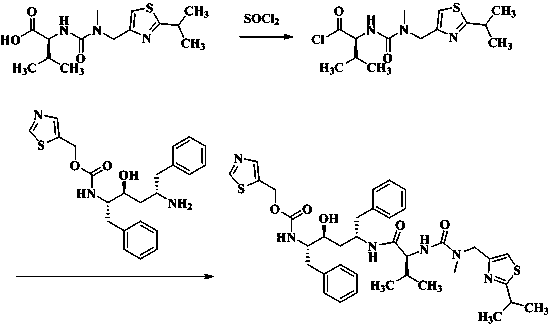

[0020] Preparation of ritonavir

[0021] Will N -[ N -methyl- N -[(2-isopropyl-4-thiazolyl)methyl]aminocarbonyl]-L-valine 62.7g (200.0mmol) was placed in a 500 mL eggplant-shaped bottle, and 200 mL ethyl acetate was added and stirred to make Dissolve it, then add 101.0 g of triethylamine and 25.2 g (212.0 mmol) of thionyl chloride, raise the temperature to 45°C to reflux the ethyl acetate, keep it warm for 3 hours, after the reaction is complete, cool down to room temperature, and filter out the triethylamine salt Salt solid, the filtrate is set aside.

[0022]The filtrate in Example 1 was slowly dropped into the system, stirred overnight, and the reaction was completed. The reaction liquid was washed successively with 10% citric acid, 10% potassium carbonate, 10% sodium chloride and purified water 250 mL×2, the water layer was discarded, and the organic phase was dried by adding anhydrous sodium sulfate for 3 h and then filtered. Then the filtrate was heated to 50°C, and...

Embodiment 3

[0024] (2S,3S,5S)-5-Amino-2-( N Preparation of -((5-thiazolyl)-methoxycarbonyl)amino)-1,6-diphenyl-3-hydroxyhexane

[0025] Into a clean reaction flask, add 36.8g (70mmol) of (2S,3S,5S)-5-(tert-butoxycarbonylamino)-2-( N -5-thiazolylmethoxycarbonyl)amino-1,6-diphenyl-3-hydroxyhexane and 110mL of acetone, then add 18.3 mL of concentrated hydrochloric acid to gradually produce a slurry, and place the resulting slurry in Stir at 50°C for 3 h, filter, wash the filter cake twice with 40 mL of acetone, place the wet filter cake in 100 mL of acetone, add 9.4% dilute ammonia water dropwise to adjust the pH to 10.5, take the organic phase for use Wash once with 120 mL of 25% sodium chloride aqueous solution, dry with anhydrous sodium sulfate for 3 hours, then filter, and the filtrate is set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com