Corrosion resistant silicone rubber material and preparation method thereof

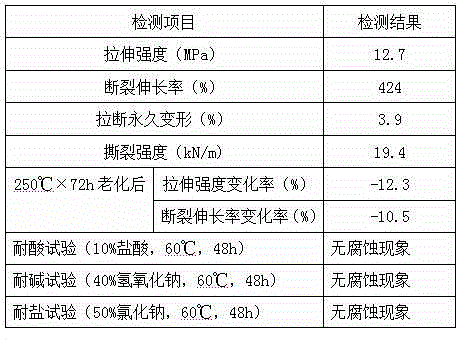

A silicone rubber, corrosion-resistant technology, used in building thermal insulation materials, building components, buildings, etc., can solve the problem that the corrosion resistance cannot meet the needs of special fields, and achieve excellent aging resistance, good physical and mechanical properties, and application range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A corrosion-resistant silicone rubber material, made of the following raw materials in weight (kg): nitrile silicone rubber 62, neoprene rubber 38, polyether ether ketone 30, fluorine resin 6, triallyl isocyanurate 2.5 , methyl vinyl silicone oil 8, polyhydroxyethyl methacrylate 12, coal tar pitch 7, diphenylmethane bismaleimide 3.5, p-tert-butyl benzoic acid zinc 2.5, dicumyl peroxide 1.5, cyclo Oxyoctyl stearate 8, acetylene carbon black 16, cadmium stearate 1.5, white clay powder 7, diisobutyl phthalate 12, N-(4-anilinophenyl)-methacrylamide 1.5, Auxiliary 4;

[0011] The preparation method of the auxiliary agent is as follows: a, take the following weight (kg) raw materials: rosin pentaerythritol ester 4.5, 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate 3, zirconium fluoride 7. Thiophosphoric acid triphenyl isocyanate 3, 4,4′-biphenyl diphenol 2, triisopropanolamine ring borate 4, 2,2-dithienyl glycolate methyl ester 2.5, bone cement powder 6 , tungsten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com