Adhesive composite diaphragm and manufacturing method thereof

A composite separator and porous membrane technology, which is applied in the direction of separators/films/diaphragms/spacers, structural parts, electrical components, etc., can solve the problems of diaphragm shrinkage or melting, battery combustion and explosion, battery short circuit, etc., to reduce heat Effects of shrinkage, improvement of production efficiency, and improvement of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

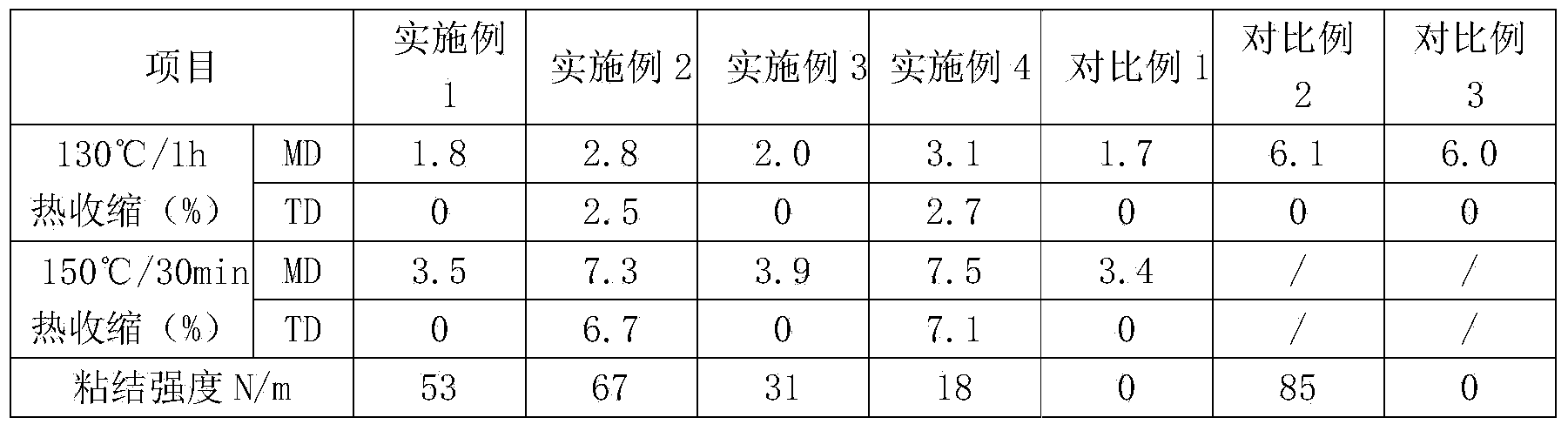

Embodiment 1

[0047]A bondable composite diaphragm, comprising a porous polypropylene membrane and a hybrid coating coated on one side of the porous polypropylene membrane, wherein the porous polypropylene membrane has a thickness of 16um, a porosity of 42%, and a coating thickness of 4um, The coating slurry used for the hybrid coating consists of a composition and deionized water; the composition includes 30 parts of polyvinylidene fluoride-hexafluoropropylene copolymer particles with a particle size of 200 nm calculated in parts by mass, and the ceramic particles are oxidized 70 parts of silicon, 2 parts of water-based adhesive polyvinyl alcohol, 4 parts of water-based adhesive polymethyl methacrylate, 1 part of carboxylate fluorine dispersant, 1 part of water-based dispersant sodium polyacrylate, high water solubility It consists of 2 parts of molecular thickener hydroxyethyl cellulose and 5 parts of wetting agent fluoroalkyl methoxy ether alcohol.

[0048] Prepare the described composit...

Embodiment 2

[0058] A bondable composite diaphragm, comprising a polyethylene porous membrane and a mixed coating coated on both sides of the polyethylene porous membrane, wherein the polyethylene porous membrane has a thickness of 5um, a porosity of 30%, and the coating thickness on both sides is uniform is 2um, and the coating slurry used for the mixed coating is composed of a composition and deionized water; the composition includes 50 parts of polyacrylonitrile particles with a particle diameter of 1um calculated in parts by mass, and 50 parts of ceramic particles of aluminum sesquioxide , water-based adhesive styrene-butadiene latex 5 parts, water-based adhesive polybutylmethacrylate 3 parts, water-based dispersant sulfonate fluorine dispersant 0.5 part, water-based dispersant potassium polyacrylate 0.5 part, water-soluble polymer It consists of 3 parts of sodium carboxymethyl cellulose as a thickening agent and 1 part of wetting agent fluoroalkyl ethoxy ether alcohol.

[0059] Prepar...

Embodiment 3

[0069] A bondable composite diaphragm, comprising a polypropylene / polyethylene / polypropylene composite porous film and a mixed coating coated on one side of the polypropylene / polyethylene / polypropylene composite porous film, wherein the polypropylene / polyethylene / polypropylene The thickness of the polypropylene composite porous film is 20um, the porosity is 39%, and the coating thickness is 5um. The coating slurry used for the mixed coating is composed of composition and deionized water; 20 parts of 2um polyethylene oxide particles, 80 parts of ceramic particles boehmite, 5 parts of water-based adhesive ethylene-vinyl acetate copolymer, 3 parts of water-based dispersant sodium polyacrylate, water-soluble polymer thickener polyacrylamide 5 parts, and 3 parts of wetting agent alkylphenol polyoxyethylene ether.

[0070] Prepare the described composite membrane with bonding function; including the following preparation steps:

[0071] (1) Add 3 parts of water-soluble polymer thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com