Acrylamide copolymer oil-displacing agent containing phenothiazine and oleamide structures and synthesis method

A technology of acrylamide copolymer and acrylamide copolymerization, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of poor temperature resistance, salt resistance and shear dilution resistance, complicated operation and high cost of oil displacement agent problem, to achieve the effect of enhanced oil recovery, simple preparation method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment one monomer N-allyl phenothiazine (NADP)

[0029] (1) 19.9 parts of phenothiazine and 50 parts of tetrahydrofuran were dropped into Reactor 1, and stirred at room temperature until completely dissolved;

[0030] (2) Slowly add 36 parts of NaH to reactor 1, during the reaction, the system temperature is controlled below 10°C;

[0031] (3) filter the product obtained in reactor 1, remove the solid phase to obtain a liquid phase, and transfer the liquid phase to reactor 2;

[0032] (4) Slowly add 144 parts of allyl bromide dropwise to the reactor 2, during the dropwise addition, the temperature of the system is controlled below 10°C;

[0033] (5) After the dropwise addition is completed, the reactor is placed at room temperature, and the reaction is continued for 5 hours to obtain the crude product of the target product;

[0034] (6) Excess raw materials and solvent were distilled off under reduced pressure to obtain light yellow solid N-allyl...

Embodiment 6

[0035] The preparation of embodiment two tetrapolymer AM / AA / NADP / CON

Embodiment 7

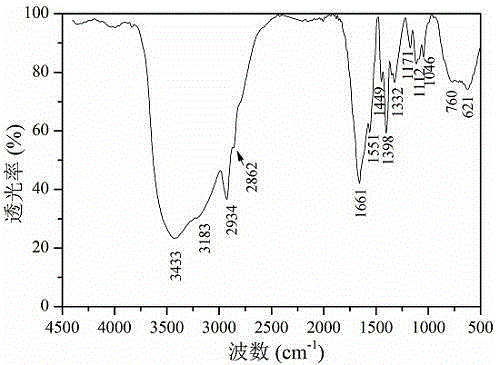

[0063] Structural Characterization of Embodiment Three Quaternary Polymer AM / AA / NADP / CON

[0064] The sample obtained in Test Example 2 in Example 2 was subjected to structural analysis, and the technical method used in the analysis was infrared spectroscopy. After the above samples were purified many times, they were characterized by infrared spectroscopy by using the KBr tablet method, and the results were as follows: figure 1 . From figure 1 It can be seen that the infrared spectrum contains -NH 2 ,—OH,C—O,—CH 2 - Absorption peaks of functional groups such as C=O and benzene ring, the above structure is consistent with the target copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com