Method for efficiently expressing phospholipase

A high-efficiency expression, phospholipase technology, applied in the field of enzyme engineering, can solve the problems of limited enzyme sources and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

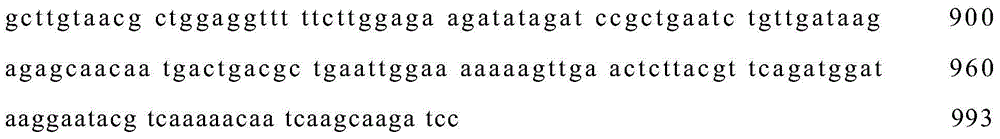

[0018] Embodiment 1: Cloning expression and fermentation process of phospholipase A1 in Pichia pastoris.

[0019] Purify the DNA fragment encoding phospholipase A1 amplified by PCR and digest the plasmid pPIC9K with EcoRI / NotI, and then ligate to obtain pPIC9K-PLA1. After the enzyme digestion verifies that the size of the plasmid fragment is correct, perform gene sequencing, and the recombinant plasmid SacI digests linearly. After transformation into Pichia pastoris cells, pick the transformants grown on the MD plate, spot on the YPD / G418 plate to screen for multi-copy transformants, and the G418 concentration selection gradient is 0.25mg / mL, 0.5mg / mL, 1.0mg / mL, and 2.0mg / mL recombinants were named P. pastorisKM71 / pPIC9K-PLA1.

Embodiment 2

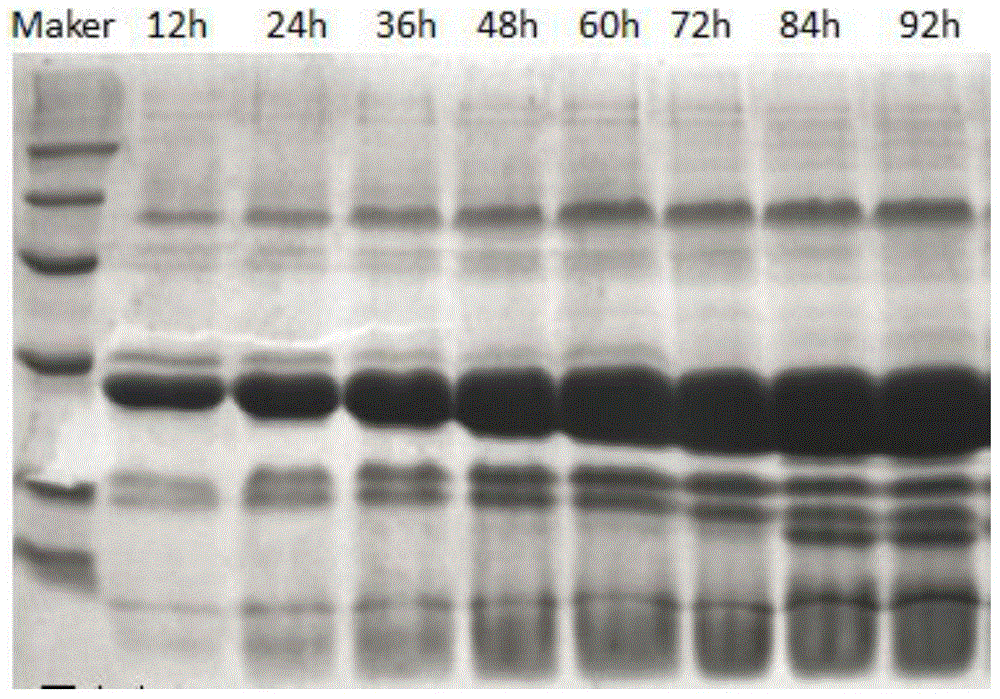

[0020] Embodiment 2: 3L tank fermentation culture of recombinant P. pastoris KM71 / pPIC9K-PLA1 bacterial strain.

[0021] Draw 200μl of the glycerol tube bacteria solution and inoculate it into a 500mL Erlenmeyer flask containing 100mL of seed medium, cultivate at 30°C and 200r / min for 24h, then connect the above-mentioned culture solution to a 3L fermenter with a liquid volume of 0.9L, and add 25% Ammonia water controls the pH to 5, the culture temperature is 30°C, and the dissolved oxygen is maintained at about 30% by coupling with the stirring speed and adjusting the ventilation rate. When the dissolved oxygen rises rapidly, it indicates that the glycerol in the medium has been exhausted, and the feeding volume ratio is started. 50% glycerol feeding solution, when the cell concentration reaches OD 600When = 100, stop feeding, keep the substrate depleted state for about 1 hour, start the induction phase, set the induction temperature at 28°C, add 0.5% volume of methanol in th...

Embodiment 3

[0023] Example 3: Recombinant phospholipase A1 is applied to the enzymatic degumming of soybean oil crude oil, and the content of phosphorus is measured according to GB / T 5537-2008.

[0024] Take 100g of soybean oil in a 250mL Erlenmeyer flask, heat it in a water bath to 80°C, then add 120μL of 45% citric acid, then homogenize at 1000rpm for 1min, stir in an 80°C water bath at 500rpm for 20min, cool to 55°C, add 4% after cooling Adjust the sodium hydroxide solution to pH 5.0, add 2mL of ultrapure water, and then add 100μL of enzyme solution to react, 55°C, 500rpm, stir for different times to sample, then keep the sample at 90°C for 15min, then centrifuge to take The clear liquid oil, the phospholipid in the oil is burned to become phosphorus pentoxide, which is turned into phosphoric acid by hot hydrochloric acid, and sodium phosphomolybdate is formed when it encounters sodium molybdate, which is reduced to molybdenum blue with hydrazine sulfate, and is measured at the waveleng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com