Preparation method of magnetic metal organic framework material and application of magnetic metal organic framework material

A technology of organic framework and magnetic metal, which is applied in the field of material chemistry and sample pretreatment, can solve the problems of cumbersome preparation steps and long time, and achieve the effect of simple preparation method, low detection limit and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Fe 3 o 4 Preparation of / MIL-101(Fe):

[0030] Step (1). Preparation of Fe 3 o 4 Nanoparticles:

[0031] FeCl 3 ·6H 2 O (2.35g) and ferrous salt FeCl 2 4H 2 O (0.86 g) was dissolved in 80 mL deionized water under N 2 Under protected conditions, heat in a water bath at 80°C, then slowly drop 30 mL of 5% ammonia water into the above mixture to adjust the pH value to greater than 9, and stir for 1 h. The product is washed with deionized water until the pH of the filtrate is neutral to obtain the nanomagnetic material Fe 3 o 4 ;

[0032] Step (2). Preparation of Fe 3 o 4 / MIL-101(Fe) composite material

[0033] Get the nano-magnetic material Fe of 4 mmol step (1) gained 3 o 4 Sonicate for 10 min and disperse into 100 mL deionized water to obtain uniform Fe 3 o 4 Nanoparticle dispersion; take 5 mL dispersion (containing 0.2 mmol nanomagnetic material Fe 3 o 4 ) for centrifugation for 5 min, discard the supernatant, and add the precipitate to 33...

Embodiment 2

[0034] Example 2: Fe 3 o 4 The preparation of nanoparticles is the same as described in Example 1 step (1); the preparation of MIL-101 (Fe) material is the same as described in Example 1 step (2), except that Fe is not added 3 o 4 .

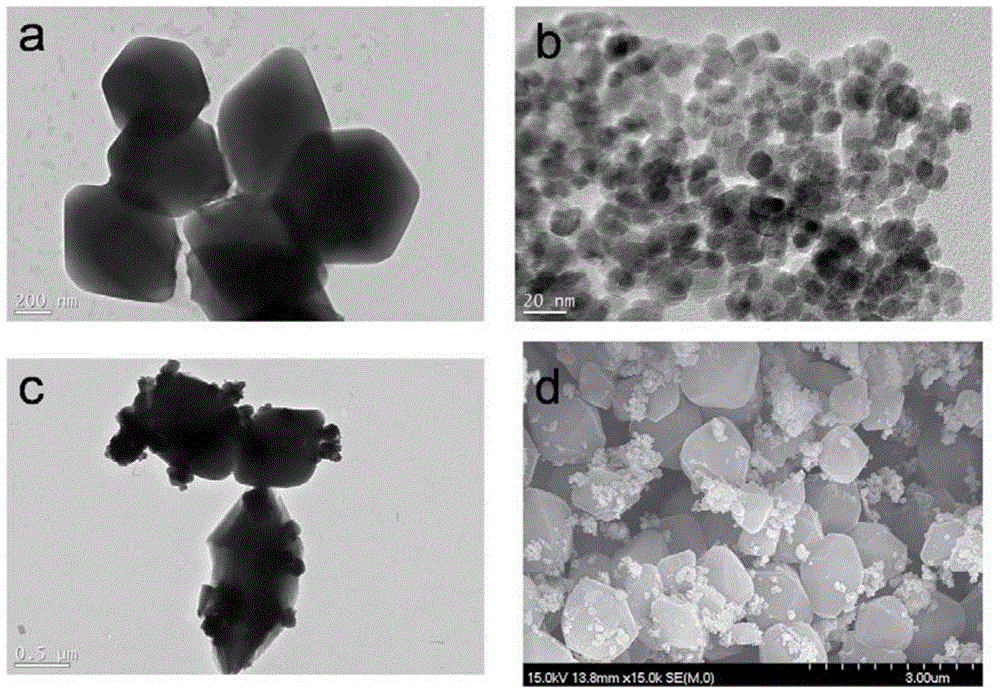

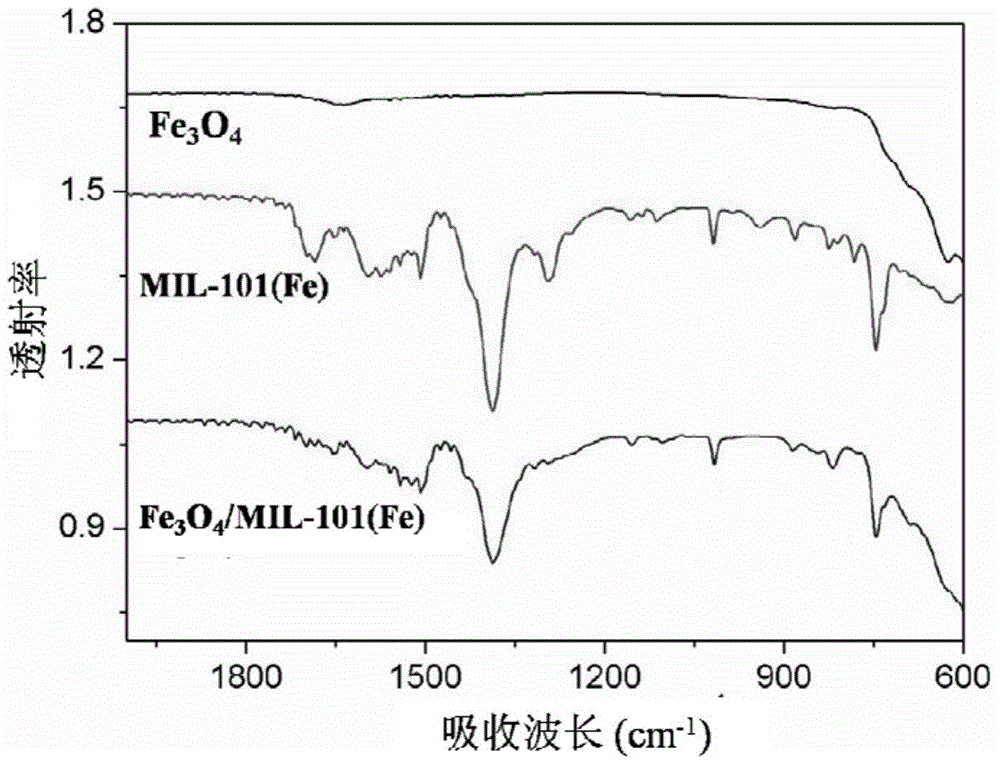

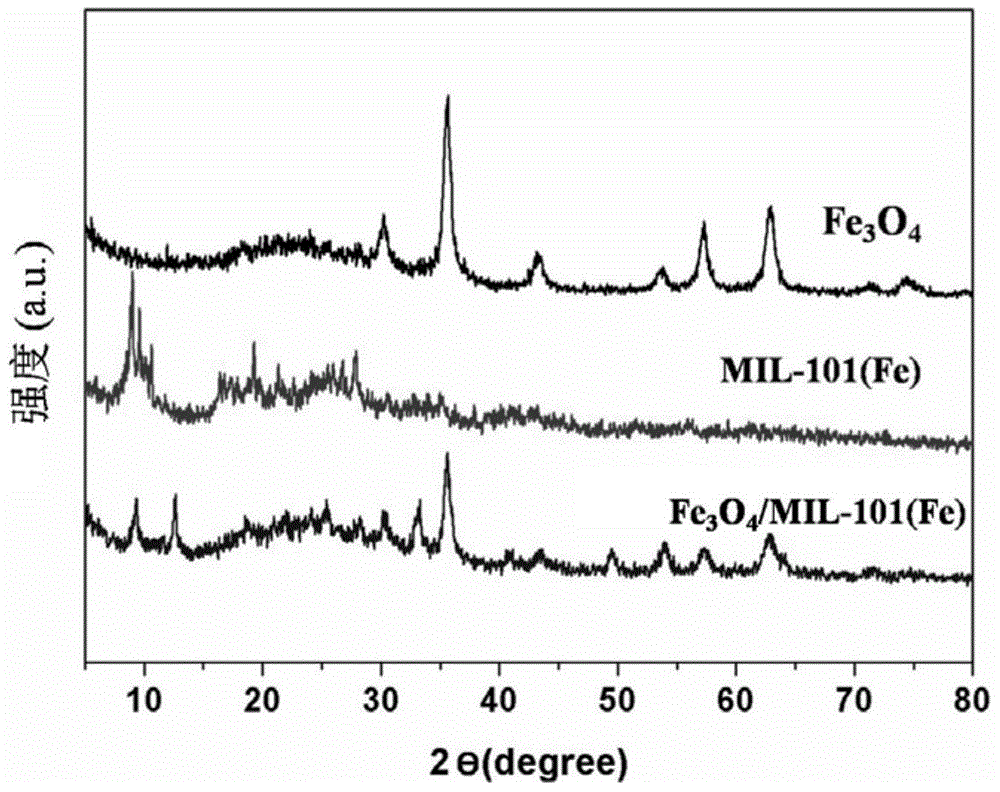

[0035] Figure 1~4 Be the Fe that obtains according to embodiment 1~2 of the present invention 3 o 4 / MIL-101(Fe) and MIL-101(Fe), Fe 3 o 4 Electron micrographs, infrared spectra, XRD and hysteresis loop spectra.

[0036] figure 1 a is MIL-101 (Fe) crystal material; figure 1 b is Fe prepared by co-precipitation method 3 o 4 Particles, whose size distribution is uniform, are about 20 nm; by figure 1 c shows that the Fe prepared by this method 3 o 4 / MIL-101(Fe) composite material is Fe 3 o 4 Attached to the surface of MIL-101(Fe) crystals, did not change the morphology of MIL-101(Fe); by figure 1 d, it can be seen that the size of the composite material is uniform.

[0037] Depend on figure 2 It can be seen that Fe 3 o 4 No c...

Embodiment 3

[0040] Example 3: Fe 3 o 4 / Characterization of extraction performance of MIL-101(Fe)

[0041] (1). Fe 3 o 4 / MIL-101(Fe) and Fe 3 o 4 Comparison of adsorption performance

[0042] Disperse 20 mg of magnetic material in a sample solution (3 mL) containing six kinds of organophosphorus, including Dichlorvos, Methamidophos, Dimethoate, Parathion-methyl, Malathion (malathion) and parathion (parathion), organic phosphorus concentrations are 20 ng / mL. Adjust the ionic strength to 5% w / v with NaCl, shake for 40 min, so that the organic phosphorus is adsorbed on the surface of the magnetic material; after the adsorption is completed, the magnetic material combined with the organic phosphorus is separated from the sample solution under the action of an external magnetic field; finally , add 200 μL of acetone for ultrasonic desorption for 10 min, desorb twice, combine the desorbed solution, dry it, reconstitute it with 150 μL of ethyl acetate, and measure it with a gas chromatog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Linear | aaaaa | aaaaa |

| Correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com