Method for preparing cuprous oxide nanometer wire by utilizing plant phenolic acid

A plant phenolic acid, cuprous oxide technology, applied in copper oxide/copper hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of impure composition of cuprous oxide nanowires and high raw material cost , high toxicity, etc., to achieve the effect of being suitable for large-scale production, simple process, and pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 4.62g protocatechuic acid (molecular weight=154.12), add 1000mL deionized water, after dissolving, utilize the NaOH aqueous solution of concentration 2mol / L to adjust the pH=11 of solution, the solution is heated to 75 ℃ and keep this temperature at 100 Stir at a speed of ~200rpm for 60 minutes; then add 600mL of 0.05mol / L copper sulfate aqueous solution to the aqueous solution of protocatechuic acid at a rate of 10mL / min, and keep the pH = 11; ℃ temperature, 100-200rpm stirring speed for 60 minutes, and then centrifuge at 4000-5000rpm to separate the solid sediment; after the sediment was washed with deionized water and ethanol, it was vacuum-dried at 60℃ for 24 hours to obtain cuprous oxide single crystal nanowires.

[0033] The cuprous oxide single crystal nanowire has a diameter of about 55-67 nanometers and a length of about 5.5-6.2 microns.

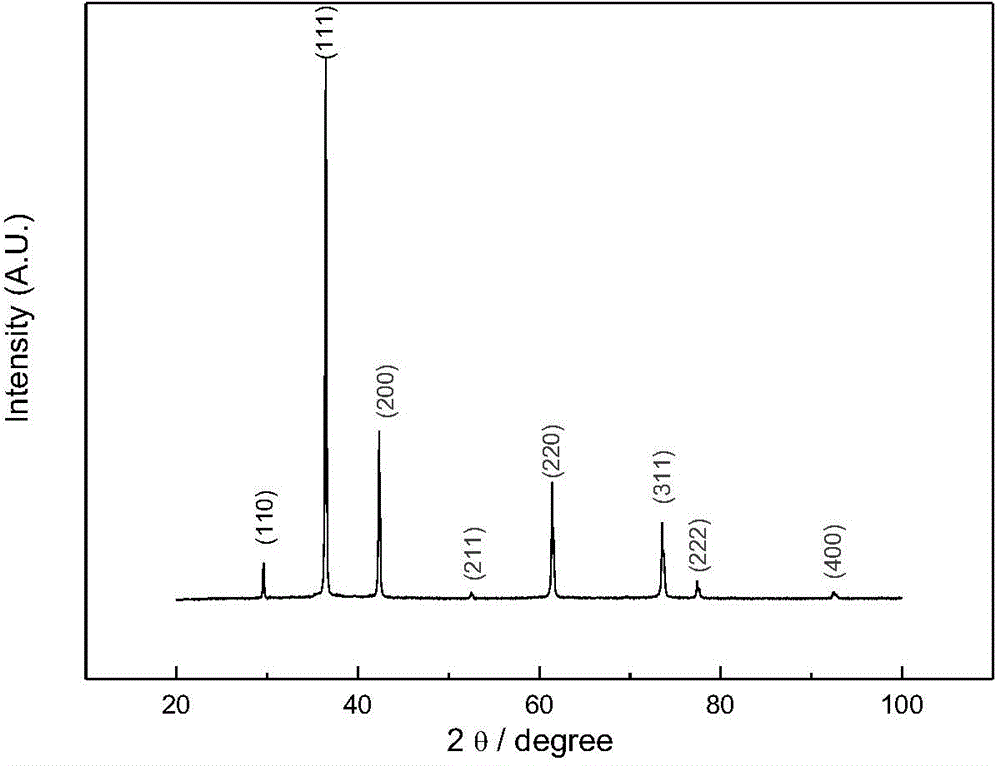

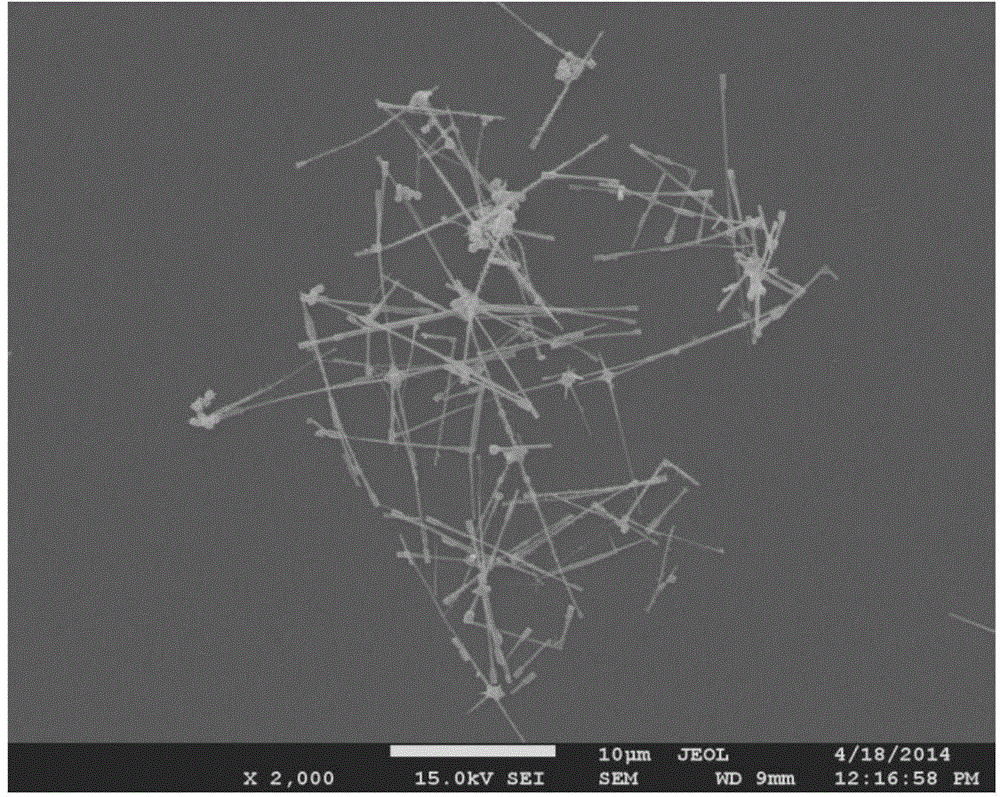

[0034] figure 1 and figure 2 It is the XRD pattern and the SEM pattern of the cuprous oxide nanowire prepared by ...

Embodiment 2

[0036] Weigh 2.55g of gallic acid (molecular weight = 170.12), add 800mL of deionized water, after dissolving, use 2mol / L KOH aqueous solution to adjust the pH of the solution to 10, heat the solution to 85°C and maintain the temperature at a speed of 100-200rpm Stir for 2 hours; then add 400 mL of copper chloride solution with a concentration of 0.5 mol / L into the gallic acid aqueous solution at a rate of 5 mL / min, and keep the pH=10; React at a stirring speed of 100-200rpm for 2 hours, and then centrifuge at a speed of 7000-8000rpm to separate the solid sediment; after the sediment is washed with deionized water and ethanol, it is vacuum-dried at 80°C for 36 hours to obtain a cuprous oxide single crystal nanowire .

[0037] The cuprous oxide single crystal nanowire has a diameter of about 93-97 nanometers and a length of about 12.9-14.6 microns.

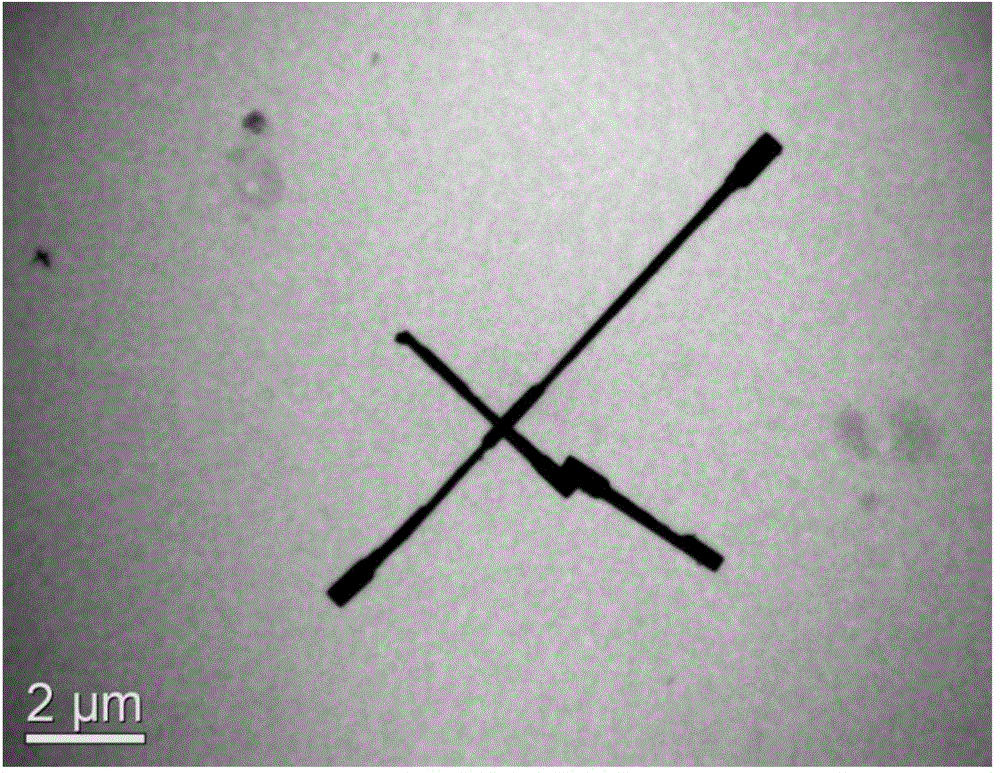

[0038] image 3 and Figure 4 It is the TEM image and the electron diffraction image of the cuprous oxide nanowire prepared by...

Embodiment 3

[0040]Weigh 8.51g of gallic acid, add 1000mL of deionized water, after dissolving, use 3mol / L KOH aqueous solution to adjust the pH of the solution to 7, heat the solution to 60°C and keep stirring at a speed of 100-200rpm for 30 minutes; then mix 0.2 Add 1000mL of mol / L copper nitrate solution into the gallic acid aqueous solution at a rate of 8mL / min, and keep the pH = 7; after mixing, the solution continues to react at a temperature of 60°C and a stirring speed of 100-200rpm for 30 minutes , filtered, and the precipitate was washed with deionized water and ethanol, and vacuum-dried at 70° C. for 24 hours to obtain cuprous oxide single crystal nanowires.

[0041] The cuprous oxide single crystal nanowire has a diameter of about 72-77 nanometers and a length of about 11.7-13 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com