Microbial flocculant proteus vulgaris and application thereof in cane juice clarification

A microbial flocculant, Proteus vulgaris technology, applied in the field of microbial flocculant Proteus vulgaris N-25 and its application in sugarcane juice clarification, can solve the problem of difficult degradation of polyacrylamide, and achieve a short separation and purification cycle , Wide range of sources, fast growth and metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

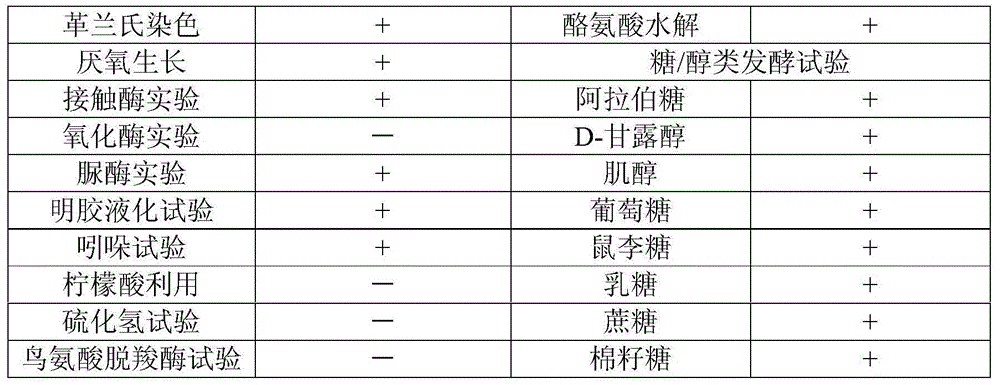

[0034] Take 1mL of activated sludge sample from a sewage treatment plant in Guangzhou and dilute to 10 -1 ~10 -7 After different volume concentration gradients, take 10 -4 、10 -5 、10 -6 、10 -7 Sludge microorganisms were inoculated on agar medium by the spread plate method. After inoculation, it was cultured in a constant temperature incubator at 30°C for 2 days, and various microbial colonies were isolated on the plate medium. Colonies were picked by streaking on plates and placed on petri dishes for expansion. Repeat the above steps to obtain microorganisms with different colony shapes after 5 times of separation and purification, inoculate them on the slant medium, and store them in a refrigerator at 4°C. Then the purified strains were put into 50ml screening medium respectively, placed in shake flasks at 35°C and 150r / min and cultured for 3 days, and the flocculation activity of the obtained culture medium was initially determined by the following method.

[0035] In t...

Embodiment 2

[0042] Inoculate the microbial flocculant Proteus vulgaris N-25 obtained through screening in Example 1 into a test tube containing seed culture solution and incubate at 30° C. for 24 hours. Then it was inoculated into the fermentation broth for fermentation and culture, the fermentation temperature was 35° C., the rotation speed of the shaker was 150 rpm, and the fermentation time was 4 days. The fermentation broth was centrifuged at 6000r / min for 30min, and the supernatant was taken as microbial flocculant.

Embodiment 3

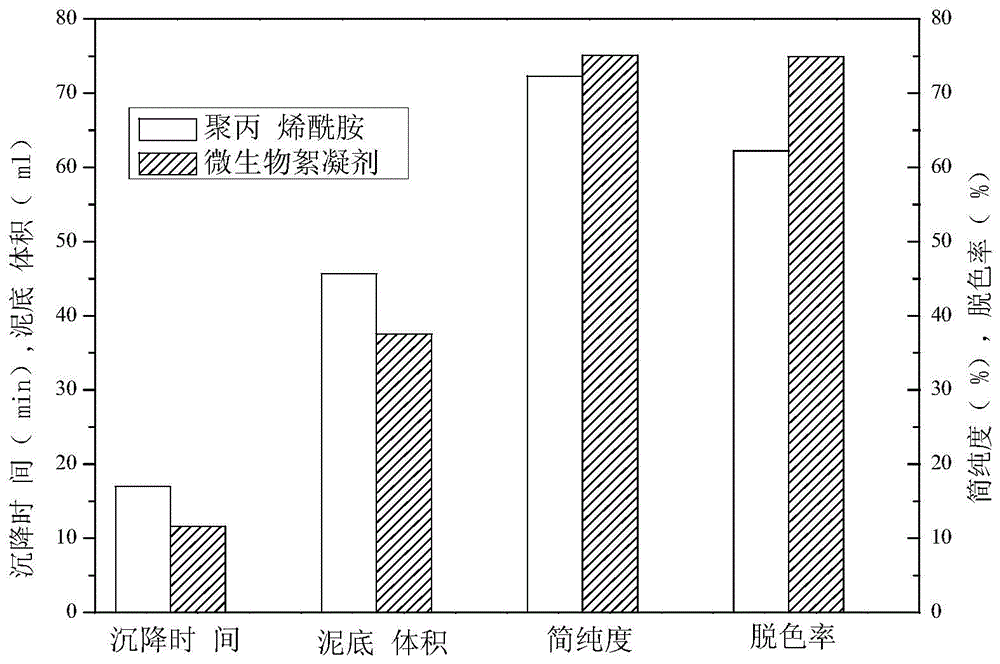

[0044] Take 100ml of sugarcane mixed juice, add 50μL of phosphoric acid with a mass fraction of 85%, adjust the pH to 6.8 with milk of lime, heat and stir to 60°C, and keep warm for 2min. Add sulfite with a mass fraction of 6%, and the amount of sulfur fumigation is 1.8g / L, then use milk of lime to neutralize the pH to 7.1, heat it to 100°C for the second time, and quickly add 2ml of microbial flocculant or 0.1% polyacrylamide 0.2ml, stir well and let stand. Record the time required to settle 50ml. After 30 minutes, measure the volume of the mud bottom, take the supernatant and filter it with a 0.45 μm microporous membrane, measure the light conversion, refraction and absorbance at 560 nm of the filtrate, and calculate the simple purity and color value of the sugarcane juice. The determination and calculation of simple purity and color value are carried out according to the method of "analysis method of sugarcane sugar chemical management", and the results are as follows: fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com