Novel method for synthesizing nano-hollow silicon sphere supported noble metal catalyst by micro-emulsion method

A technology of microemulsion method and hollow silicon, which is applied in the field of technology, can solve the problems of low photon quantum efficiency and limited application, and achieve the effect of increasing specific surface area, low investment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

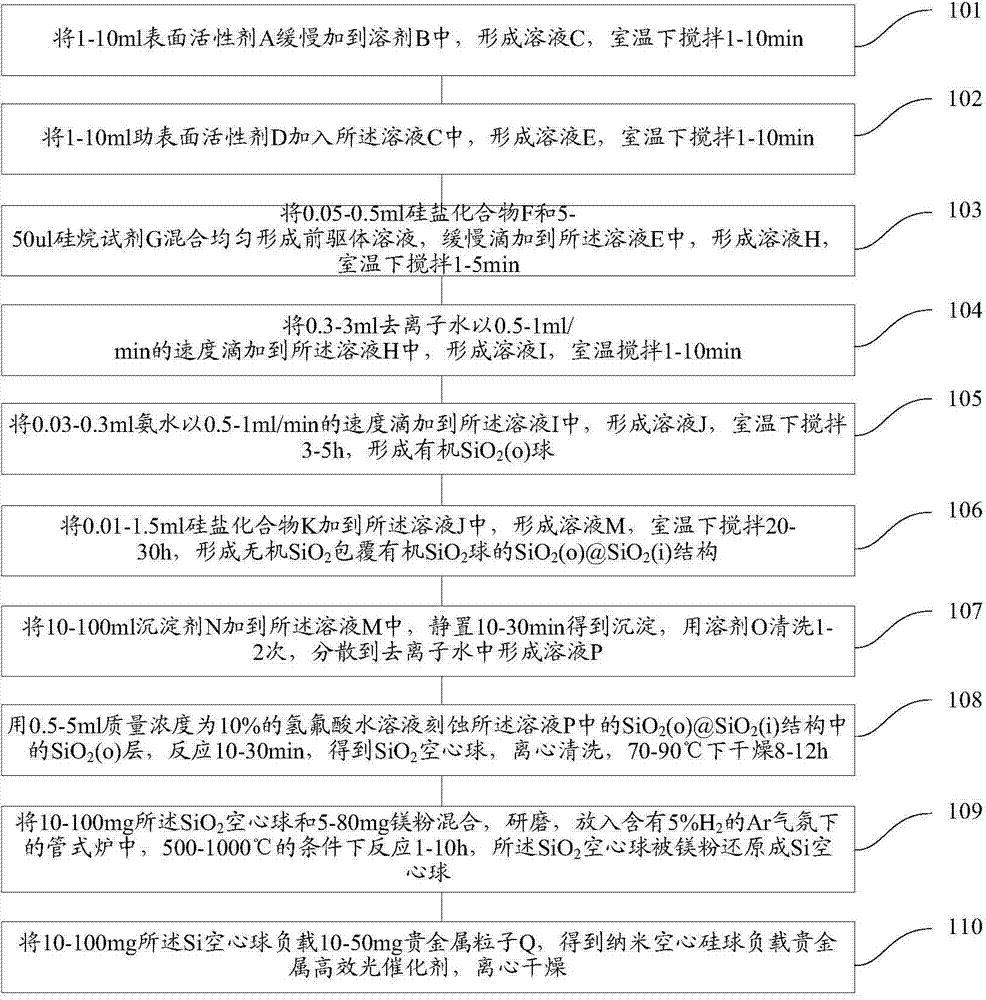

Method used

Image

Examples

Embodiment 1

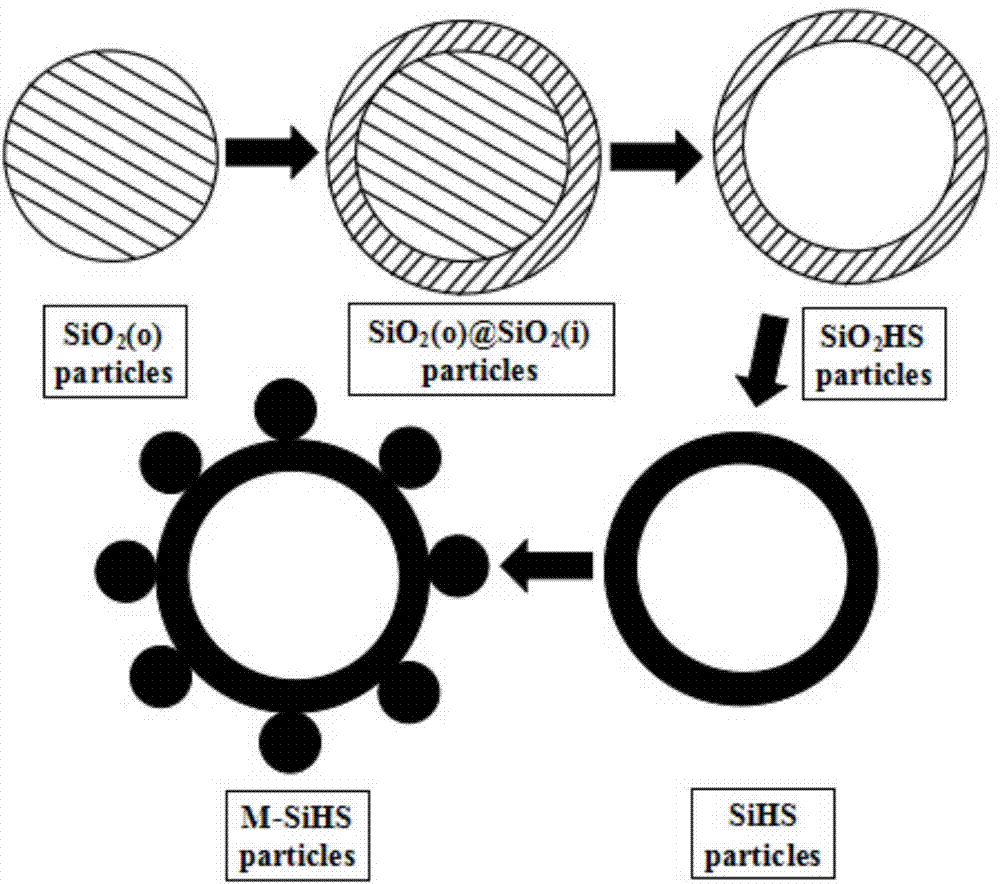

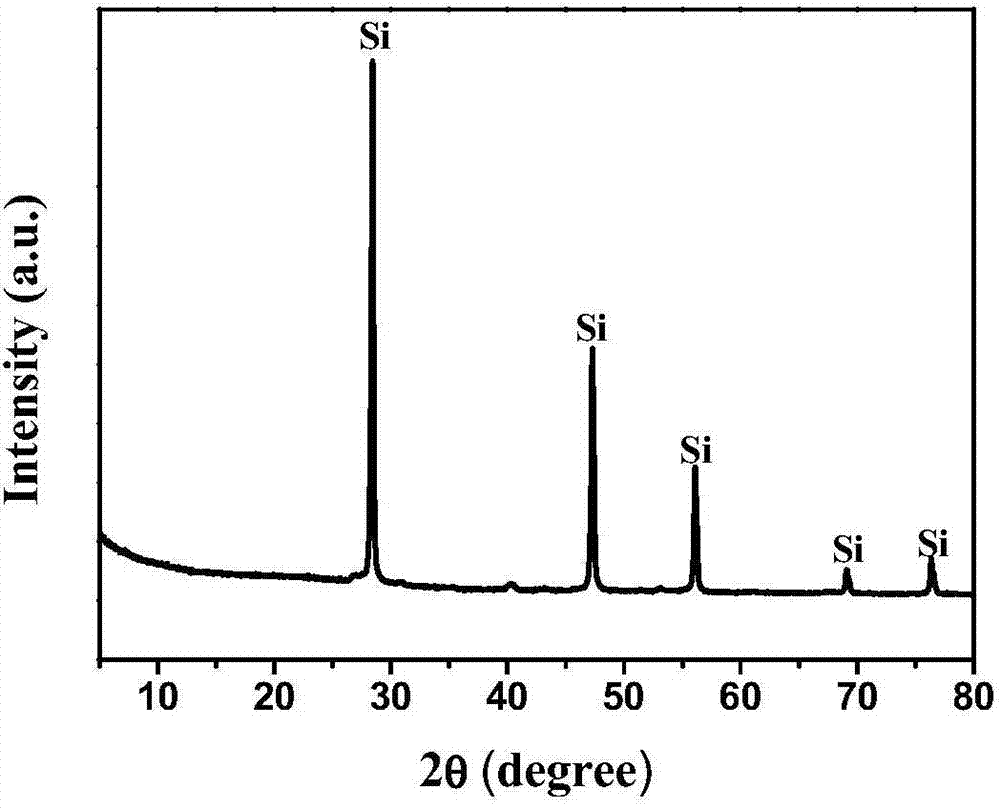

[0051] (1) Slowly add 1ml of octylphenol polyoxyethylene ether to 20ml of n-hexane, and stir for 1min at room temperature; add 1ml of n-butanol to the above solution, and stir for 1min at room temperature, at this time a microemulsion system is formed; 0.3 Mix ml butyl silicate and 30ul octadecyltrimethyloxysilane to form a precursor solution, slowly add dropwise to the above solution, stir at room temperature for 3min; add 3ml deionized water dropwise at a speed of 0.5ml / min Add to the above solution, stir at room temperature for 10min; drop 0.03ml of ammonia water into the above solution at a rate of 0.5ml / min, stir at room temperature for 5h, and form organic SiO 2 (o) Ball.

[0052] (2) Add 0.8ml butyl silicate to the above solution, stir at room temperature for 25h to form inorganic SiO 2 Coated organic SiO 2 The structure of the ball is SiO 2 (o)SiO 2 (i) Structure.

[0053] (3) Add 50ml of diacetyl to the above solution, let it stand for 20min to obtain a precipita...

Embodiment 2

[0057] (1) 10ml of high-carbon fatty alcohol polyoxyethylene ether is slowly added to 50ml of n-hexane, and stirred at room temperature for 10min; 10ml of n-octanol is added to the above solution, and stirred at room temperature for 10min, at which point a microemulsion system is formed; 0.3ml ethyl silicate and 30ul hexamethyloxydisilane were mixed uniformly to form a precursor solution, slowly added dropwise to the above solution, and stirred at room temperature for 3 minutes; 1.5ml deionized water was added dropwise to the above mentioned solution, stirred at room temperature for 5 minutes; 0.15ml of ammonia water was added dropwise to the above solution at a rate of 0.75ml / min, and stirred at room temperature for 4 hours to form organic SiO 2 (o) the ball;

[0058] (2) Add 0.8ml ethyl silicate to the above solution, stir at room temperature for 25h to form inorganic SiO 2 Coated organic SiO 2 The structure of the ball is SiO 2 (o)SiO 2 (i) structure;

[0059] (3) Add ...

Embodiment 3

[0063](1) Slowly add 5ml of polyethylene glycol p-isooctylphenyl ether to 50ml of n-hexane, and stir at room temperature for 5 minutes; add 5ml of isooctyl alcohol to the above solution, and stir at room temperature for 5 minutes, at which point a microemulsion is formed system; mix 0.05ml propyl silicate and 5ul methyl diphenyl hydroxyethyl silane evenly to form a precursor solution, slowly add it dropwise to the above solution, stir at room temperature for 1min; mix 0.3ml deionized water at 0.5ml / min Add dropwise to the above solution at a speed of 1, and stir at room temperature for 1 min; add 0.3 ml of ammonia water dropwise to the above solution at a speed of 1 ml / min, and stir at room temperature for 5 h to form organic SiO 2 (o) the ball;

[0064] (2) Add 0.01ml propyl silicate to the above solution, stir at room temperature for 20h to form inorganic SiO 2 Coated organic SiO 2 The structure of the ball is SiO 2 (o)SiO 2 (i) structure;

[0065] (3) Add 10ml of propi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com