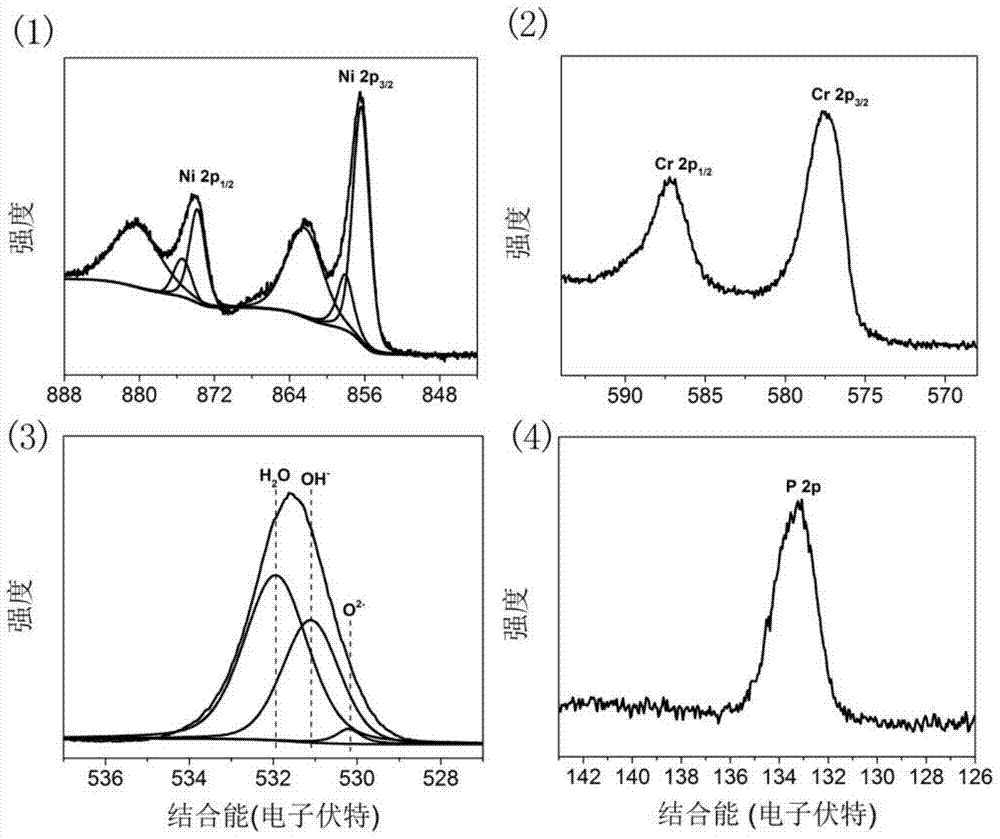

Semiconductor substrate/chromium-containing bimetallic alkaline phosphate photoelectrode and preparation method thereof

A metal base, phosphate light technology, used in electrodes, chemical instruments and methods, electrolysis components, etc., to achieve the effects of enhanced stability, simple operation, and enhanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A. Take by weighing nickel nitrate hexahydrate 0.6543g, potassium chromate 0.1456g, potassium nitrate 3.033g is dissolved in 100mL deionized water and is mixed with mixed salt solution;

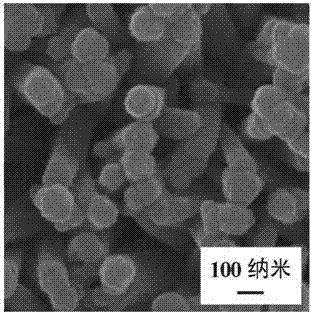

[0027] B. Transfer the mixed salt solution from step A to a single-chamber electrolytic cell, where the working electrode has an area of 1 cm 2 TiO 2 The substrate, the counter electrode is a platinum wire electrode, the reference electrode is an Ag / AgCl electrode, connected to an electrochemical workstation, and a potential of -0.4V is applied to the working electrode for electrodeposition for 50 seconds;

[0028] TiO 2 The substrate synthesis steps are: use acetone: isopropanol: water = 1:1:1 volume ratio solution to ultrasonically clean the FTO conductive glass sheet, and dry it naturally; prepare 6mL hydrochloric acid solution with concentrated hydrochloric acid and water at a volume ratio of 1:1 , add 100μL tetra-n-butyl titanate and stir evenly, transfer the solution to a 20m...

Embodiment 2

[0036] A. Take by weighing nickel nitrate hexahydrate 0.8724g, potassium chromate 0.1942g, potassium nitrate 4.044g is dissolved in 100mL deionized water and is mixed with mixed salt solution;

[0037] B. Transfer the mixed salt solution of step A to a single-chamber electrolytic cell, wherein the working electrode has an area of 1.5 cm 2 TiO 2 The substrate, the counter electrode is a platinum wire electrode, the reference electrode is an Ag / AgCl electrode, connected to the electrochemical workstation, and a potential of -0.4V is applied to the working electrode for electrodeposition, and the deposition is 50 seconds, in which TiO 2 The preparation steps of the substrate are the same as in Example 1;

[0038] C. Take out the working electrode after the end, fully wash it with deionized water, and dry it in a 70°C oven for 0.5 hours to obtain a new semiconductor substrate / chromium-containing double metal hydroxide photoelectrode;

[0039] D. with the newly made photoelectr...

Embodiment 3

[0044] A. Take by weighing zinc nitrate hexahydrate 0.6694g, potassium chromate 0.1092g, potassium nitrate 2.4264g be dissolved in 100mL deionized water and be mixed with mixed salt solution;

[0045] B. Transfer the mixed salt solution of step A to a single-chamber electrolytic cell, wherein the working electrode has an area of 1.8 cm 2 TiO 2 The substrate, the counter electrode is a platinum wire electrode, the reference electrode is an Ag / AgCl electrode, connected to the electrochemical workstation, and a potential of -0.4V is applied to the working electrode for electrodeposition, and the deposition is 50 seconds, in which TiO 2 The preparation steps of the substrate are the same as in Example 1;

[0046] C. Take out the working electrode after the end, wash it fully with deionized water, and dry it in an oven at 70°C for 1 hour to obtain a new semiconductor substrate / chromium-containing double metal hydroxide photoelectrode;

[0047] D. with the newly made photoelectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com