Modification method and composite material of natural graphite negative electrode material

A technology of natural graphite and negative electrode material, applied in battery electrodes, electrical components, electrochemical generators, etc., to prevent shedding, easy control, and strong lithium storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

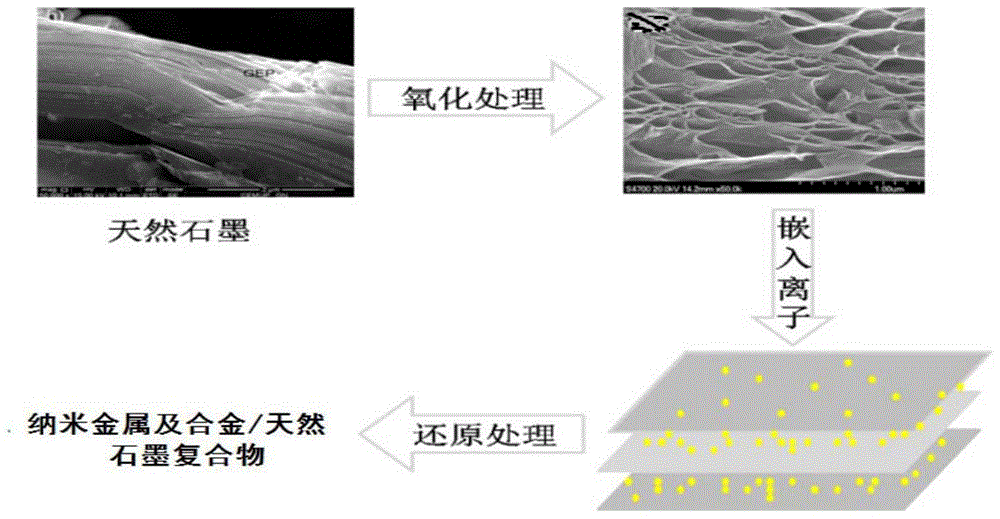

Method used

Image

Examples

Embodiment 1

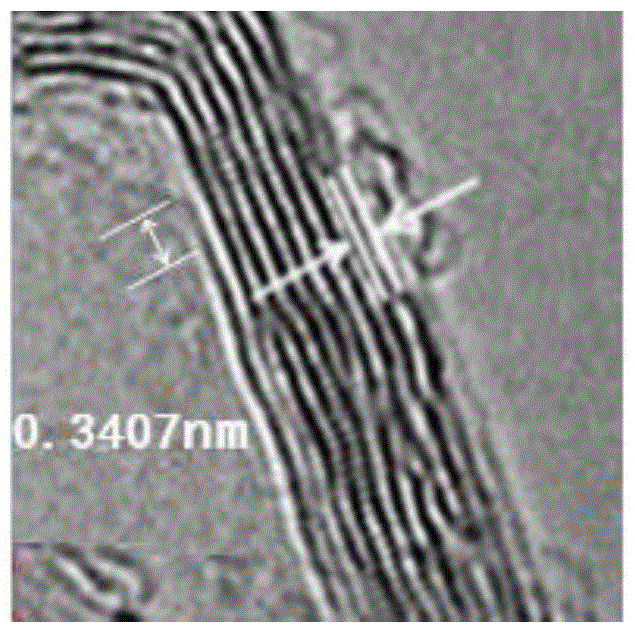

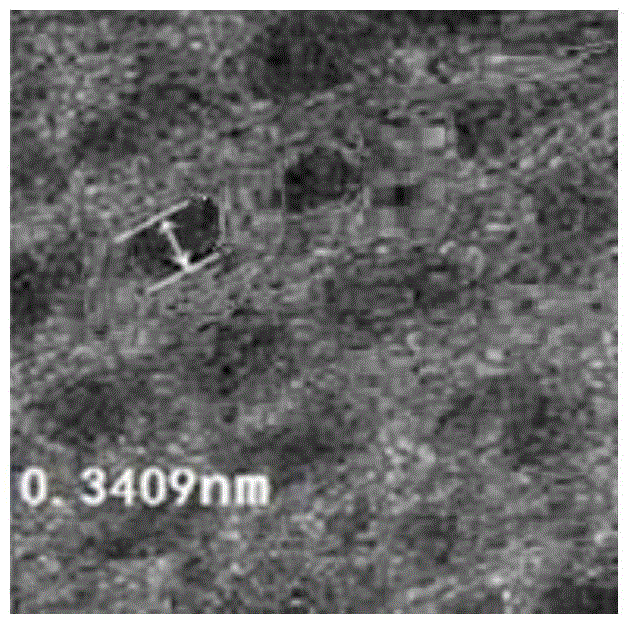

[0060] 1. Take 500g of natural graphite with a carbon content of 99%, a particle size D50 of 8.0 μm, and 1750g of formic acid solution electrolyte with a mass fraction of 60%, and the current density between the anode and the cathode is 10mA / cm 2 , electrolytically oxidize natural graphite for 4.0 hours to increase the distance between graphite layers to 0.4-0.7nm, wash with distilled water to a pH value of 6.5, filter, and dry at 60°C to obtain graphite oxide.

[0061] 2. Graphite oxide is prepared into a graphite oxide aqueous solution with a mass content of 30%, adding tin acetate and cobalt acetate with a molar concentration of metal ions of 0.1mol / L can intercalate mixed metal ion solutions, and the addition is 3% of the volume of the graphite oxide aqueous solution times, the frequency is 5.0KHz, and the power density is 0.30w / cm 2 , and ultrasonically dispersed for 60 minutes to obtain a mixed solution of graphite oxide metal ions.

[0062] 3. The nitrogen flow rate is...

Embodiment 2

[0068] 1. Take 500g of natural graphite with a carbon content of 99%, a particle diameter D50 of 11.0 μm, and 1900g of acetic acid solution electrolyte with a mass fraction of 56%. The current density between the anode and the cathode is 15mA / cm 2 , electrolytically oxidize natural graphite for 3.5 hours to increase the distance between graphite layers to 0.4-0.7nm, wash with distilled water to a pH value of 6.5, filter, and dry at 60°C to obtain graphite oxide.

[0069] 2. Graphite oxide is formulated into a graphite oxide aqueous solution with a mass content of 38%, and the molar concentration of metal ions added is 0.28mol / L tin acetate and nickel acetate intercalation mixed metal ion solution, and the addition is 3% of the volume of the graphite oxide aqueous solution times, the frequency is 4.2KHz, and the power density is 0.30w / cm 2 , and ultrasonically dispersed for 53 minutes to obtain a mixed solution of graphite oxide metal ions.

[0070] 3. The nitrogen flow rate i...

Embodiment 3

[0076] 1. Weigh 500g of natural graphite with a carbon content of 99%, a particle diameter D50 of 14.0 μm, and 2050g of phosphoric acid solution electrolyte with a mass fraction of 50%. The current density between the anode and the cathode is 20mA / cm 2 , electrolytically oxidize natural graphite for 3.0 hours to increase the distance between graphite layers to 0.4-0.7nm, wash with distilled water to a pH value of 6.5, filter, and dry at 60°C to obtain graphite oxide.

[0077] Two, the graphite oxide is formulated into a graphite oxide aqueous solution with a mass content of 46%, and the molar concentration of adding metal ions is 0.46mol / L tin sulfate and manganese sulfate intercalation mixed metal ion solution, and the addition is 3% of the volume of the graphite oxide aqueous solution times, the frequency is 3.4KHz, and the power density is 0.37w / cm 2 , and ultrasonically dispersed for 46 minutes to obtain a mixed solution of graphite oxide metal ions.

[0078] 3. The flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com