Preparation method of waterborne polyurethane emulsion modified by natural monosaccharide compound

A water-based polyurethane and compound technology, applied in the field of polymer chemical materials, can solve the problems of poor thermodynamic properties and low hardness of the adhesive film, and achieve the effects of low production cost, improved initial viscosity and stable product properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

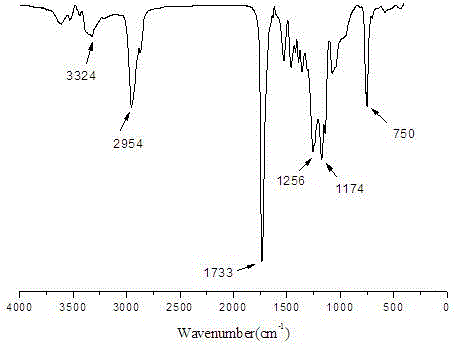

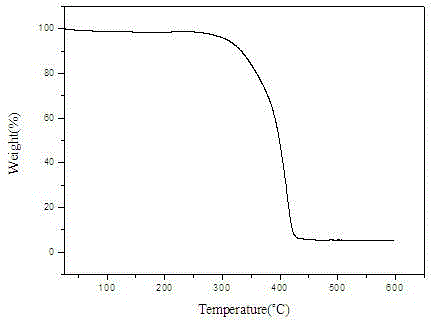

Image

Examples

Embodiment 1

[0024] (1) Add polycarbonate diol into a dry reactor, heat to melt the polyglycol in the reaction bottle, vacuumize and remove water at 120°C for 1 hour, then cool down to 80°C, dihydroxypropionic acid Add it into the reaction flask and stir for 10 min, then add isophorone diisocyanate into the reaction flask, and react at 80° C. for 4 h under the protection of nitrogen. Wherein the ratio of the amount of substance of isophorone diisocyanate and polycarbonate diol is 2:1, and the ratio of the amount of substance of dihydroxypropionic acid and polycarbonate diol is 3:100;

[0025] (2) Add the chain extender 1,4-butanediol to the reaction for 1 hour, then add fructose (dissolved in DMF) into the reactor, and react at 70°C for 3 hours, in which 1,4-butanediol and polycarbonate binary Alcohol is 0.5:1, and the ratio of the amount of fructose to polycarbonate diol is 1:1;

[0026] (3) Cool the reaction to 25°C, add triethylamine to adjust the pH value of the reaction to 7.5, add d...

Embodiment 2

[0028] (1) Add polybutylene adipate diol into a dry reactor, heat to melt the polyglycol in the reaction bottle, vacuumize at 120°C to remove water for 1 hour, and then cool down to 70°C , add dihydroxypropionic acid into the reaction flask and stir for 10min, then add isophorone diisocyanate and hexamethylene diisocyanate, and react at 70°C for 4h under nitrogen protection, wherein dihydroxypropionic acid and polybutylene adipate The ratio of the amount of substance of ester diol is 4:100, the ratio of the amount of substance of diisocyanate to polybutylene adipate is 1.6:1, and the ratio of isophorone diisocyanate to hexamethylene diisocyanate The ratio of the amount of substances is 1:1;

[0029] (2) Add the chain extender 1,4-butanediol to react for 0.5h, then add fructose (dissolved in DMF) into the reactor, and react at 70°C for 3h, in which 1,4-butanediol and polyadipic acid Butylene glycol ester glycol is 0.8:1, and the ratio of the amount of fructose and polybutylene...

Embodiment 3

[0032] (1) Add polybutylene adipate diol into a dry reactor, heat to melt the polyglycol in the reaction bottle, vacuumize at 120°C to remove water for 1 hour, and then cool down to 70°C , add dihydroxypropionic acid into the reaction flask and stir for 10min, then add isophorone diisocyanate and hexamethylene diisocyanate, and react at 70°C for 4h under nitrogen protection, wherein dihydroxypropionic acid and polybutylene adipate The ratio of the amount of substance of ester diol is 3:100, the ratio of the amount of substance of diisocyanate to polybutylene adipate is 2:1, and the ratio of isophorone diisocyanate to hexamethylene diisocyanate The ratio of the amount of substances is 1:1;

[0033] (2) Add the chain extender 1,4-butanediol to react for 0.5h, then add fructose (dissolved in DMF) into the reactor, and react at 70°C for 3h, in which 1,4-butanediol and polyadipic acid Butylene glycol ester glycol is 0.8:1, and the ratio of the amount of fructose and polybutylene a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com