Image acquisition semiconductor film for high-resolution mass-spectral imaging system, and preparation method and application of image acquisition semiconductor film

A high-resolution mass spectrometry and imaging system technology, applied in the field of high-resolution mass spectrometry imaging system image acquisition semiconductor thin film and preparation, can solve the problems affecting image resolution and mass accuracy, different ion initial velocities and directions, and non-reproducible spectra. and other problems, to achieve the effect of easy quality control and industrialization, simple method and stable nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

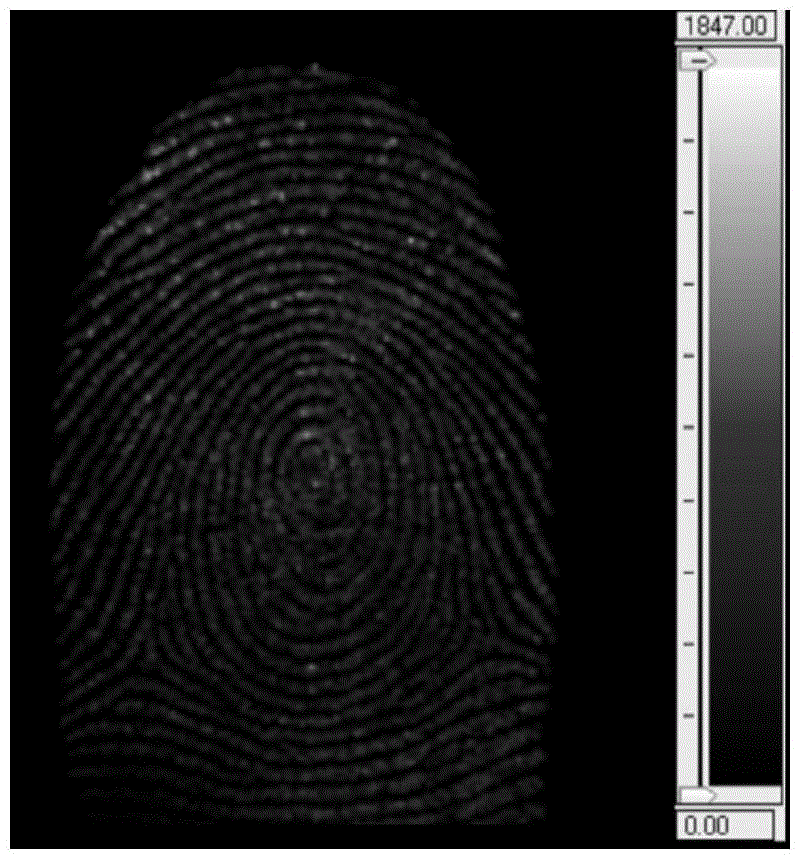

[0027] Preparation of high-resolution mass spectrometry imaging system image acquisition semiconductor thin film, which is used for imaging analysis of invisible fingerprints, the operation steps are as follows:

[0028] 1) Take a certain amount of (Bi) with an analytical balance 2 o 3 ) 0.07 (CoO) 0.03 (ZnO) 0.9 Semiconductor nanoparticles, such as 10mg, the type and amount of material can be determined according to different samples;

[0029] 2) burning the semiconductor nanoparticles obtained in step 1) in a muffle furnace at 350° C. for 1 hour to eliminate the pollution of the adsorbed organic molecules;

[0030] 3) The semiconductor nanoparticles obtained in step 2) are further ground with an agate mortar to make them uniformly dispersed;

[0031] 4) put the semiconductor nano-powder obtained in step 3) into the grinding tool of the tablet press, then put it into the tablet press, apply a pressure of 4800kg, and keep it under this pressure for 1 minute;

[0032] 5) ...

Embodiment 2

[0036] Preparation of high-resolution mass spectrometry imaging system image acquisition semiconductor film, which is used for mass spectrometry imaging of plant hormone jasmonic acid, the operation steps are as follows:

[0037] 1) Weigh a certain amount of (Bi2O3) with an analytical balance 0.07 (CoO) 0.03 (ZnO) 0.9 Semiconductor nanoparticles, such as 10mg, the type and amount of material can be determined according to different samples;

[0038] 2) burning the semiconductor nanoparticles obtained in step 1) in a muffle furnace at 350° C. for 1 hour to eliminate the pollution of the adsorbed organic molecules;

[0039] 3) The semiconductor nanoparticles obtained in step 2) are further ground with an agate mortar to make them uniformly dispersed;

[0040] 4) Put the semiconductor nano-powder obtained in step 3) into the grinding tool of the tablet press, then put it into the tablet press, apply a pressure of 2000kg, and keep it under this pressure for 1 minute to obtain a...

Embodiment 3

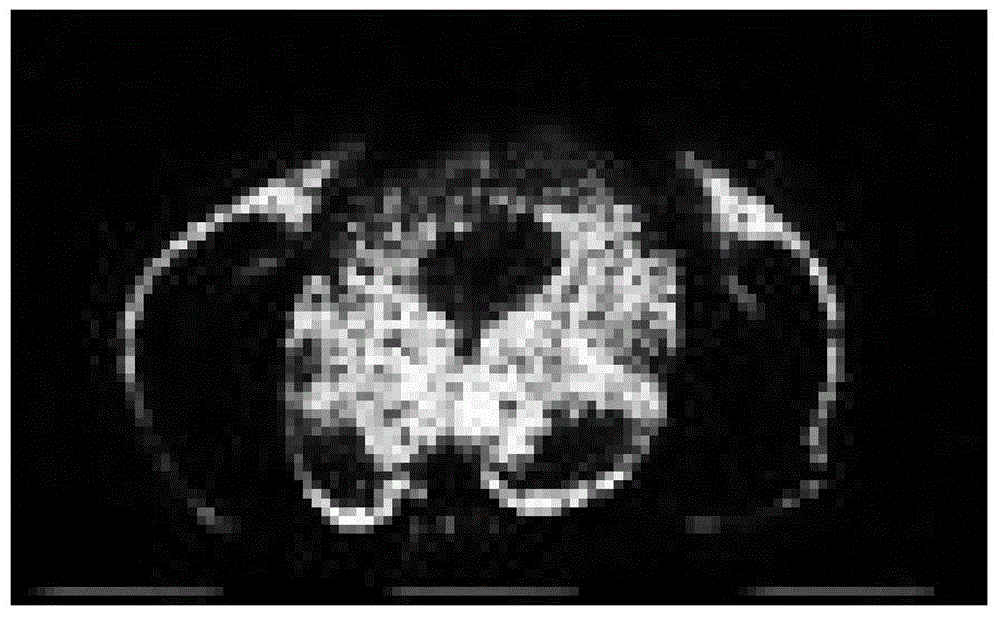

[0045] Preparation of semiconductor film for image acquisition of high-resolution mass spectrometry imaging system, which is used for mass spectrometry imaging of brain tissue cephalin, the operation steps are as follows:

[0046] 1) Weigh a certain amount of (Bi2O3) with an analytical balance 0.07 (CoO) 0.03( ZnO) 0.9 Semiconductor nanoparticles, such as 10mg, the type and amount of material can be determined according to different samples;

[0047] 2) burning the semiconductor nanoparticles obtained in step 1) in a muffle furnace at 350° C. for 1 hour to eliminate the pollution of the adsorbed organic molecules;

[0048] 3) The semiconductor nanoparticles obtained in step 2) are further ground with an agate mortar to make them uniformly dispersed;

[0049] 4) Put two-thirds of the semiconductor nano-powder obtained in step 3) into the grinding tool of the tablet press, then put it into the tablet press, apply a pressure of 4800kg, and keep it under this pressure for 1 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com