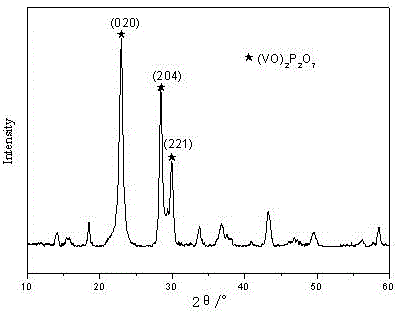

A kind of vanadium phosphorus oxide and preparation method thereof

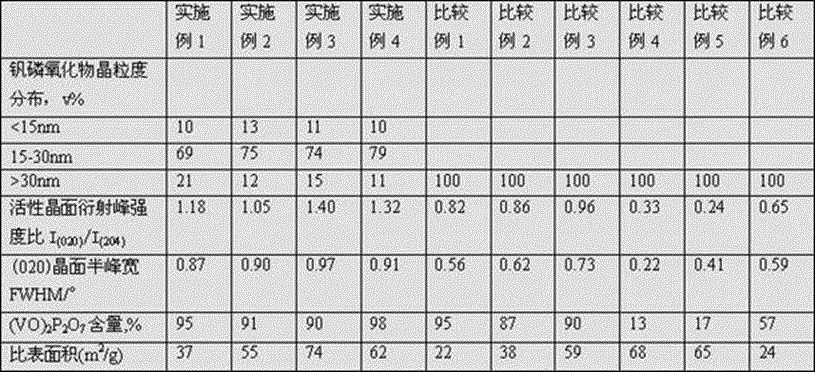

A technology of vanadium phosphorus oxide and vanadium pentoxide, which is applied in the direction of phosphorus compounds, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increasing catalyst manufacturing costs, insufficient particle size concentration, and uneven grain size distribution. Achieve the effects of stable catalyst structure, concentrated particle size distribution, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

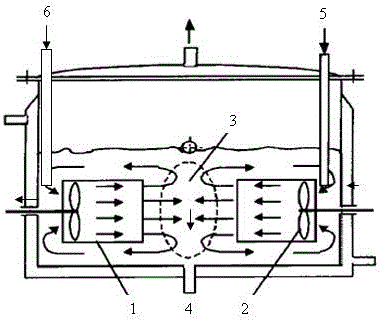

[0050] exist figure 1 In the impingement flow reactor shown, add isobutanol, benzyl alcohol mixture 500mL, isobutanol / benzyl alcohol volume ratio 10:1, silane coupling agent A-147 0.29g, start the impingement flow reactor, make stirring The rotation speed of the paddle reaches 1500r / min, and the reaction liquid passes through the guide tube to form an impingement flow. Raise the reaction temperature and keep it at 110±2°C, mix 29.53g of vanadium pentoxide and 149mL of isobutanol and benzyl alcohol in a FSH-2 high-speed homogenizer to form a suspension, so that the concentration of 85% Phosphoric acid 44.7g and the above-mentioned suspension were added into the reactor from two inlets of the impingement flow reactor at a certain flow acceleration rate, and the reaction time was maintained for 6 hours to complete the reaction. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed three times with a small amount of iso...

Embodiment 2

[0054] exist figure 1 In the impingement flow reactor shown, add 500mL of isobutanol and benzyl alcohol mixture, the volume ratio of isobutanol / benzyl alcohol is 15:1, 0.29g of silane coupling agent A-151, and 0.3g of ferric nitrate hexahydrate , zirconium nitrate 0.5g, start the impingement flow reactor, so that the rotation speed of the stirring blade reaches 2500r / min, and the reaction liquid passes through the guide tube to form an impingement flow. Raise the reaction temperature and keep it at 100±2°C, mix 29.53g of vanadium pentoxide and 149mL of isobutanol and benzyl alcohol in a FSH-2 high-speed homogenizer to form a suspension, so that the concentration of 100% Phosphoric acid 34.98g and the above-mentioned suspension were added into the reactor from two inlets of the impingement flow reactor at a certain flow acceleration rate, and the reaction time was maintained for 6 hours to complete the reaction. After the reaction solution was cooled to room temperature, it wa...

Embodiment 3

[0058] exist figure 1 In the impingement flow reactor shown, add isobutanol, benzyl alcohol mixed solution 500mL, isobutanol / benzyl alcohol volume ratio 20:1, silane coupling agent A-147 0.44g, start impingement flow reactor, make stirring The rotation speed of the paddle reaches 3500r / min, and the reaction liquid passes through the guide tube to form an impingement flow. Raise the reaction temperature and keep it at 97±2°C, mix 29.53g of vanadium pentoxide and 149mL of isobutanol and benzyl alcohol in a FSH-2 high-speed homogenizer to form a suspension, so that the concentration of 95% Phosphoric acid 33.47g and the above-mentioned suspension were added into the reactor from two inlets of the impingement flow reactor at a certain flow acceleration rate, and the reaction time was maintained for 8 hours to complete the reaction. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed with a small amount of isobutanol t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com