Preparation method for high-activity lanthanum phosphate nanorod and application of high-activity lanthanum phosphate nanorod as photocatalyst

A nanorod and lanthanum phosphate technology, which is applied in the field of nanomaterials, can solve the problems of rare earth phosphate photocatalytic properties that have not been reported, and achieve the effects of uniform size and distribution, low reaction temperature and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

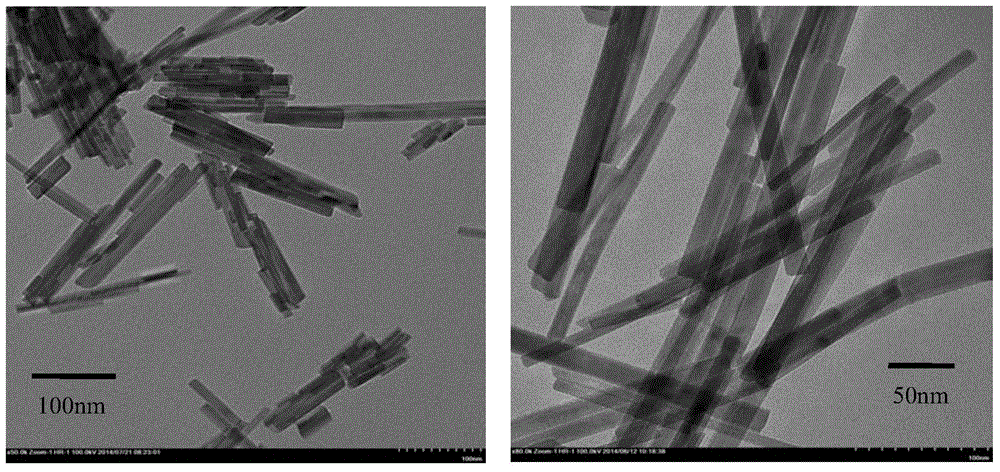

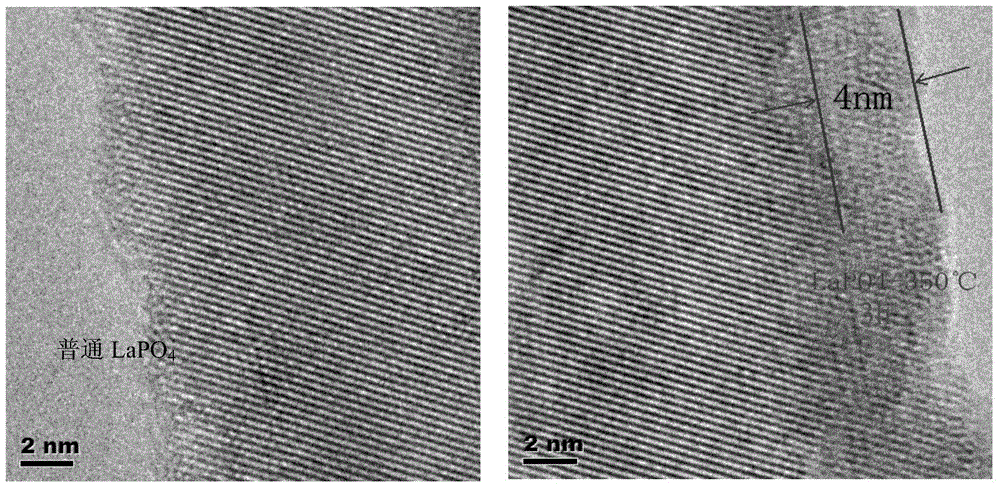

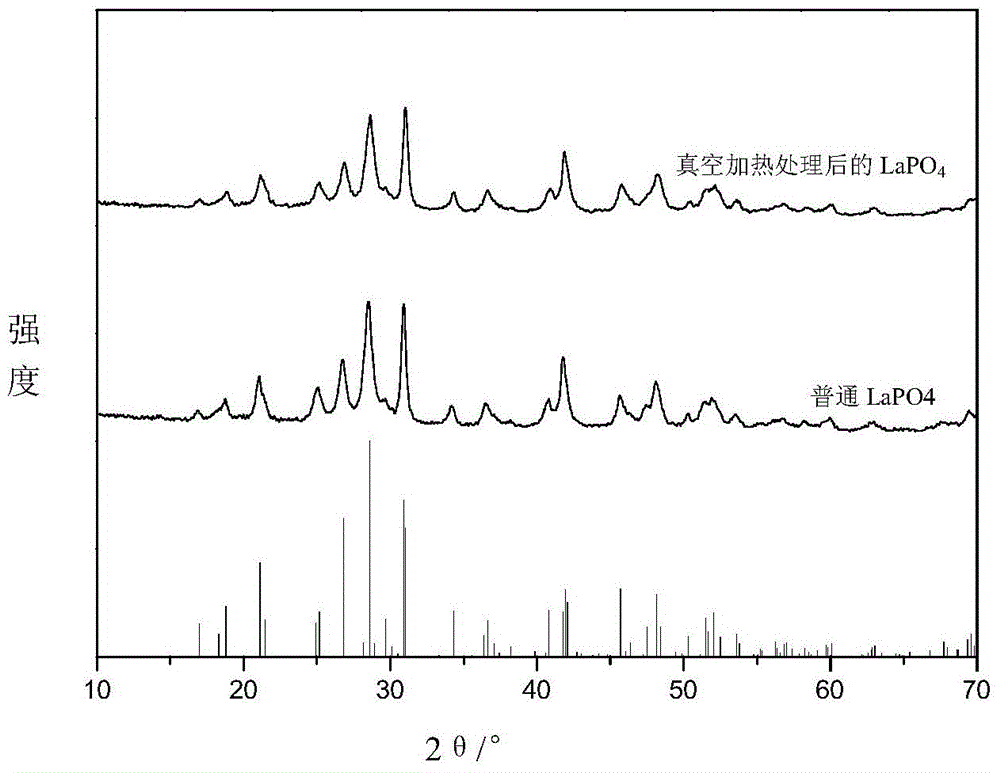

[0038] Embodiment 1, highly active LaPO 4 Preparation of nanorods

[0039] Weigh 3mmol of La(NO 3 ) 3 ·6H 2 O was dissolved in 15mL deionized water to obtain an aqueous solution of lanthanum nitrate (0.2M); weigh 3mmol of NaH 2 PO 4 2H 2 O was dissolved in 15 mL of deionized water to obtain an aqueous solution of sodium dihydrogen phosphate (0.2M); under magnetic stirring, the aqueous solution of sodium dihydrogen phosphate was added dropwise to the aqueous solution of lanthanum nitrate at a constant speed, and the stirring was continued for 1 h, and then transferred to 40 mL In a hydrothermal kettle, the filling degree is 75%, 180 ° C hydrothermal reaction for 12 hours, cooled to room temperature, the product is centrifugally washed to neutrality, and dried at 80 ° C for 24 hours to obtain a dried sample (that is, ordinary LaPO 4 Nanorods with a diameter of 10nm-20nm and a length of 20nm-200nm; take the dried sample and heat it at 350°C for 3 hours under vacuum to obtai...

Embodiment 2

[0045] Example 2, LaPO 4 Photocatalytic Activity Evaluation of Nanorods

[0046] Measure the common LaPO prepared in 25mg embodiment 1 respectively 4 Nanorods and vacuum-heated lanthanum phosphate nanorods were mixed with 50ml concentration of 1.0×10 -5 The mol / L MB solution was mixed in a test tube and stirred for 30 min in a dark room environment to make LaPO 4 Adsorption equilibrium and uniform dispersion were achieved in MB solution. Then place it in a 20W, 254nm ultraviolet light evaluation device for activity evaluation, and the light intensity when stable is 0.9mW / cm 2 , take a sample every 50min (3.0ml each time), centrifuge at a speed of 12000r / min for 10min, take the supernatant and measure the remaining concentration of MB with a Hitachi U-3010 UV-visible spectrophotometer, and calculate the degradation of MB The difference in ultraviolet photocatalytic activity between ordinary lanthanum phosphate nanorods and vacuum-heated lanthanum phosphate nanorods was inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com