Terbium ion doped yttrium phosphate barium green phosphor and preparation method thereof

A green fluorescent powder, yttrium barium phosphate technology, applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of low color rendering index, insufficient color temperature, etc., and achieve the effects of high luminous intensity, pure chromaticity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mix 3 mol of barium carbonate, 0.48 mol of yttrium oxide, 0.01 mol of tetraterbium heptoxide, and 3 mol of ammonium dihydrogen phosphate, and grind them evenly to obtain a mixture; heat the mixture to 300°C for 1.5 hours in an air atmosphere , naturally cooled and ground to obtain calcined material; the calcined material was heated to 1150 ° C for 10 hours in an air atmosphere, naturally cooled and ground evenly, and the chemical composition was obtained as Ba 3 Y 0.96 Tb 0.04 (PO 4 ) 3 green phosphor.

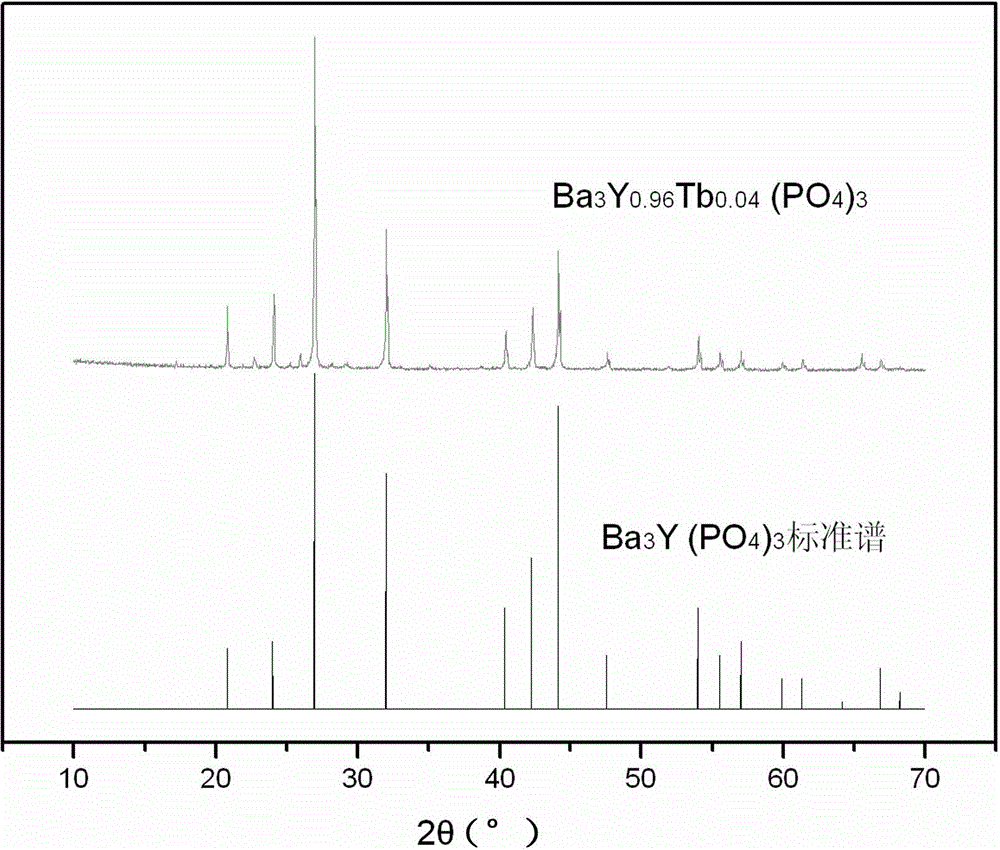

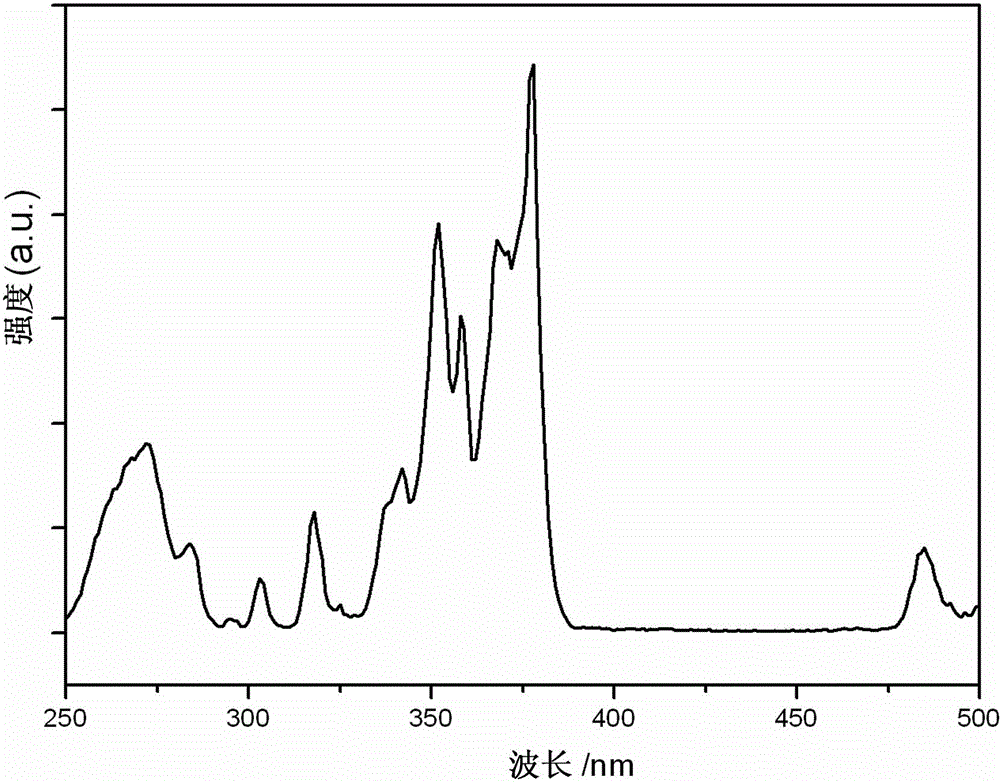

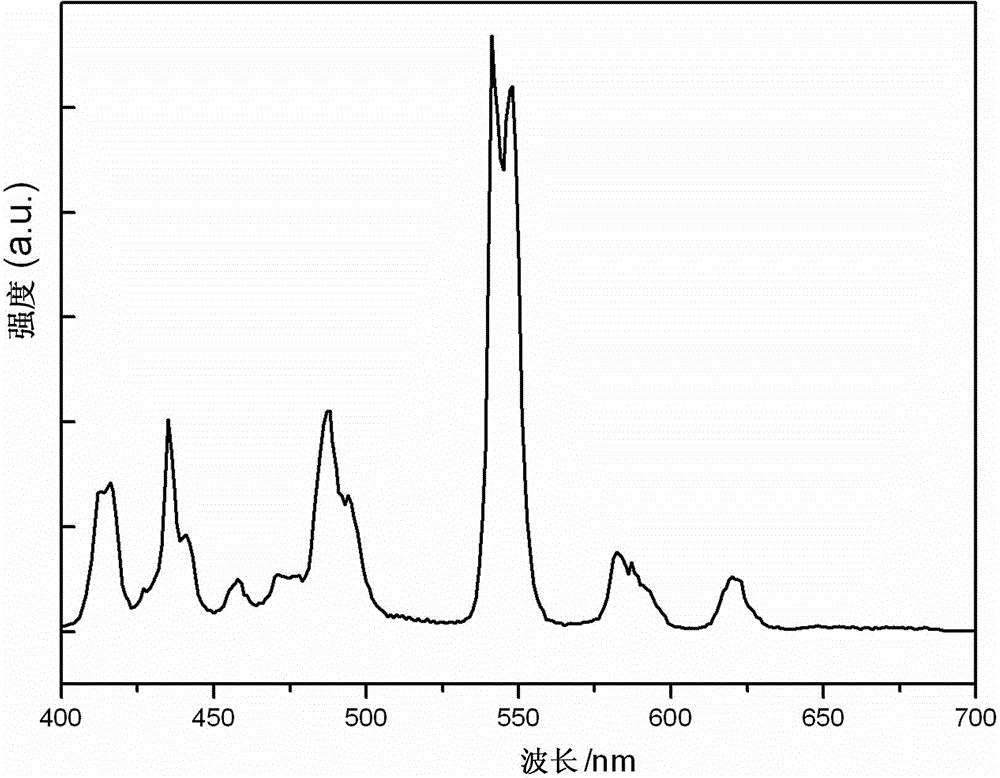

[0020] The X-ray powder diffraction pattern of the green phosphor material sample prepared in this embodiment is shown in the attached figure 1 . The absorption spectra of the material samples are shown in the attached figure 2 . The luminescence spectrum of the material sample under the excitation of 378nm wavelength is shown in the attached image 3 . From attached figure 2 And attached image 3 It can be seen that the Ba prepared in this example 3 Y 0...

Embodiment 2

[0022] Mix 3 mol of barium nitrate, 0.485 mol of yttrium oxide, 0.015 mol of terbium trioxide, and 3 mol of diammonium hydrogen phosphate, and grind them evenly to obtain a mixture; heat the mixture to 400°C for 2 hours in an air atmosphere , after natural cooling and grinding, the calcined material is obtained; the calcined material is heated to 1250 ° C for 8 hours in an air atmosphere, naturally cooled and ground evenly, and the chemical composition is obtained as Ba 3 Y 0.97 Tb 0.03 (PO 4 ) 3 green phosphor. The phosphor has bright green luminescence under ultraviolet light irradiation.

Embodiment 3

[0024] Mix 3 mol of barium carbonate, 0.9 mol of yttrium nitrate, 0.1 mol of terbium dioxide, and 3 mol of ammonium phosphate, and grind them evenly to obtain a mixture; the mixture is heated to 450°C for 4 hours in an air atmosphere, and then cooled naturally 1. After grinding, the calcined material is obtained; the calcined material is heated to 1350 ° C for 16 hours in an air atmosphere, cooled naturally, and ground to obtain a chemical composition of Ba 3 Y 0.9 Tb 0.1 (PO 4 ) 3 green phosphor. The phosphor has bright green luminescence under ultraviolet light irradiation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com