Strain for production of cyclodextrin glucosyltransferase and application of strain

A technology of bacterial strains and genetically engineered bacteria, applied in the fields of genetic engineering and enzyme engineering, enzyme engineering and genetic engineering, can solve problems such as distant kinship and difficult protein expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Cloning of Bacillus stearothermophilus α / β-CGTase coding gene and construction of expression vector

[0026] Bacillus stearothermophilus (preservation number CCTCC M 2013413) was cultured in LB liquid medium for 2 days, and the thalline was collected by centrifugation at 10,000 rpm, washed with sterile water, the collected precipitate was suspended in 500uL Tris-EDTA buffer, and 15uL lysozyme was added. Incubate at 37°C for 30min, then add 5uL RNase, incubate at 37°C for 30min, add 30µL 10% sodium dodecyl sulfate and 15µL proteinase K, incubate at 37°C for 60min, add 100uL of 5M NaCl and cetyltri 80 μL of methyl ammonium bromide, incubated at 65°C for 20 minutes, extracted with 700 μL of a mixed solvent with a volume ratio of phenol:chloroform:isoamyl alcohol of 25:24:1, centrifuged at 10,000 rpm, and the supernatant was mixed with 700 μL of chloroform:isoamyl alcohol Extract with a mixed solvent with an alcohol volume ratio of 24:1, centrifuge at 10,000 r...

Embodiment 2

[0031] Example 2: Transformation of Bacillus pumilus

[0032] 1) Fresh TM plate (TM medium: polypeptone 1%, beef extract 0.5%, yeast powder 0.2%, glucose 1%) pick Bacillus pumilus as Brevibacillus brevis (CCTCC AB 94025) and inoculate a single colony in 10ml TM culture cultured overnight.

[0033]2) Measure the OD in the shake flask, control the inoculum size, and make the OD of the medium after the inoculation complete. 600 Between 0.19-0.2. Medium is 50mL GM (peptone 0.5%, soybean peptone 0.5%, beef extract 0.5%, yeast extract 0.25%, glucose 0.5%, α-sodium glycerophosphate 1.9%, vitamin C 0.05%, MgSO 4 0.012%). 37°C, 200rpm culture to OD 600 =1.0 (about 3-4 hours).

[0034] 3) Take all the bacterial solution and bathe in ice water for 10 minutes, then centrifuge at 5000 rpm for 8 minutes at 4°C to collect the bacterial cells.

[0035] 4) Wash the cells with 40ml pre-cooled electroporation buffer ETM (9% sorbitol, 9% mannitol, 10% glycerol), centrifuge at 5000rpm, 8min,...

Embodiment 3

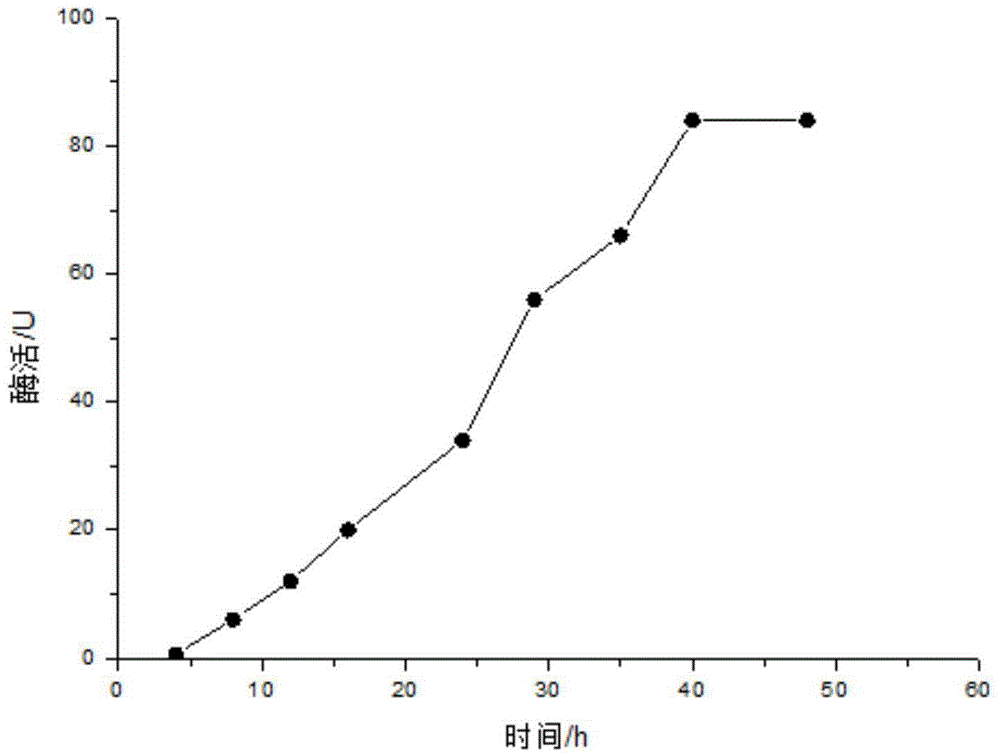

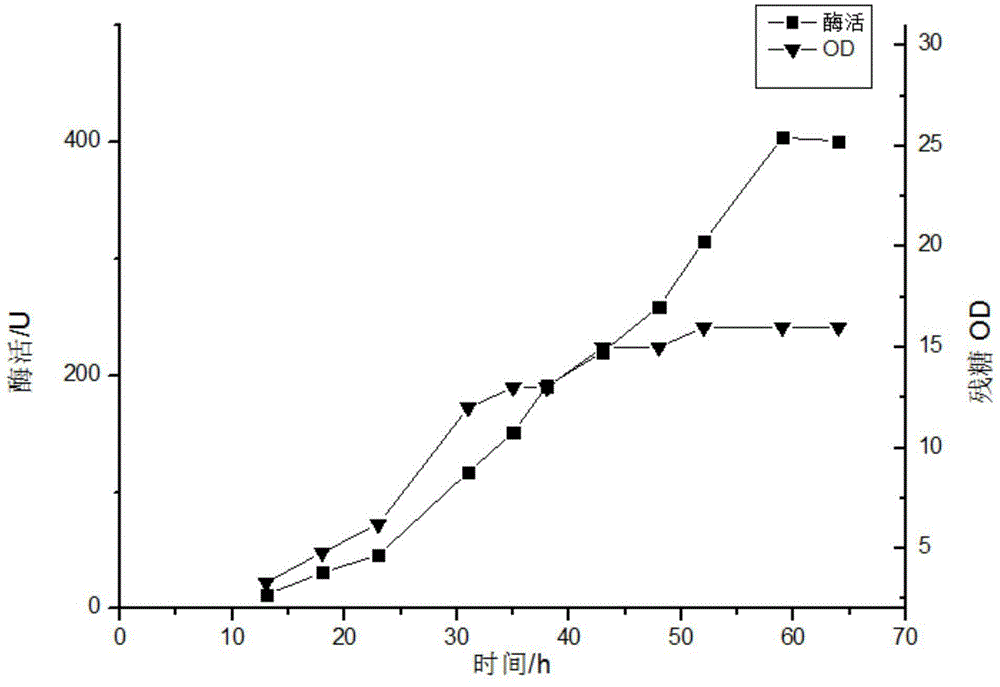

[0039] Embodiment 3: Shake flask fermentation produces enzyme

[0040] 1) Fermentation culture

[0041] The cyclodextrin glucosyltransferase-producing strain screened in Example 1 was inoculated in TM medium, and after culturing at 30°C for 12 hours, it was transferred to TM fermentation medium with a 5% inoculum size, and cultured at a constant temperature of 30°C for 44 hours. ~48h to produce enzyme. After the fermentation, the supernatant collected by centrifugation is the crude enzyme liquid.

[0042] TM medium (g / L): polypeptone 10, beef powder 5, yeast powder 2, glucose 10, pH7.0

[0043] 2) Determination of enzyme activity

[0044] The activity of the enzyme was determined by methyl orange method with soluble starch as substrate. Enzyme activity assay system: 2.5mL (containing soluble starch with a final concentration of 2%, 50mM KH 2 PO 4 -Na 2 HPO 4 Buffer, pH 6.0), add 100μL of appropriately diluted enzyme solution at 50°C and react for 10min, then add 200μl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com