Preparation method of nano porous copper oxide loaded precious metal catalytic material

A technology of nanoporous and catalytic materials, which is applied in the field of preparation of nanoporous catalytic materials, can solve the problems such as the inability to realize the loading of precious metal particles, and achieve the effects of high nanoporous structure stability, high catalytic performance and consumption saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

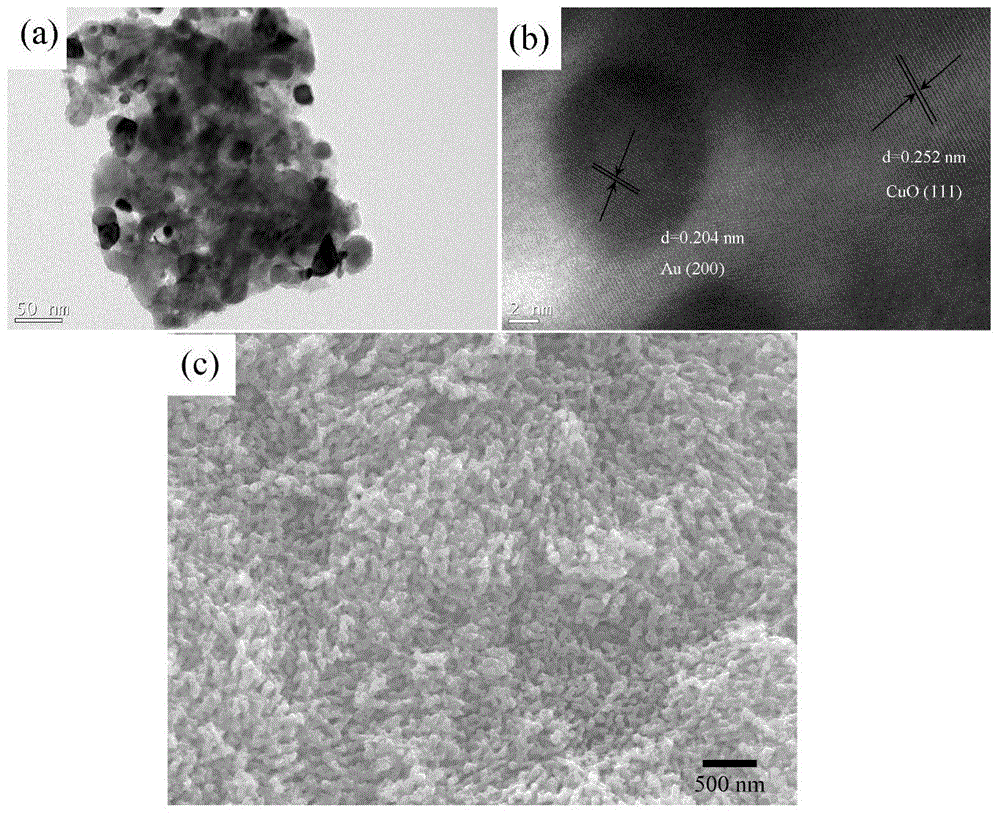

[0019] The raw material prepared by the molar ratio of 84.90% Al, 15.00% Cu and 0.10% Au is heated to 800°C by electric arc under vacuum to melt into a uniform precursor alloy and then prepared into ingot by ordinary casting method; the alloy ingot is cast at 0.1MPa Secondary melting and heating to 800°C in a melt quenching furnace under protective atmosphere conditions, and thin strips were prepared by melt quenching; the thin strips were dealloyed and corroded in a 10% NaOH aqueous solution for 10 hours, and there were no obvious bubbles Afterwards, it was washed repeatedly with deionized water and alcohol. After cleaning, it was placed in a constant temperature drying oven at 40°C for 4 hours, and then baked in an air atmosphere furnace at 600°C for 1 hour to prepare copper oxide-loaded nano-gold particles. Material. And it still has high structural stability and thermal stability after heat treatment at 600°C. After sintering, the size of the copper oxide is between 20-50...

Embodiment 2

[0021] Raw materials prepared with a molar ratio of 79.70% Al, 20.00% Cu and 0.30% Au are heated to 850°C by arc melting under an argon protective atmosphere to melt into a uniform precursor alloy and then prepared into ingots by ordinary casting; alloy casting The ingot was melted twice in a melt quenching furnace with a protective atmosphere of 0.1MPa and heated to 850°C, and a thin strip was prepared by the melt quenching method; the thin strip was dealloyed and corroded in a 5% NaOH aqueous solution for 12 hours , after there are no obvious bubbles, wash it repeatedly with deionized water and alcohol, dry it in a constant temperature drying oven at 40°C for 4 hours; then bake it in an air atmosphere furnace at 600°C for 1 hour to prepare copper oxide-loaded nanoparticles. Gold particle nanoporous catalytic material. And the obtained nanocomposite still has high structural stability and thermal stability after heat treatment at 750°C. The microstructure of the nanoporous c...

Embodiment 3

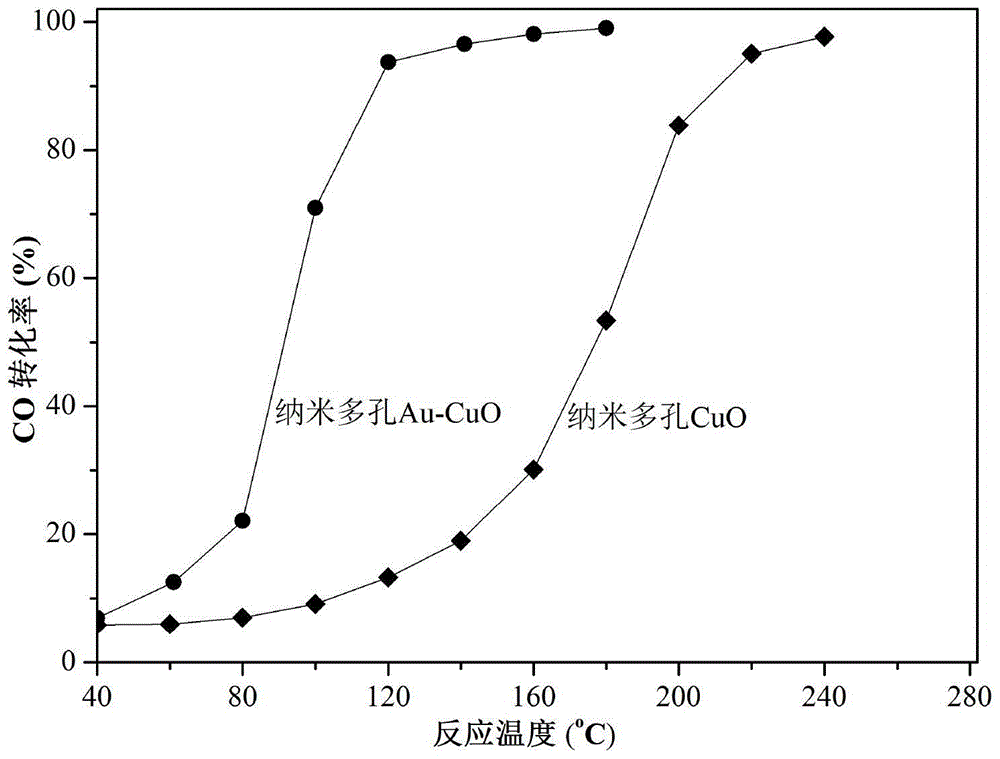

[0023] The raw material prepared by the molar ratio of 84.00% Al, 15.00% Cu and 1.00% Au is heated to 800°C by electric arc under 0.1MPa argon atmosphere and melted to form a uniform precursor alloy, and then prepared into ingot by ordinary casting method; alloy casting The ingot is melted twice in a melt quenching furnace with a protective atmosphere of 0.1MPa and heated to 800°C, and thin strips are prepared by the melt quenching method. The thin strip was dealloyed and corroded in 1% KOH aqueous solution for 6 hours. After there were no obvious bubbles, it was washed repeatedly with deionized water and alcohol. After roasting in an air atmosphere furnace at 750°C for 1 hour, the nanoporous catalytic material of copper oxide-loaded gold nanoparticles was prepared; compared with porous copper oxide, the catalytic material of nano-porous copper oxide-loaded gold particles had significantly enhanced CO catalytic oxidation performance, And it still has high structural stability ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com