Bisphenol compound and preparation method thereof, and polycarbonate composition prepared from bisphenol compound

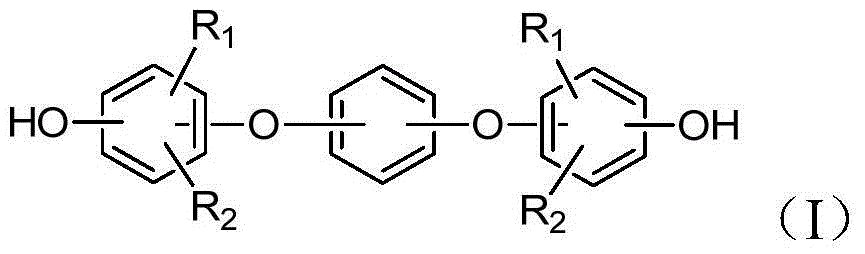

A technology of phenolic compound and polycarbonate, which is applied in the field of bisphenolic compound and its preparation, can solve the problems of mechanical or thermal performance reduction, the balance between processability and original performance, etc., so as to improve flexibility, The effect of avoiding the decrease of glass transition temperature Tg and avoiding the loss of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

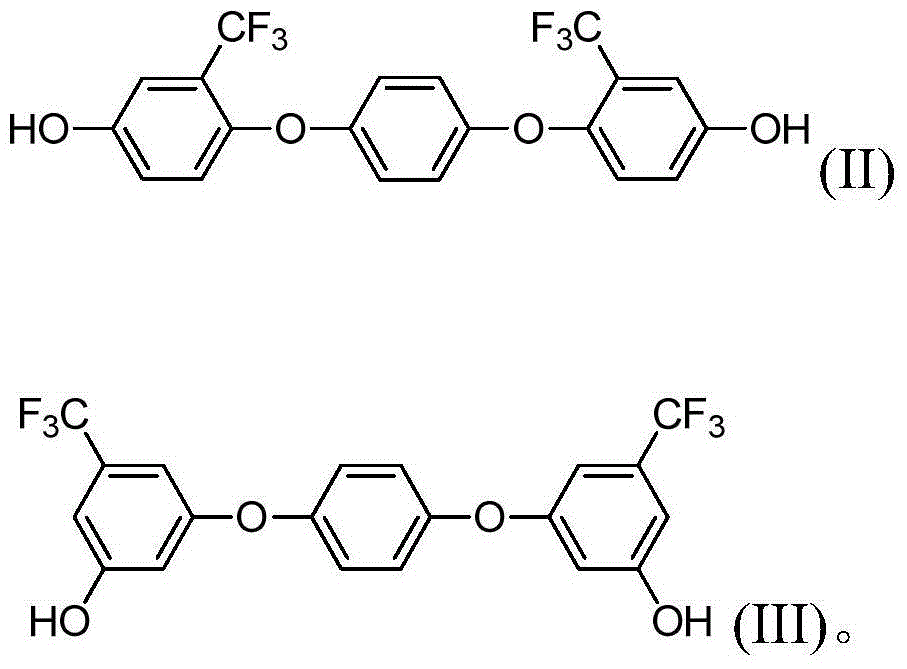

[0057] Synthetic bisphenol of formula (II) structure

[0058] In a 500ml three-necked flask, add 48.2g (0.2mol) 3-trifluoromethyl-4-bromophenol, 11.0g (0.1mol) p-diphenol, 27.6g (0.2mol) anhydrous potassium carbonate, 250ml dimethyl Formamide, the reaction system was stirred and reacted at 80° C. for 6 h under the protection of nitrogen. After cooling to room temperature, the reaction solution was poured into a mixed solution of dichloromethane and water, washed repeatedly with water, and the organic phase was separated, and the solvent was removed by rotary evaporation to obtain a crude product, which was recrystallized with ethanol to obtain 25.8 g of the target product.

[0059] Melting point: 137°C. H NMR spectrum (300MHz, CDCl 3 ): 5.33-5.35 (s, 2H), 6.89-6.92 (d, 2H), 7.07-7.10 (d, 2H), 7.32-7.35 (s, 2H), 7.39-7.42 (s, 4H).

Embodiment 2

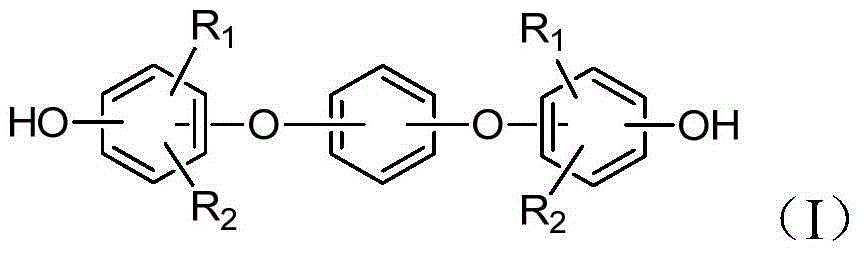

[0061] Synthetic bisphenol of formula (III) structure

[0062] In a 500ml three-necked flask, add 35.6g (0.2mol) 3-hydroxy-5-trifluoromethylphenol, 23.5g (0.1mol) p-dibromobenzene, 27.6g (0.2mol) anhydrous potassium carbonate, 250ml dimethyl sulfoxide, and the reaction system was stirred and reacted at 100° C. for 4 h under the protection of nitrogen. Cool to room temperature, pour the reaction solution into a mixed solution of dichloromethane and water, wash repeatedly with water, separate the organic phase, and remove the dichloromethane solvent by rotary evaporation to obtain a crude product, which is recrystallized with ethyl acetate to obtain 38.7 g of the target product .

[0063] Melting point: 128°C. H NMR spectrum (300MHz, CDCl 3 ): 5.40-5.43 (s, 2H), 6.79-6.82 (s, 2H), 7.08-7.11 (s, 2H), 7.21-7.23 (s, 2H), 7.40-7.43 (s, 4H).

Embodiment 3

[0065] Synthesis of homopolycarbonates prepared from bisphenols of formula (II):

[0066] Add 339.6g of formula (II) structure bisphenol, 956.0g of water and 66.0g of sodium hydroxide respectively in the mixing tank, mix and dissolve to form sodium phenate salt water phase; add 85.0g of liquid phosgene and 1320.5g of dichloromethane, mixed to form the organic phase. The sodium phenoxide salt phase and the organic phase are injected into the photochemical reactor composed of a static mixer at a flow rate of 45.3g / min and 46.8g / min respectively, the reaction temperature is 30°C, and after staying for 1.5min, they enter the same static mixer In the coupling reactor that constitutes, pour into the reactor simultaneously that concentration is the dichloromethane solution of 5wt% p-tert-butylphenol, the dichloromethane solution that concentration is 1.5wt% triethylamine and the concentration is 30wt% Sodium hydroxide aqueous solution, the flow rates of the three are 1.28g / min, 0.7g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com