Chlorantraniliprole aqueous-dispersion nano composite granule and preparation method thereof

A technology of chlorantraniliprole and nano-composite, applied in the field of pesticides, can solve the problem of single dosage form, achieve the effect of reducing dosage, optimizing microstructure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

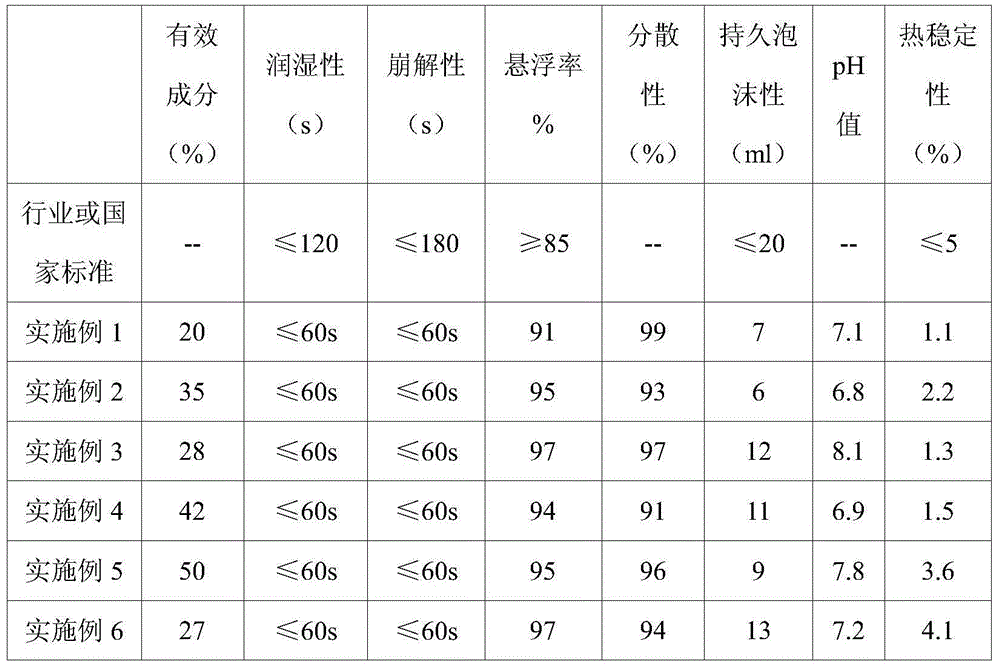

Embodiment 1

[0030] Chlorantraniliprole water-dispersible nanocomposite granules are prepared by the following method: Accurately weigh 20.0 kg of chlorantraniliprole loaded on nano sepiolite according to the formula requirements, and the wetting agent is 1.0 kg of alkylnaphthalene sulfonic acid Condensation polymer TERSPERSE2425, the dispersant is 10.0g of sodium lignosulfonate, the disintegrant is 1.0kg of urea, the filler is 67.9kg of white carbon black, add 15-20kg of water and mix it evenly to obtain a water suspension system, Grind to a fineness of 100-600nm with an ultra-fine wet grinder, add a certain amount of water and 0.1kg of binder to obtain a slurry for spraying, and then send the slurry to a drying tower for spray drying at 130°C Granulation, the residual moisture content of the product after granulation is 0.5-1.0wt%, and finally the material is combined and screened by a vibrating fluidized bed and a vibrating sieve to obtain chlorantraniliprole water-dispersed nanocomposit...

Embodiment 2

[0034] Chlorantraniliprole water-dispersible nanocomposite granules are prepared by the following method: Accurately weigh 35.0 kg of chlorantraniliprole loaded on nano-calcium carbonate according to the formula requirements, and the wetting agent is 2.5 kg of fatty alcohol polyoxyethylene Ether, the dispersant is 5.1kg of alkylnaphthalene sulfonate sodium formaldehyde condensate Morwet D-425, the disintegrant is 2.7kg of polyethylene glycol, 3.2kg of soluble starch, the filler is 24.1kg of bentonite, 24.5kg of Kaolin, add 15-20kg of water and mix it evenly to obtain a water suspension system, then grind it to a fineness of 100-600nm with an ultra-fine wet grinder, add a certain amount of water and 2.9kg of stabilizer to obtain a spray Slurry, then the slurry is sent to the drying tower, spray-dried and granulated at 140°C, the residual moisture content of the product after granulation is 0.5-1.0wt%, and finally the material is jointly screened by a vibrating fluidized bed and ...

Embodiment 3

[0038] Chlorantraniliprole water-dispersible nanocomposite granules are prepared by the following method: Accurately weigh 28.0 kg of chlorantraniliprole loaded on nano-diatomaceous earth according to the formula requirements, and the wetting agent is 1.0 kg of sulfonate Anionic surfactant TERWET1004, 2.0kg of alkylbenzene sulfonate as dispersant, 16.3kg of silica gel as disintegrating agent, 49.3kg of bentonite as filler, add 15-20kg of water and mix evenly to obtain a water suspension system , and then use an ultra-fine wet grinder to grind to a fineness of 100-600nm, add a certain amount of water and 3.4kg of synergist to obtain a slurry for spraying, and then send the slurry to a drying tower for drying at 160°C Spray drying and granulation, the residual moisture content of the product after granulation is 0.5-1.0wt%, and finally the material is screened by a vibrating fluidized bed and a vibrating sieve to obtain chlorantraniliprole water-dispersed nanocomposite granules w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com