Preparation method of high-strength glue

A high-strength, glue-based technology, applied in the direction of adhesives, non-polymer adhesive additives, grafted polymer adhesives, etc., can solve the problems of poor environmental performance, insufficient environmental protection, poor comprehensive performance, etc., and achieve superior comprehensive performance , Improve the effect of environmental protection and meet strict requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

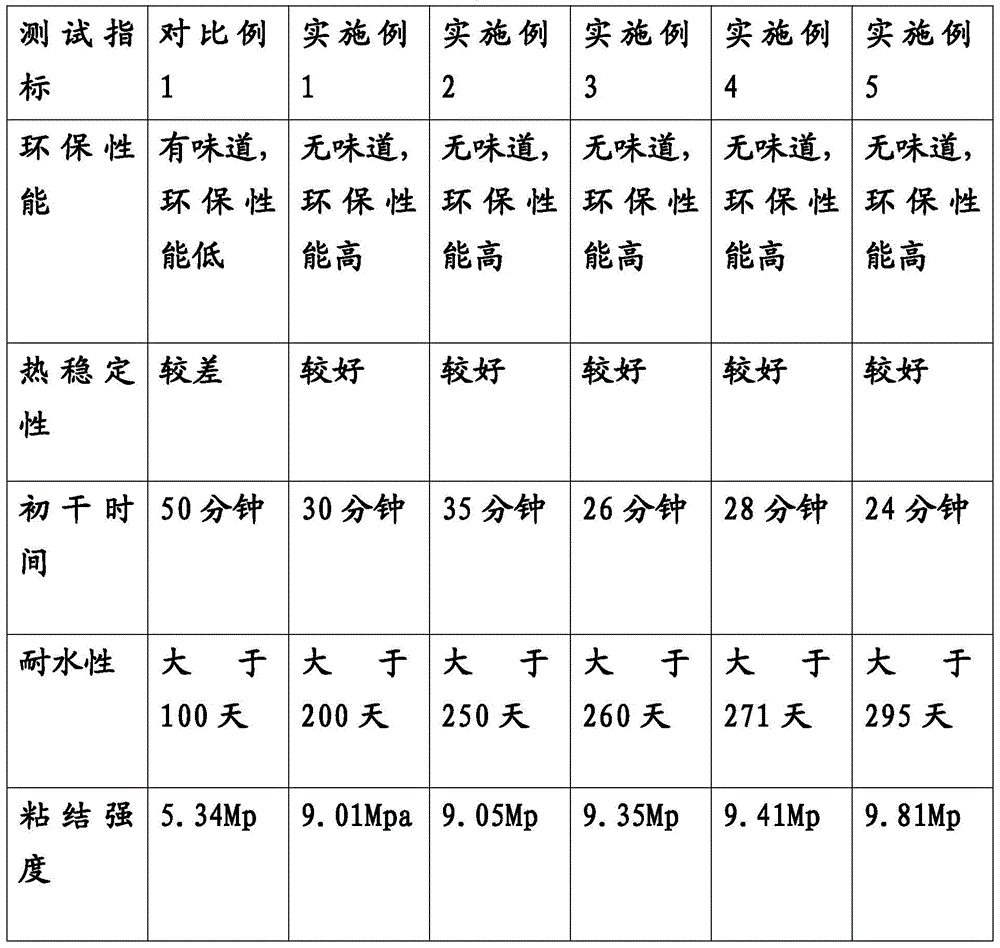

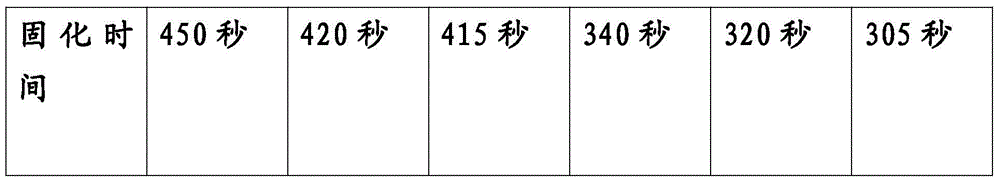

Examples

Embodiment 1

[0019] This embodiment relates to a preparation method of high-strength glue, and the glue includes the following components in parts by weight:

[0020] Polyvinyl acetate 700,

[0021] Vinyl acetate 300,

[0022] Polyvinyl alcohol 120,

[0023] Dibutyl phthalate 60,

[0024] Diethylene glycol dibenzoate 20,

[0025] Octanol 10,

[0026] Isopropanol 30,

[0027] Allyl methacrylate 10,

[0028] Ethylene glycol dimethacrylate 5,

[0029] Toluene diisocyanate 3,

[0030] Sodium bicarbonate 35,

[0031] water 1400,

[0032] Emulsifier 40, the emulsifier is sodium oleate (i.e. sodium octadecenoate);

[0033] Initiator 5, the initiator is ammonium persulfate.

[0034] All components involved in this example can be obtained through public commercial channels. The preparation method step of high-strength glue in the present embodiment is as follows:

[0035] Step 1, under stirring conditions, take 50-73% by weight of water (that is, the weight of the water taken accounts ...

Embodiment 2

[0041] This embodiment relates to a preparation method of high-strength glue. For specific steps, refer to Example 1. The glue includes the following components in parts by weight:

[0042] Polyvinyl acetate 1050,

[0043] Vinyl acetate 350,

[0044] Polyvinyl alcohol 145,

[0045] Dibutyl phthalate 100,

[0046] Diethylene glycol dibenzoate 40,

[0047] Octanol 15,

[0048] Isopropanol 45,

[0049] Allyl methacrylate 25,

[0050] Ethylene glycol dimethacrylate 10,

[0051] Toluene diisocyanate 7,

[0052] Sodium bicarbonate 50,

[0053] water 1500,

[0054] Emulsifier 50, the emulsifier is sodium dodecylbenzenesulfonate;

[0055] Initiator 10, the initiator is ammonium persulfate.

Embodiment 3

[0057] This embodiment relates to a preparation method of high-strength glue. For specific steps, refer to Example 1. The glue includes the following components in parts by weight:

[0058] Polyvinyl acetate 800,

[0059] Vinyl acetate 315,

[0060] Polyvinyl alcohol 125,

[0061] Dibutyl phthalate 80,

[0062] Diethylene glycol dibenzoate 25,

[0063] Octanol 12,

[0064] Isopropanol 35,

[0065] Allyl methacrylate 15,

[0066] Ethylene glycol dimethacrylate 7,

[0067] Toluene diisocyanate 4,

[0068] Sodium bicarbonate 39,

[0069] water 1450,

[0070] Emulsifier 45, the emulsifier is sodium dodecylbenzenesulfonate;

[0071] Initiator 6, the initiator is potassium persulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com