Chitosan microsphere simultaneously containing 5-fluorouracil and oleanolic acid derivative and preparation method of chitosan microsphere

A technology of chitosan microspheres and oleanolic acid, which is applied in the field of medicine, can solve problems such as drug combination and synergistic effects that have not been considered, and achieve increased passive targeting performance, good encapsulation efficiency, and improved bioavailability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Preparation of oleanolic acid succinate monoester (butylene oleate)

[0019] Add 1.14g (2.5mmol) of oleanolic acid and 1.25g (12.5mmol) of succinic anhydride into a three-necked flask, dissolve completely in toluene, and then add 1.53g (12.5mmol) of DMAP. Keep warm at 65°C, stir and react for 3 hours, expand the silica gel plate to detect the disappearance of raw material points (mobile phase: ethyl acetate:petroleum ether=3:1), stop the reaction. After the solvent was evaporated, ethyl acetate was dissolved, washed with hydrochloric acid solution at pH 1, and then washed with distilled water until neutral, and the ethyl acetate layer was spin-dried to obtain a white powder product with a yield of 95.0%.

Embodiment 2

[0020] Example 2 Optimization of the preparation process conditions of chitosan microspheres

[0021] Method: Dissolve chitosan in 1% (v / v) acetic acid solution to obtain chitosan acetic acid solution; dissolve butyl ester in ethanol to obtain 0.5% (m / m) butyl ester concentration Solution A; 5-fluorouracil was dissolved in distilled water to obtain solution B with a concentration of 5-fluorouracil (5-Fu) of 200 mg / ml; under rapid stirring conditions, solution A and solution B were added to chitosan acetate in proportion In the solution, stir and emulsify to obtain solution C; dropwise add sodium tripolyphosphate (TPP) solution, the volume ratio of sodium tripolyphosphate solution to solution C is 1:100, after the dropwise addition, continue to stir for 30 minutes to obtain the target Microspheres. G-50 gel chromatography: the encapsulation efficiency of 5-fluorouracil.

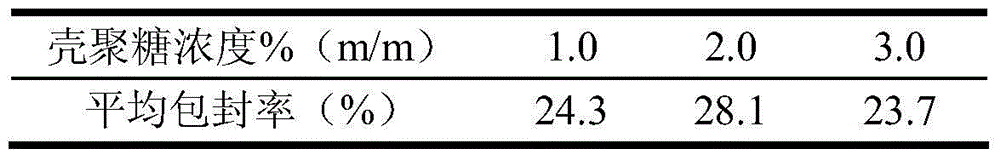

[0022] (1) The influence of chitosan concentration

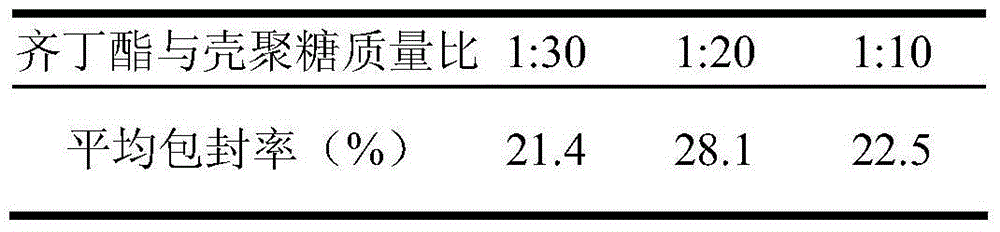

[0023] The mass ratio of butyl butyl ester to chito...

Embodiment 3

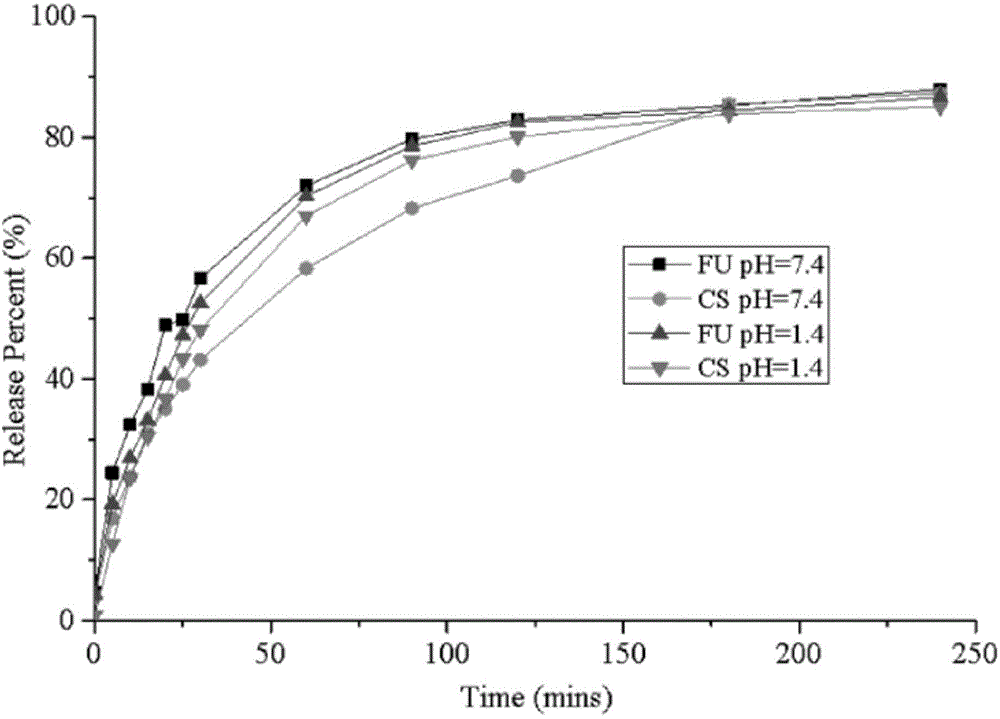

[0052] Example 3 Chitosan Microspheres Containing 5-Fluorouracil and Zibutyl Ester

[0053] (1) Preparation method

[0054] Chitosan is dissolved in the acetic acid solution of 1.0% (v / v), obtains the chitosan acetic acid solution that concentration is 2.00% (m / m); Dissolves butyl ester in ethanol, obtains the concentration of butyl ester of 0.5% (m / m) solution A; 5-fluorouracil was dissolved in distilled water to obtain solution B with a 5-fluorouracil concentration of 200 mg / ml; in proportion, the mass ratio of SOA to chitosan was 1:20, 5- The mass ratio of fluorouracil to chitosan is 1:10. Take solution A and solution B. Under rapid stirring conditions, add solution A and solution B to chitosan acetic acid solution, and stir and emulsify for 30 minutes to obtain solution C; 0.20% sodium tripolyphosphate (TPP) solution, the volume ratio of sodium tripolyphosphate solution to solution C is 1:50, after the dropwise addition, continue to stir for 30 minutes to obtain the targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com